Anti-splash device for screw extruder

A technology of squeezing dryer and anti-splashing liquid, which is applied in drying, drying solid materials, lighting and heating equipment, etc. It can solve the problems of wasting water resources, production decline, environmental pollution, etc., and reduce labor time and labor intensity , the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

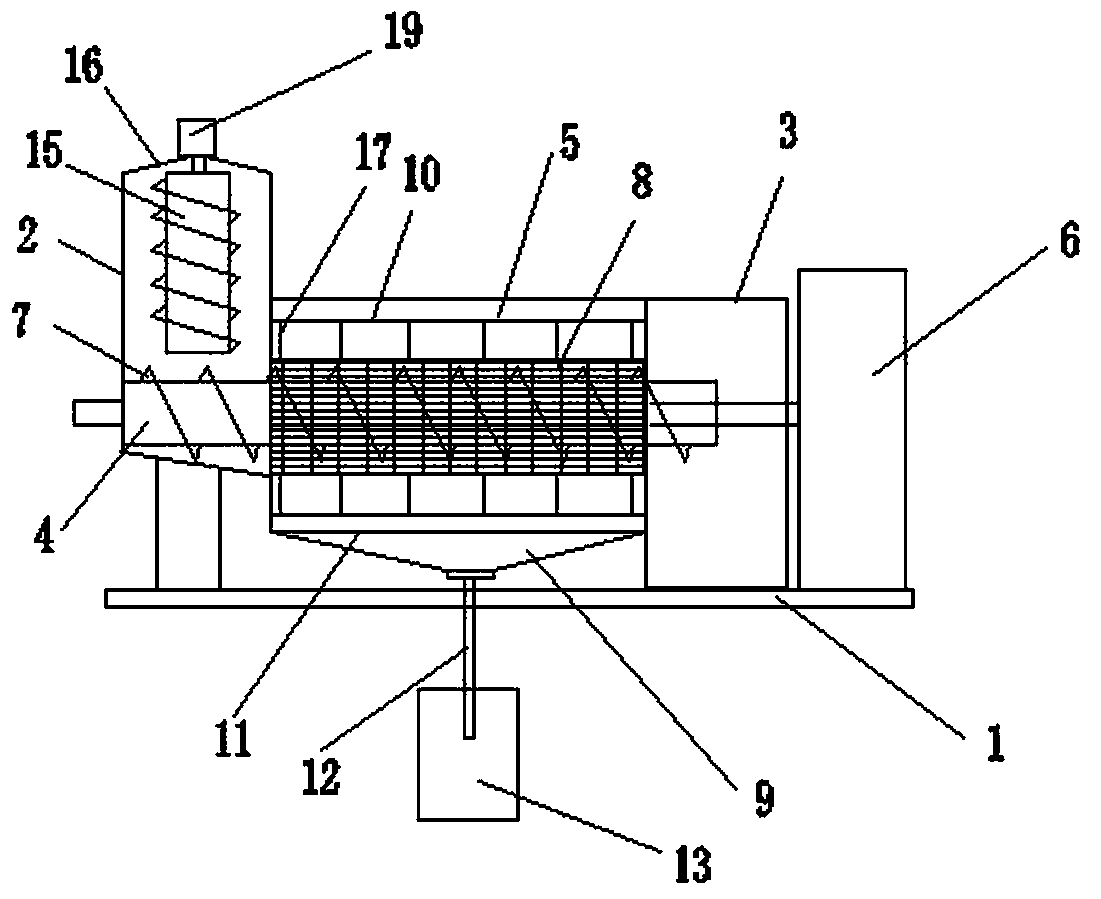

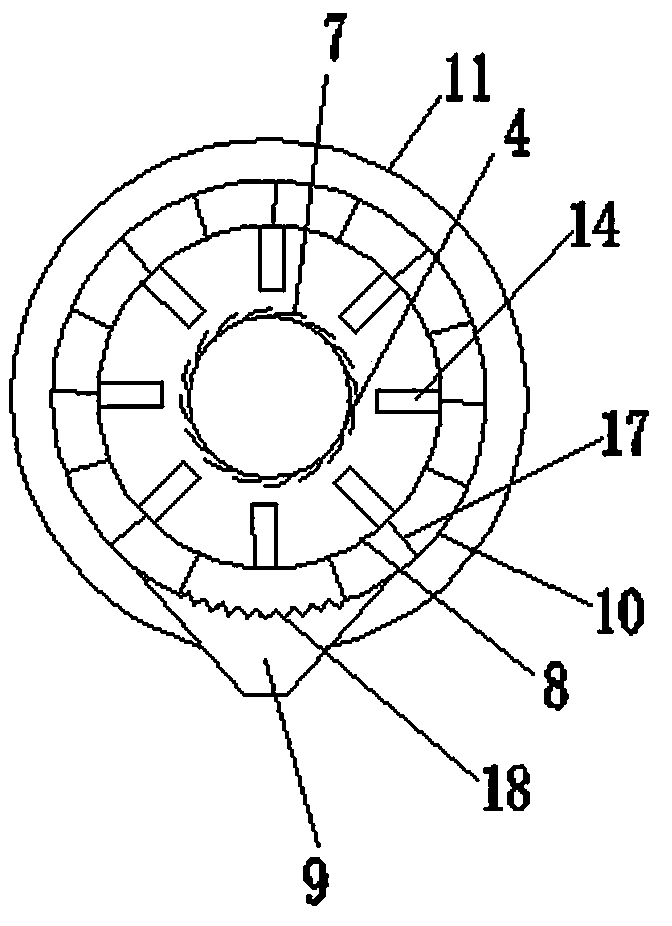

[0020] Embodiment 1: as figure 1 As shown, a screw squeezer anti-splash device includes a machine base 1, a feed box 2, a discharge box 3, a screw spindle 4, a water filtration system 5 and a transmission system 6, the feed box 2, the discharge box Material box 3, screw spindle 4, water filtration system 5 and transmission system 6 are all arranged above machine base 1, and feed box 2, water filtration mechanism 5, discharge box 3, and transmission system 6 are arranged in sequence from left to right; The main shaft 4 is located in the feed box 2, the water filtration system 5 and the discharge box 3. One end of the screw main shaft 4 is connected to the transmission mechanism 6, and the other end passes through the feed box 2 and has an opening. The screw main shaft 4 is provided with a helical impeller 7, The screw main shaft 4 is a hollow cylinder, and the inside of the screw impeller 7 is hollow. 4 is fed with high-pressure air or water flow, so that the materials adherin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com