Isolated heat dissipation structure suitable for charging pile module and heat dissipation method thereof

A heat dissipation structure and isolation technology, applied in the modification of power electronics, electrical equipment structural parts, electrical components, etc., can solve the problem that the heat dissipation structure is easy to damage the internal structure of the charging pile module, etc., to achieve thermal balance, improve product quality Reliability, avoidance of damage by harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

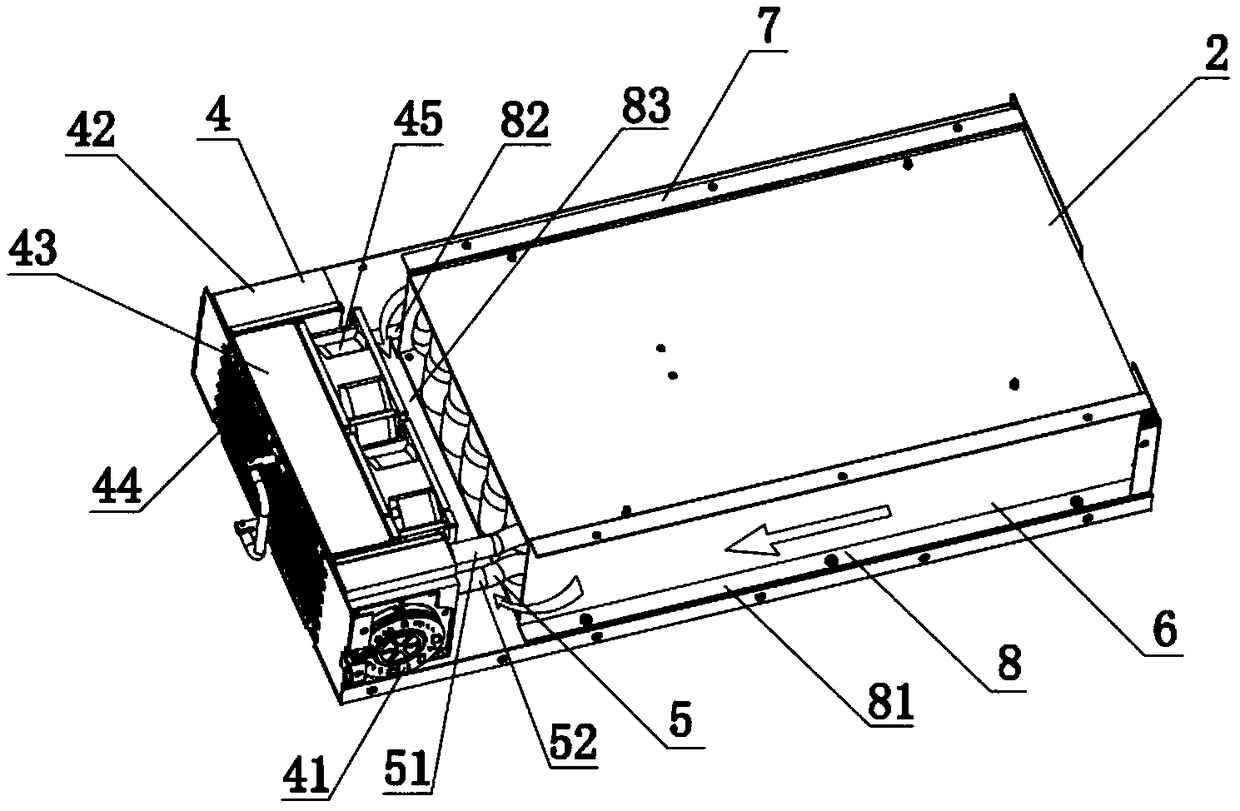

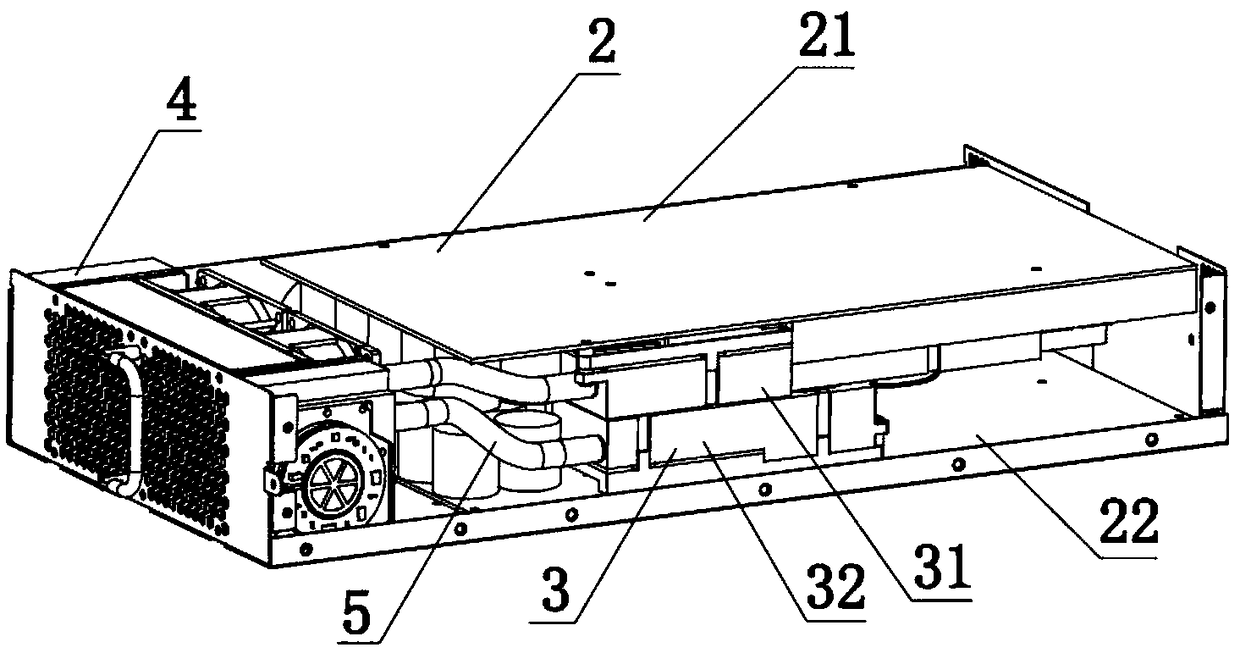

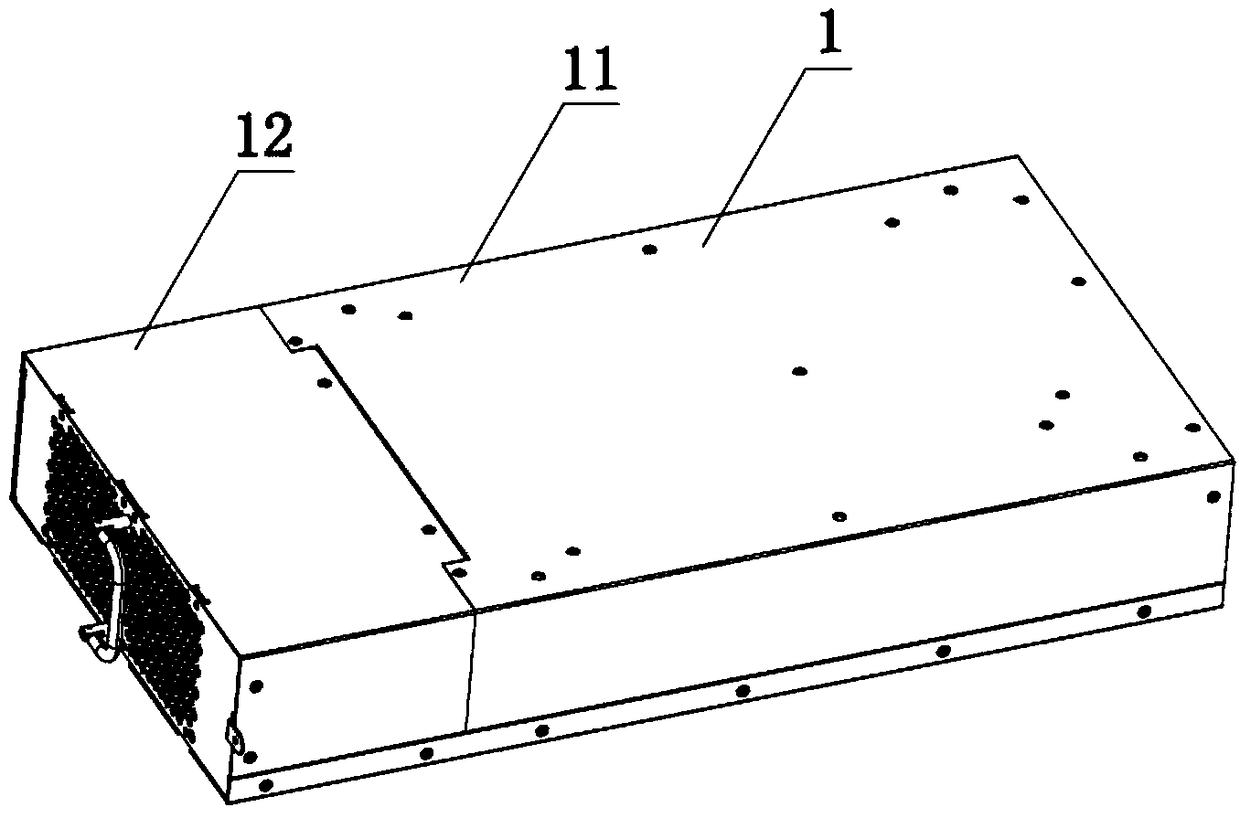

[0022] Such as figure 1 , figure 2 , image 3 As shown, an isolated heat dissipation structure suitable for charging pile modules includes a housing 1, a PCB board module 2, a heat sink module 3 with water channels, a water-cooled and air-cooled heat dissipation module 4, and a coolant pipe 5. One side of the housing 1 is provided with a PCB board module 2, and the other side of the housing 1 is provided with a water-cooled and air-cooled heat dissipation module 4, and one side of the PCB board module 2 is attached to a heat sink module 3 with a water channel The heat sink module 3 with a water channel is connected to the water-cooled and air-cooled heat dissipation module 4 through a coolant pipe 5, and an air channel 8 or a side surface of the housing 1 is formed between the housing 1 and at least one side of the PCB board module 2 The opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com