Novel LED lamp heat dissipation structure

A technology of LED lamps and heat dissipation structures, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problems of weak heat dissipation, heat conduction failure, thick heat dissipation fins, etc., and achieve stable and efficient heat dissipation , Avoid poor contact, strong heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

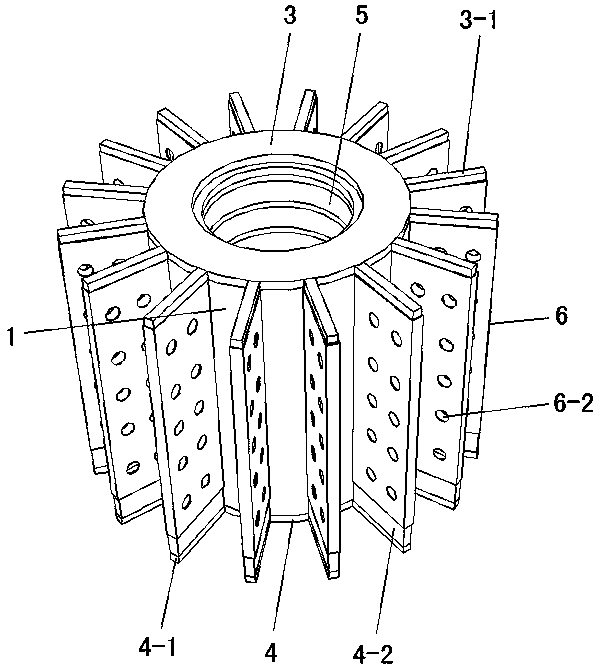

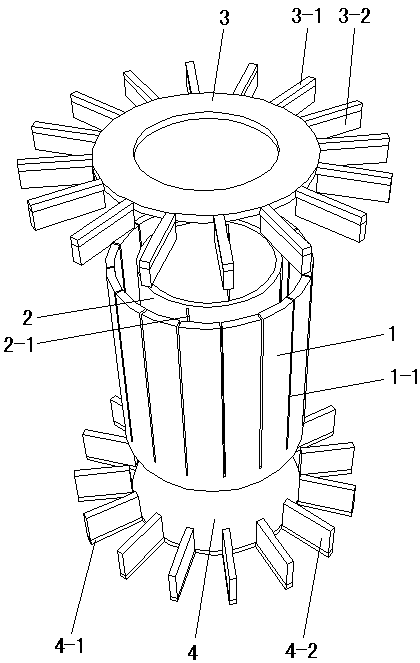

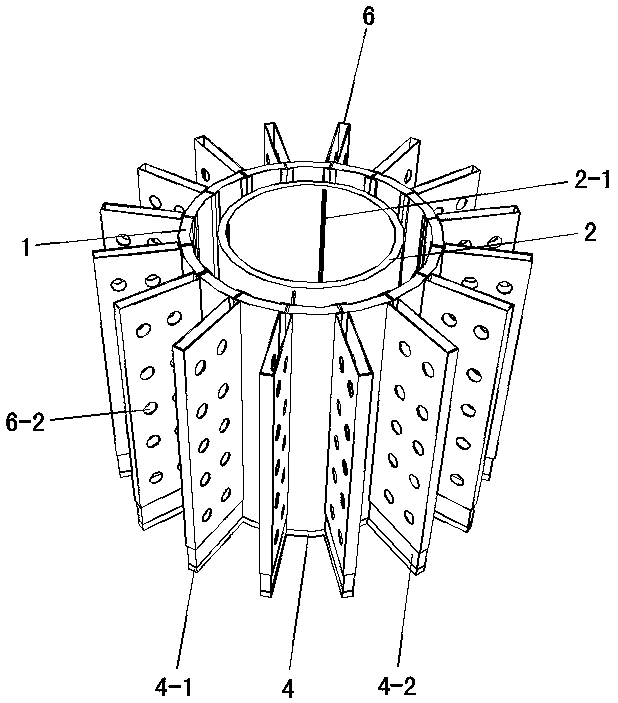

[0015] Specific implementation mode one: as Figure 1~Figure 5 As shown, the present invention discloses a new type of LED lamp heat dissipation structure, which includes a main body installation shell, a lamp holder 5, a plurality of heat dissipation fins 6 and a plurality of high thermal conductivity rectangular metal sheets 7, and the main body installation shell includes a coaxial interval The outer cylinder 1 and the inner cylinder 2 are sleeved, and the upper and lower ends of the outer cylinder 1 and the inner cylinder 2 are respectively bonded and fixed by the upper sealing ring 3 and the lower sealing plate 4, and the outer cylinder 1 Mercury is injected between the cylinder and the inner cylinder 2, and the liquid level of the mercury is lower than the upper surface of the outer cylinder 1 and the inner cylinder 2, and the upper end of the outer cylinder 1 wall is evenly provided with a plurality of vertical gaps along the circumferential direction One 1-1, each of t...

specific Embodiment approach 2

[0016] Specific implementation mode two: as figure 1 , 2 As shown, this embodiment is a further description of specific embodiment 1. The outer peripheral surface of the upper sealing ring 3 is uniformly fixed with a plurality of connecting rods-3-1 along the circumferential direction, and the plurality of connecting rods- 3-1 are arranged radially along the upper sealing ring 3 and are arranged in correspondence with a plurality of cooling fins 6 one by one. A positioning block 3-2 is fixed below each connecting rod 3-1, and each of the positioning blocks A 3-2 matching is inserted in the upper end of the corresponding cooling fin 6, the lower sealing plate 4 is a circular plate matching the lower end of the outer cylinder 1, and the circumferential surface of the lower sealing plate 4 is evenly fixed along the circumferential direction. Two connecting rods 4-1, the multiple connecting rods 4-1 are arranged radially along the lower sealing plate 4 and arranged in one-to-one ...

specific Embodiment approach 3

[0017] Specific implementation mode three: as Figure 4 As shown, this embodiment is a further description of Embodiment 1 or Embodiment 2, and each of the heat dissipation fins 6 is provided with a plurality of heat dissipation holes 6-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com