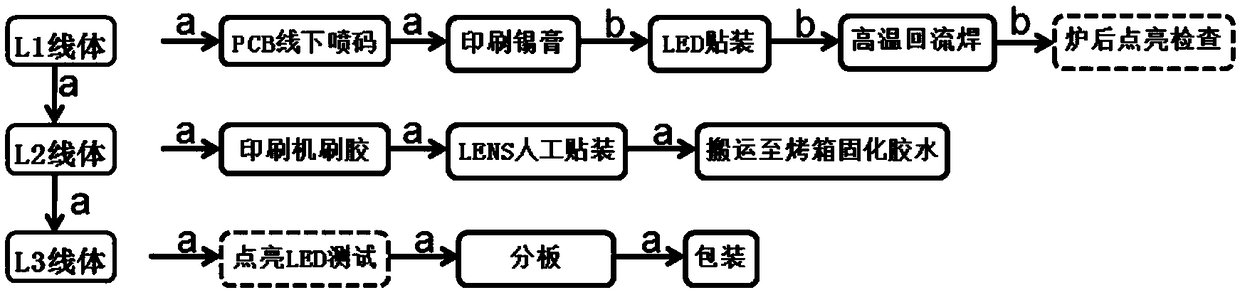

Production process of direct type backlight LED lamp strip

A technology of LED light bar and production process, which is applied to semiconductor devices of light-emitting elements, light sources, lighting devices, etc., which can solve the problems of low production efficiency, time-consuming, high labor costs, etc., so as to improve production efficiency and reduce on-line and off-line Turnaround time, the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described in conjunction with the following examples.

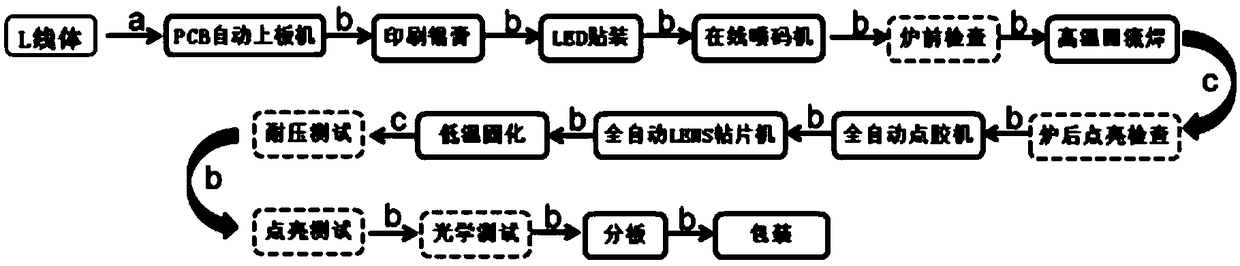

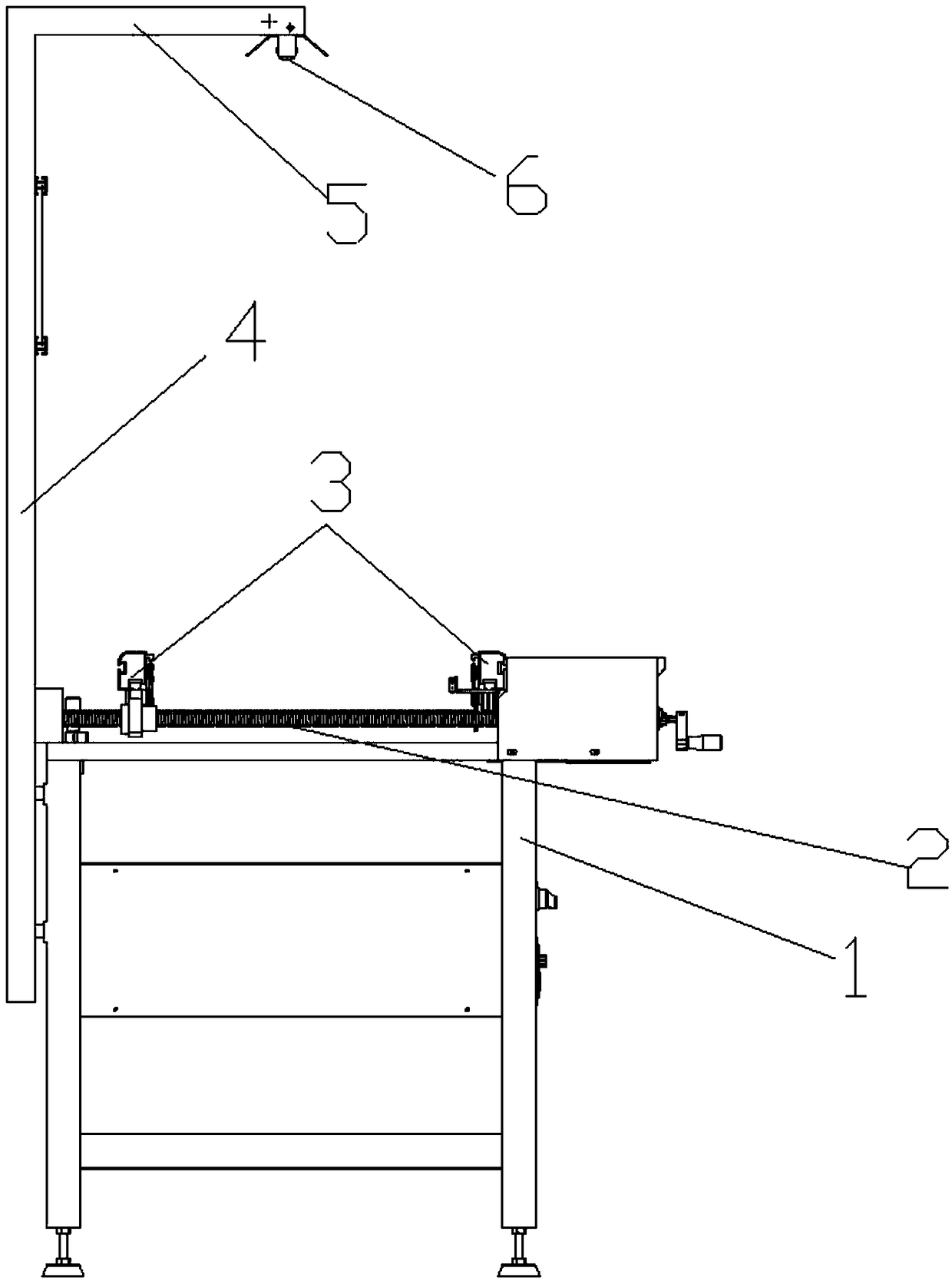

[0020] A specific embodiment of the production process of a direct-type backlight LED light bar of the present invention, such as figure 2 As shown, it includes the following steps: step a, automatically load the board, transport the PCB board to the automatic board loading machine, the automatic board loading machine positions the PCB board, arranges the board to form a circuit and generates a line signal; step b, prints solder paste, First thaw the solder paste for 4 hours, return the solder paste to temperature and stir it, and then put an appropriate amount on the stencil of the LED solder paste printing machine. 1. Print solder paste on the negative electrode position; step c, patch, the LED placement machine attaches the positive and negative electrode positions of the LED lamp beads to the positive and negative electrode positions printed with solder paste on the PCB, after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com