Energy storage transmission mechanism and rotary switch operating device using the energy storage transmission mechanism

A transmission mechanism and energy storage technology, which is applied to the power device inside the switch, electric switch, contact operating mechanism, etc., can solve the problems of poor operation feel, broken transmission parts, and short service life, so as to improve the effective power, Effects of reduced mechanical load and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

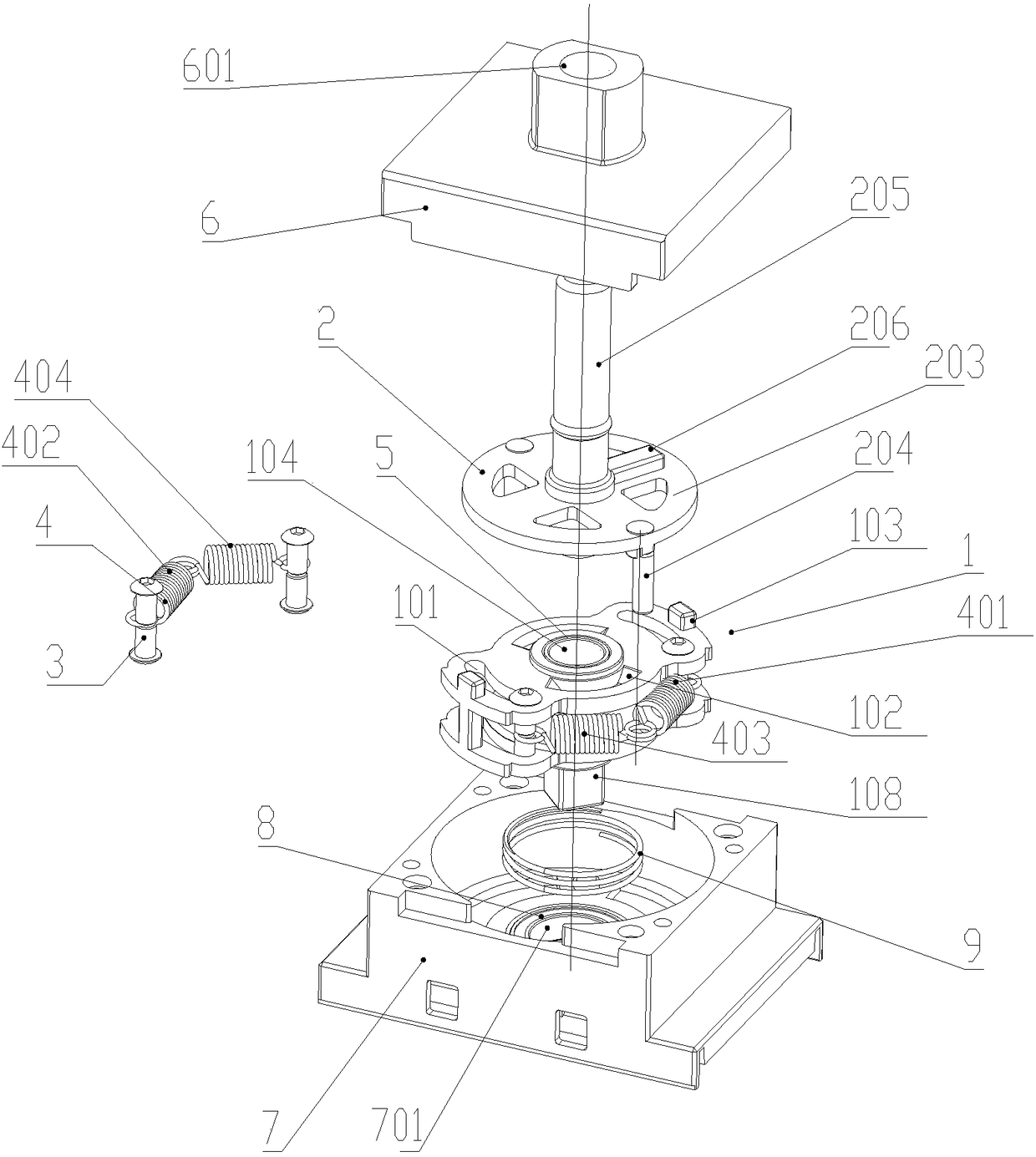

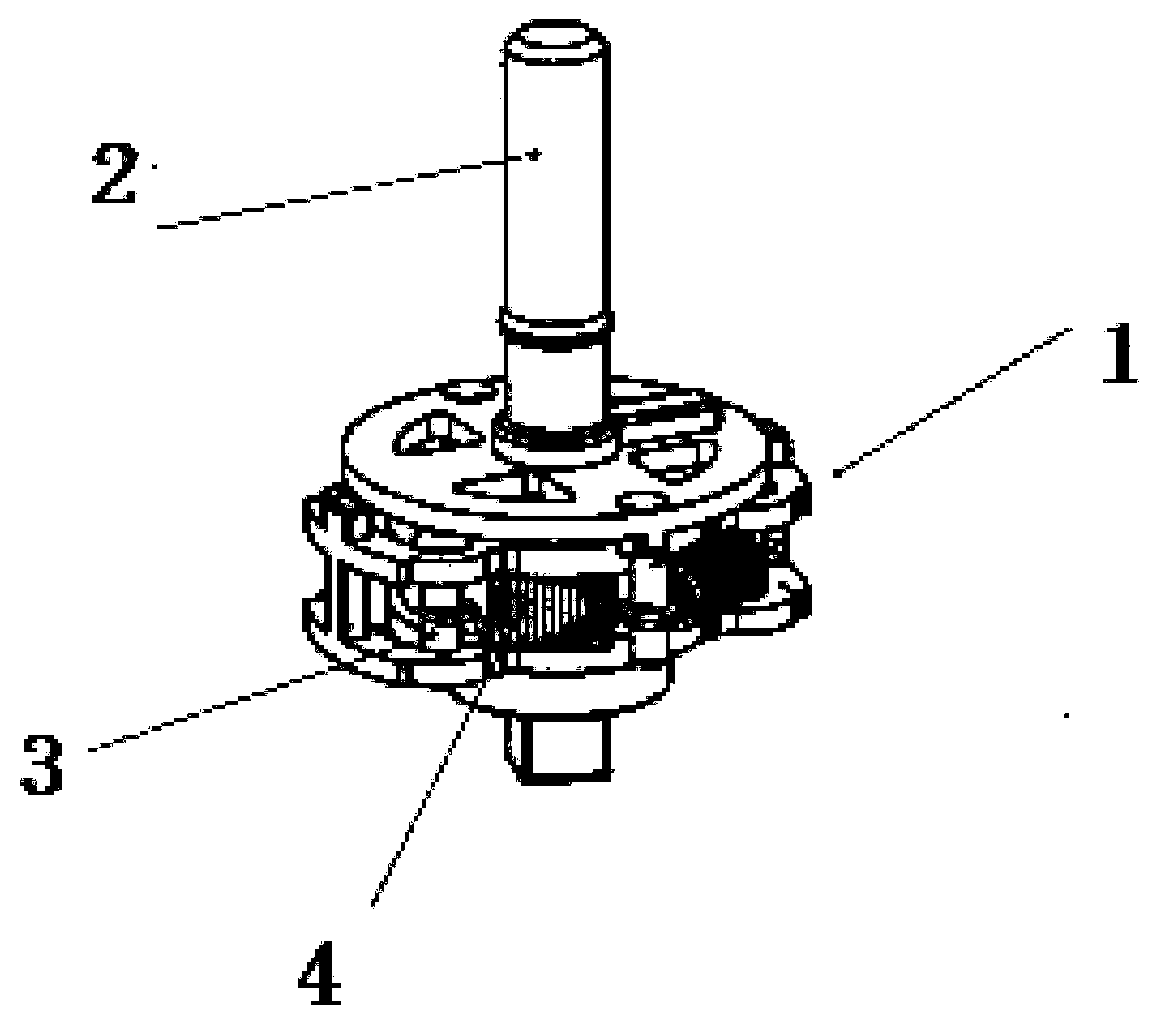

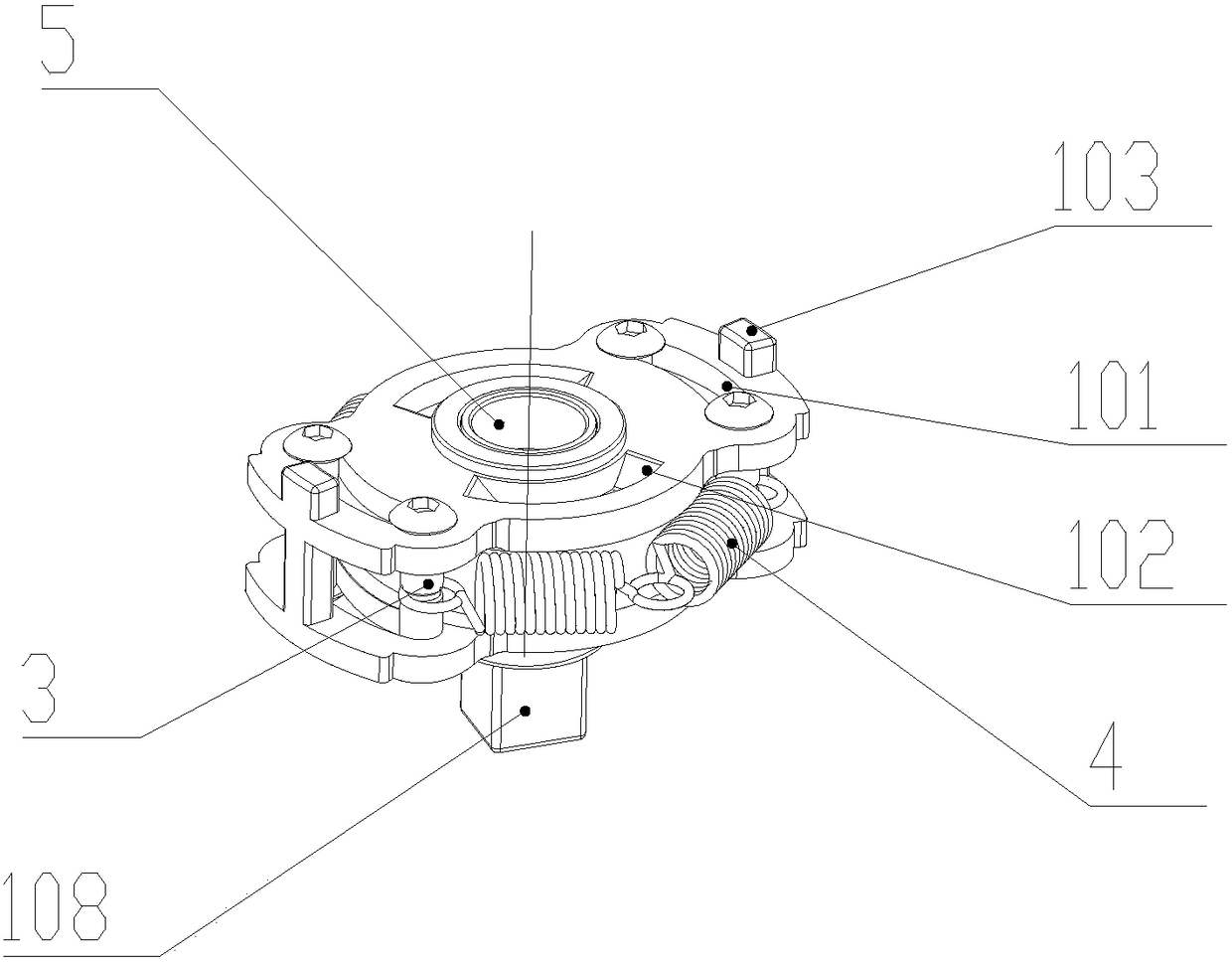

[0026] as attached Figure 2-7 As shown, the energy storage transmission mechanism includes a transmission shaft 1 and a drive shaft 2. The transmission shaft 1 is provided with 2 sliding holes 101, and 4 pairs of locking screws 3 are respectively installed in the preferably arc-shaped long waist hole. The two sliding holes 101 can slide, the upper end surface of the transmission shaft 1 is provided with two track slope grooves 102, and the inner end surface of the drive shaft 2 is provided with two tripping bosses 201 corresponding to the two track slope grooves 102 respectively. There are also two locking bosses 103 on the upper end surface of the shaft 1. The positioning shaft 202 protruding from the driving shaft 2 is installed on the shaft sleeve 5, and the shaft sleeve 5 is installed in the positioning hole 104 on the transmission shaft 1. Two locking buckles Boss 103 is located at the outer side of shaft disc 203 of drive shaft 2, one end of energy storage extension spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com