Chassis dynamometer test bench driven by permanent magnet synchronous motor

A permanent magnet synchronous motor and chassis dynamometer technology, which is used in the testing of machine/structural components, vehicle testing, measuring devices, etc., can solve the problems that each wheel cannot be accurately tested, the mechanism is complex, etc., to achieve convenient installation, The effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

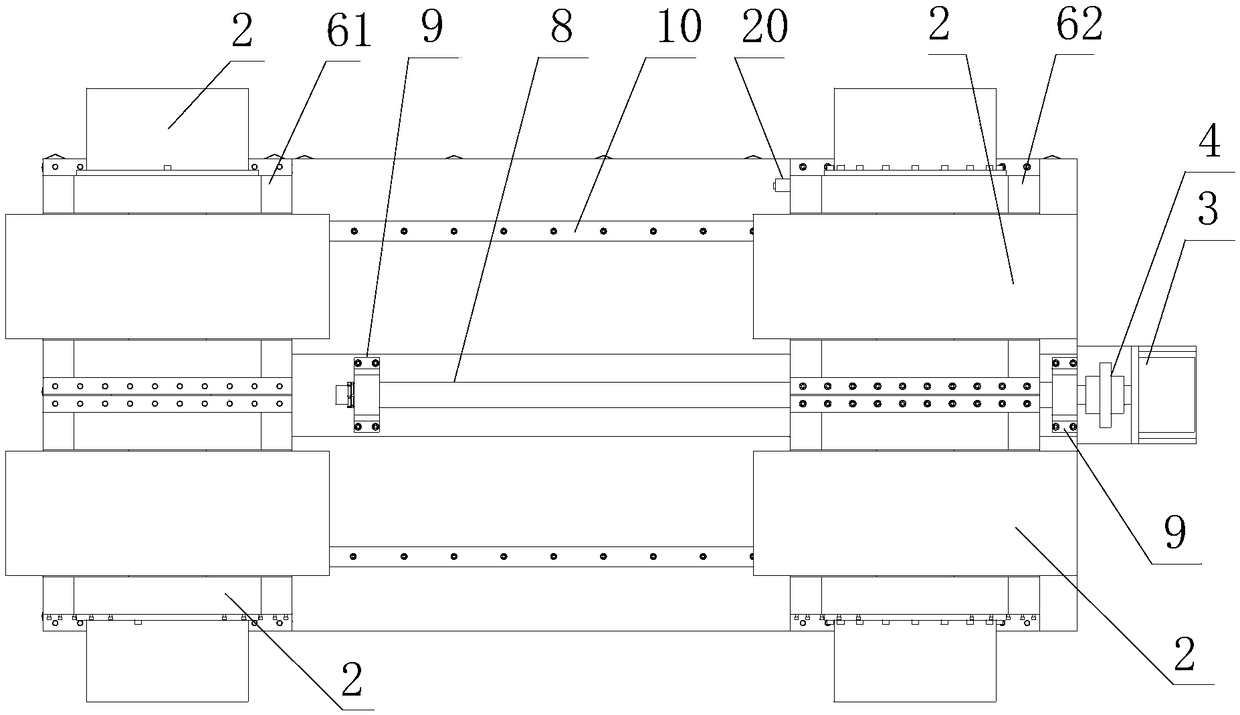

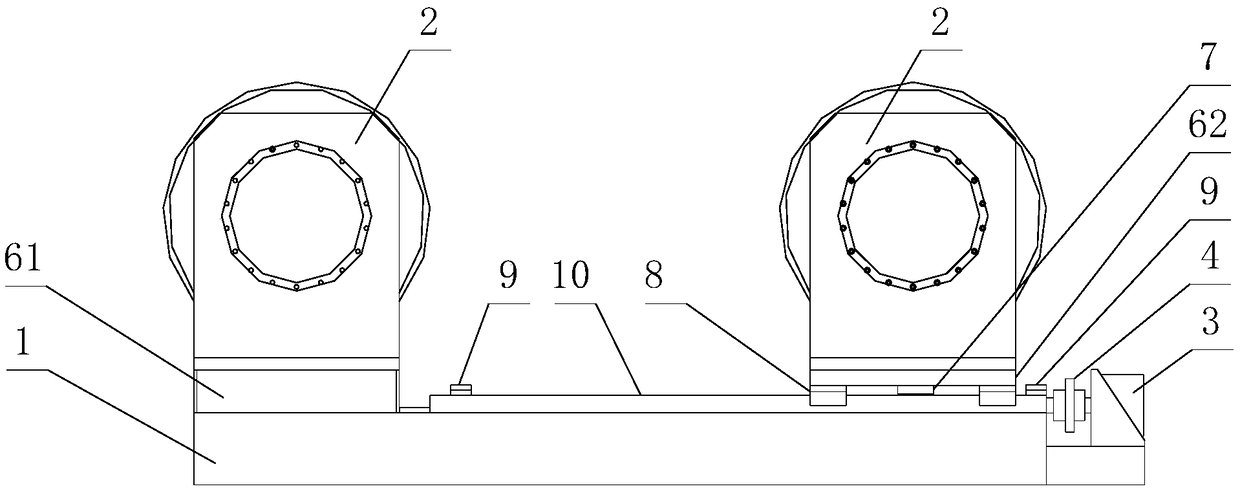

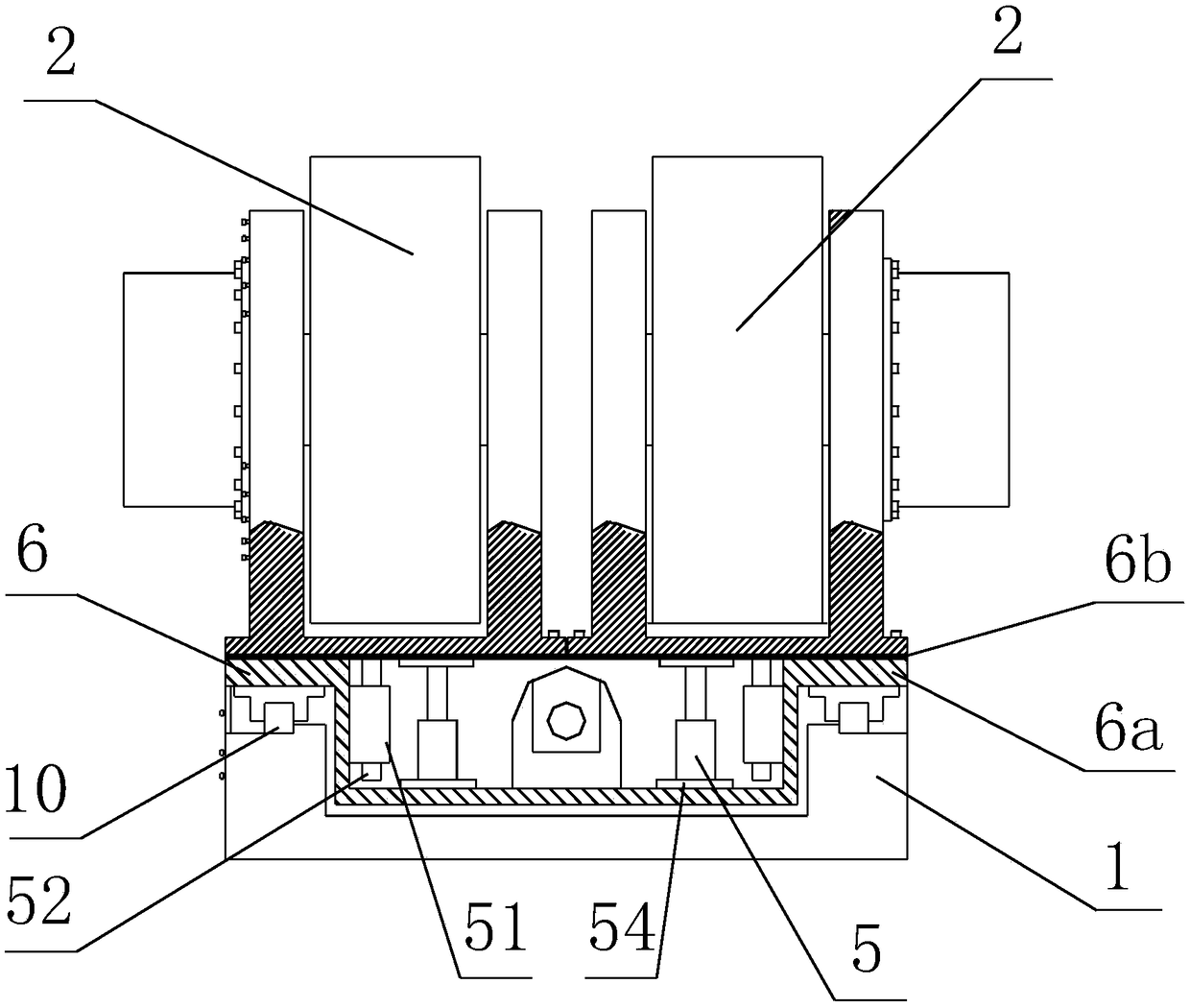

[0030] Such as Figure 1-6 As shown, a chassis dynamometer test bench driven by a permanent magnet synchronous motor includes a dynamometer 2, a base 1, a slide rail 10 arranged on the base, a pushing mechanism, a lifting mechanism 5, and a mounting seat 61 and mounting base 2 62; wherein mounting base 1 61 is fixed on one end of base 1, mounting base 2 62 is slidably installed on the slide rail 10 through the slider provided at its lower part; the dynamometer 2 includes four , work independently of each other, driven by a permanent magnet synchronous motor, and controlled by an all-electric inertia system; two of the dynamometers 2 are installed on the first mounting seat 61; the pushing mechanism is used to push the second mounting seat 62 along the The slide rail 10 moves; the lifting mechanism 5 is used to adjust the height of the dynamometer 2 from the ground.

[0031] Preferably, the dynamometer 2 includes a base 21, a main shaft 22, an encoder 24, a torque measuring de...

Embodiment 2

[0034] Such as Figure 7 As shown, a chassis dynamometer test bench driven by a permanent magnet synchronous motor includes a dynamometer 2, a base 1, a slide rail 10 arranged on the base, a pushing mechanism, a lifting mechanism 5, and a mounting seat 61 and mounting base 2 62; wherein mounting base 1 61 and mounting base 2 62 are all slidably installed on the slide rail 10 through the slide blocks provided at the respective lower parts; the dynamometer 2 includes four sets, which work independently of each other. Driven by a permanent magnet synchronous motor, controlled by an all-electric inertia system; two of the dynamometers 2 are installed on the first mounting base 61, and the other two are installed on the second mounting base 62; the pushing mechanism is used to push the The mounting base 6 moves along the slide rail 10; the lifting mechanism 5 is used to adjust the height of the dynamometer 2 from the ground.

[0035] Preferably, the dynamometer 2 includes a base 2...

Embodiment 3

[0038] Such as Figure 8 As shown, a chassis dynamometer test bench driven by a permanent magnet synchronous motor includes a dynamometer 2, a base 1, a slide rail 10 arranged on the base, a pushing mechanism, a lifting mechanism 5, and a mounting seat 61 , Mounting seat 2 62 and mounting seat 3 63; wherein mounting seat 1 61, mounting seat 2 62 and mounting seat 3 63 are all slidably installed on the slide rail 10 through the sliders provided at the respective lower parts; the dynamometer 2 includes six units, working independently of each other, driven by a permanent magnet synchronous motor, and controlled by an all-electric inertia system; two of the dynamometers 2 are installed on the same mounting base 1 61, and two are installed on the mounting base 2 62, the remaining two are installed on the second mounting base 62; the pushing mechanism is used to push the mounting base 6 to move along the slide rail 10; the lifting mechanism 5 is used to adjust the distance between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com