Systems and methods for authenticating working fluids

A technology for working fluids and mechanical systems, applied in the direction of testing moving fluids/granular solids, material inspection products, fluorescence/phosphorescence, etc., which can solve problems such as expensive and difficult to manufacture markers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

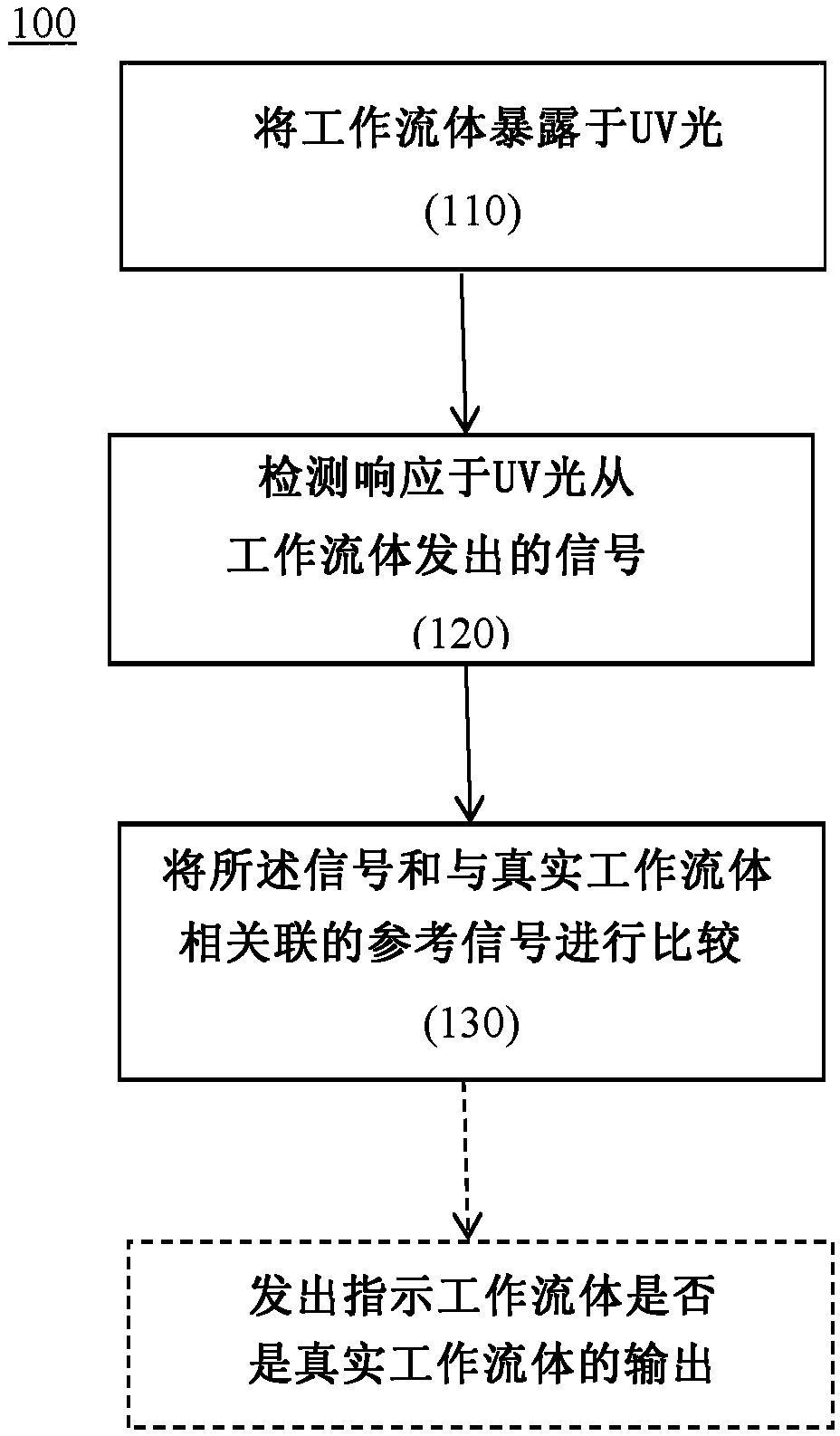

[0037] Example 1. A method for authenticating a working fluid comprising a UV-reactive chemical marker, the method comprising: (a) exposing at least a portion of the working fluid to light having a wavelength in the range of about 10-400 nm , thereby causing the chemical marker to generate a signal; (b) detecting the signal via a sensor system; and (c) comparing the signal to a reference signal associated with an actual working fluid.

Embodiment 2

[0038] Embodiment 2. The method of embodiment 1, further comprising generating an output indicating whether the working fluid is the authentic working fluid.

Embodiment 3

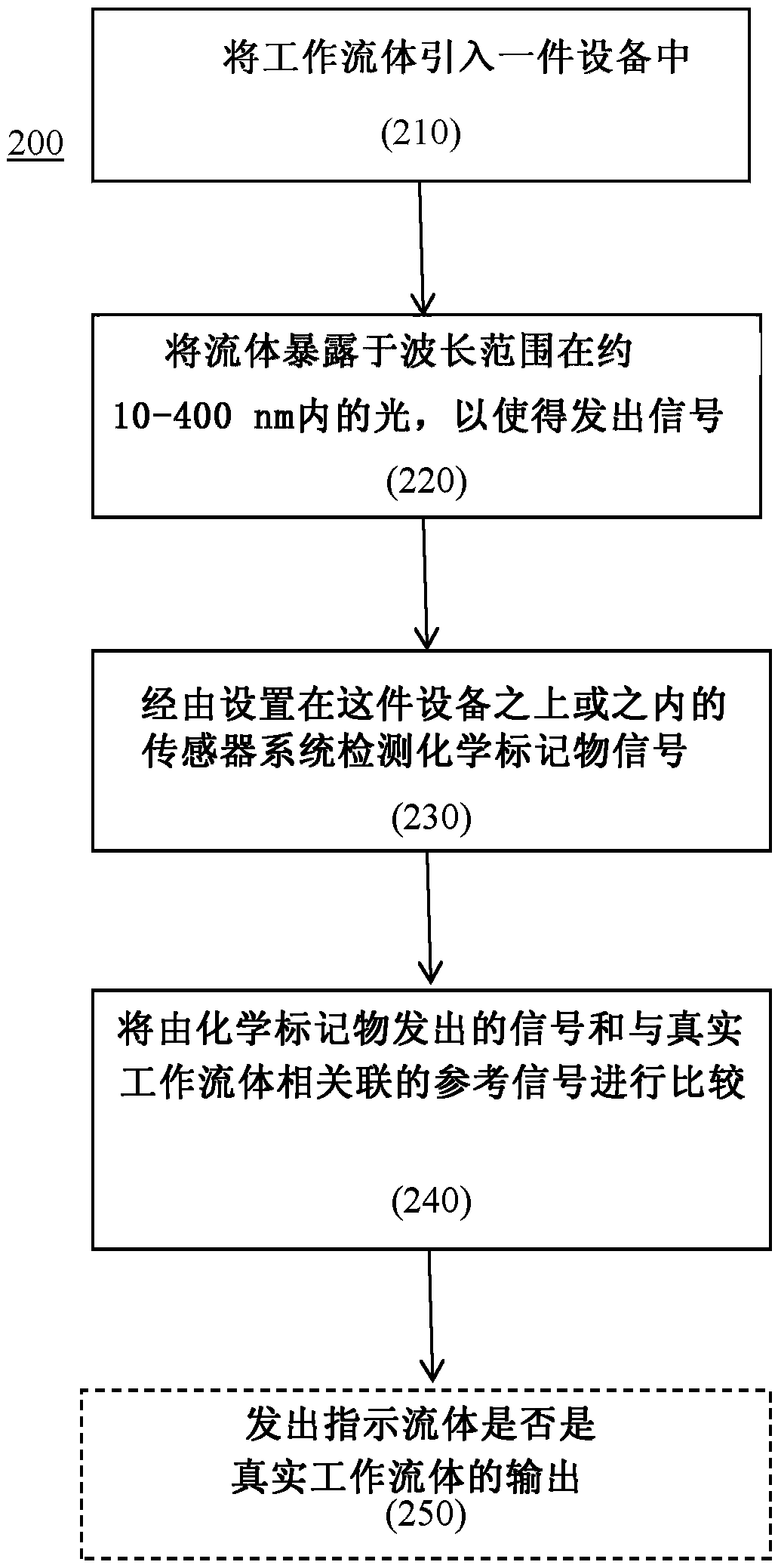

[0039] Embodiment 3. A method for in-situ verification of a working fluid comprising a UV-reactive chemical marker, the method comprising: (a) introducing the working fluid into a mechanical system; (b) introducing the working fluid Exposure of at least a portion of said chemical marker to light having a wavelength in the range of about 10-400 nm, thereby causing said chemical marker to generate a signal; (c) detecting said chemical marker via a sensor system disposed on or within said mechanical system a signal; and (d) comparing said signal generated by said chemical marker to a reference signal associated with an actual working fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com