Poultry glandular stomach-esophagus separation device

The technology of separating device and gland stomach is applied in the field of poultry gland, stomach and esophagus separating device, which can solve the problems of lowering product yield, wasting water resources, and high manual operation cost, so as to reduce operation difficulty, reduce cross-contamination, and save working time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

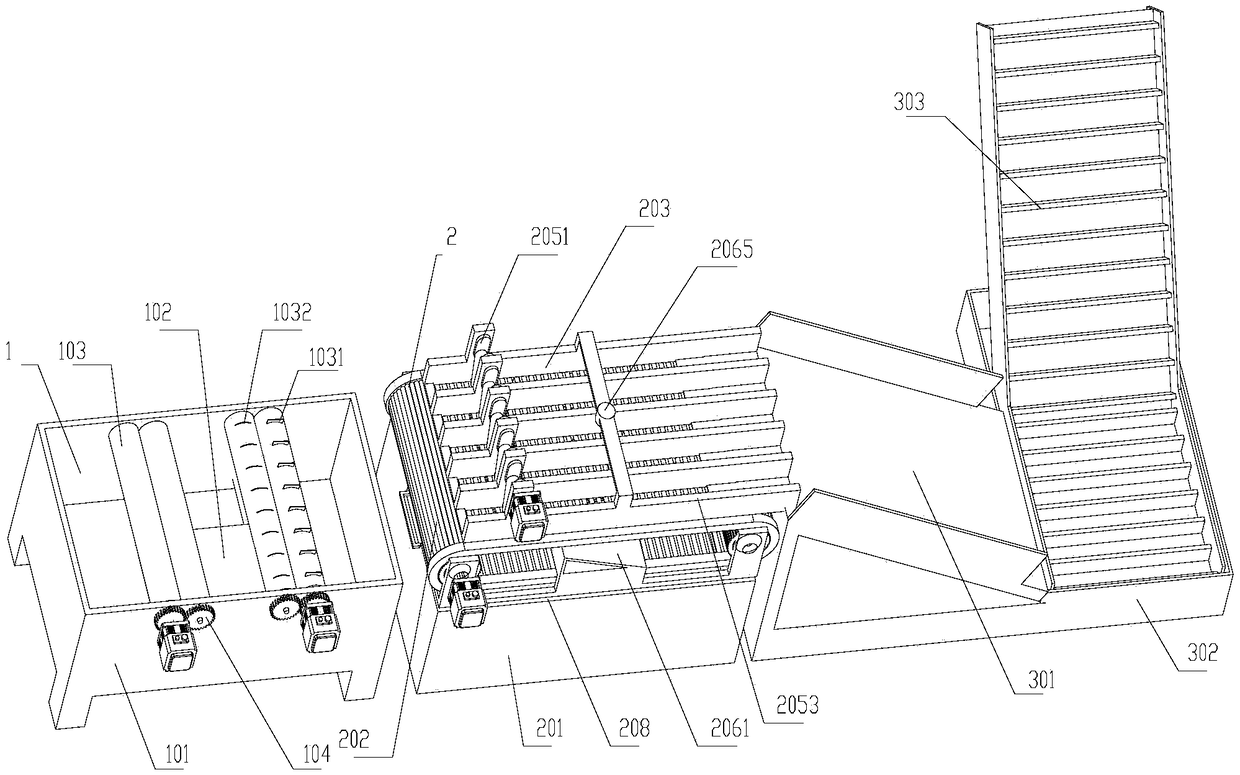

[0039] see Figure 1 to Figure 6, the present invention provides a poultry glandular stomach and esophagus separation device, comprising a glandular stomach and esophagus content cleaning mechanism 1, and a gizzard and glandular gastroesophageal separation mechanism 2 is arranged on one side of the glandular stomach and esophagus content cleaning mechanism 1;

[0040] Glandular stomach and esophageal content cleaning mechanism 1 includes a cleaning pool 101, the inner bottom of the cleaning pool 101 is provided with an ultrasonic vibrating plate 102; the upper part of the cleaning pool 101, lower than the upper edge of the cleaning pool 101, is provided with a clamping roller set and a cutting roller set ;

[0041] Both the clamping roller group and the cutting roller group include two rollers 103 arranged side by side, each roller 103 is provided with a gear 104 on the shaft, and the corresponding gear 104 of the two rollers 103 of the same group meshing with each other, one...

Embodiment 2

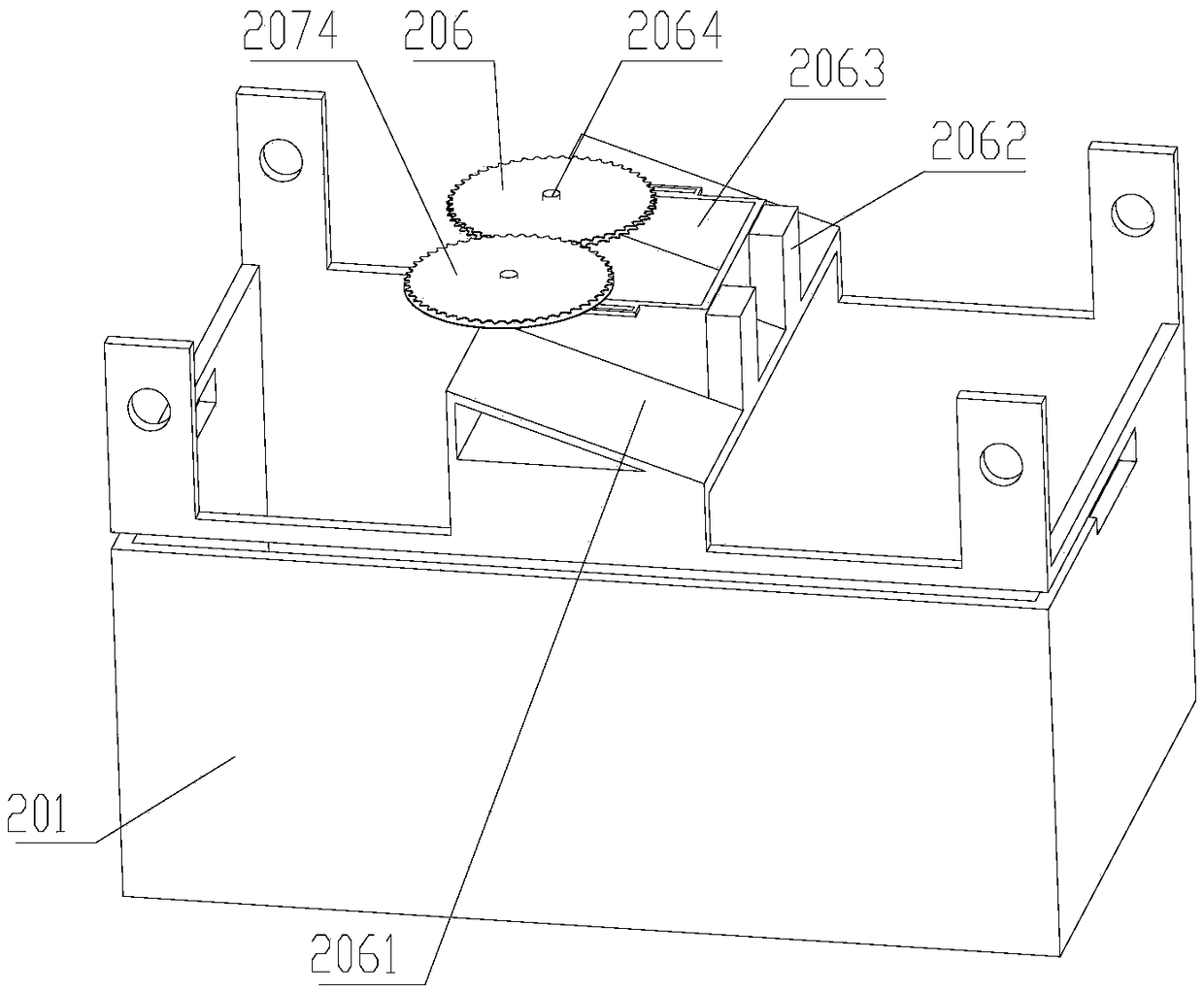

[0062] see Figure 7-Figure 8 On the basis of Embodiment 1, the difference from Embodiment 1 is that an inclined bottom plate 2061 is provided below the cutting mechanism 206, and the bottom plate 2061 is inclined downward. Limiting plates 215 are arranged on the upper and lower edges of the bottom plate 2061 in pairs, respectively. A tray 2063 is arranged in the upper middle of the bottom plate 2061. together, the upper edge and the inner bottom surface of the tray 2063 are inclined downwards, and are parallel to the bottom plate 2061, and the bottom surface of the tray 2063 is provided with a number of leakage holes; one side of the gastroesophageal cleaning pool 201 is provided with a tray shelf 209, the tray shelf The top of 209 is provided with a tray lifting motor, the two sides of the tray lifting motor are respectively provided with a telescopic push rod 214, and the tray shelf 209 and the upper and lower edges of the bottom plate 2061 are respectively provided with a ...

Embodiment 3

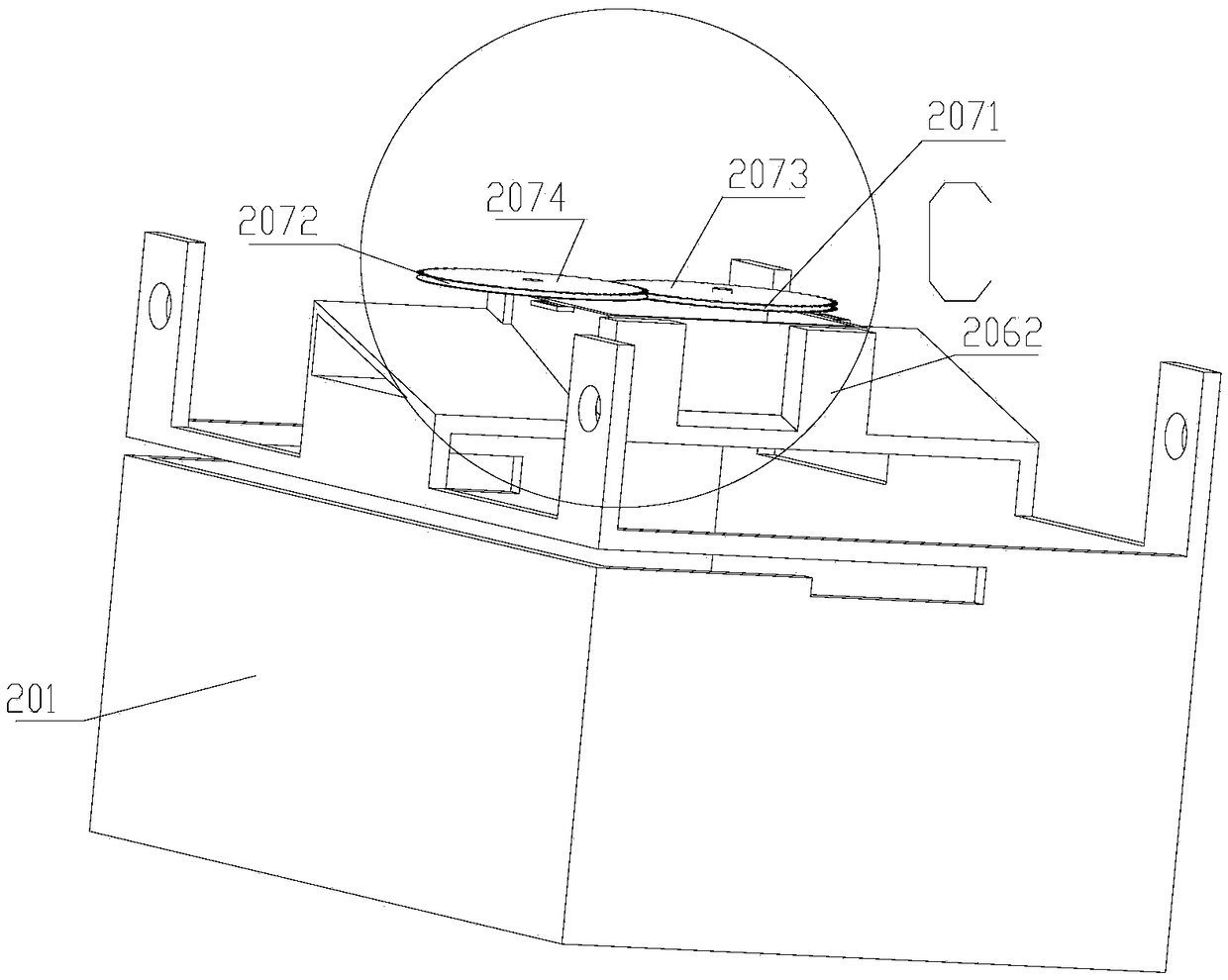

[0069] see Figure 9-Figure 10 , on the basis of Embodiment 1, different from Embodiment 1, a strip-shaped through hole is provided at the bottom of the side wall at the low point of the inclined surface of the tray 2063; two rubber rollers 216 are vertically arranged side by side outside the through hole, two The roller bodies of the rubber rollers 216 fit together; a rubber roller gear is arranged on the rotating shaft of each rubber roller 216, and the rubber roller gears corresponding to the two rubber rollers 216 mesh with each other; one of the rubber roller gears is coaxial with the output shaft of a motor axis;

[0070]The bottom of the bottom plate 2061 is provided with a horizontal panel, and the edge of the panel away from the bottom plate 2061 is provided with a push screw 217; the two ends of the push screw 217 and the panel are provided with four symmetrical fixed blocks on both sides, and the push screw 217 passes through. Pass two of them fixed block and be hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com