A wire feeding structure of an automatic bead stringing machine

A technology of wire feeding structure and beading machine, which is applied in jewelry, clothing, applications, etc., can solve the problems of low beading efficiency, low degree of automation, and low production and processing efficiency, and achieve improved beading efficiency, simple beading operation, and simple alignment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

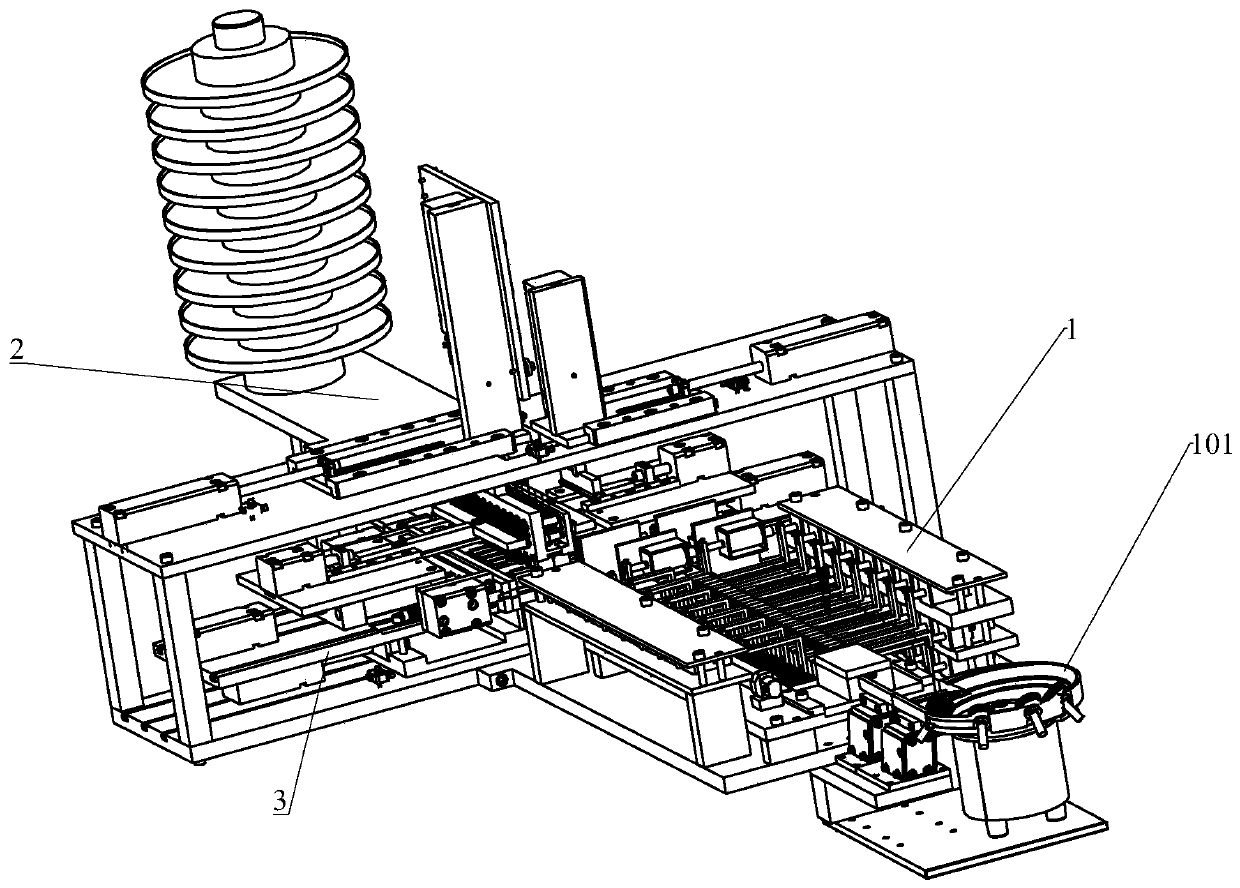

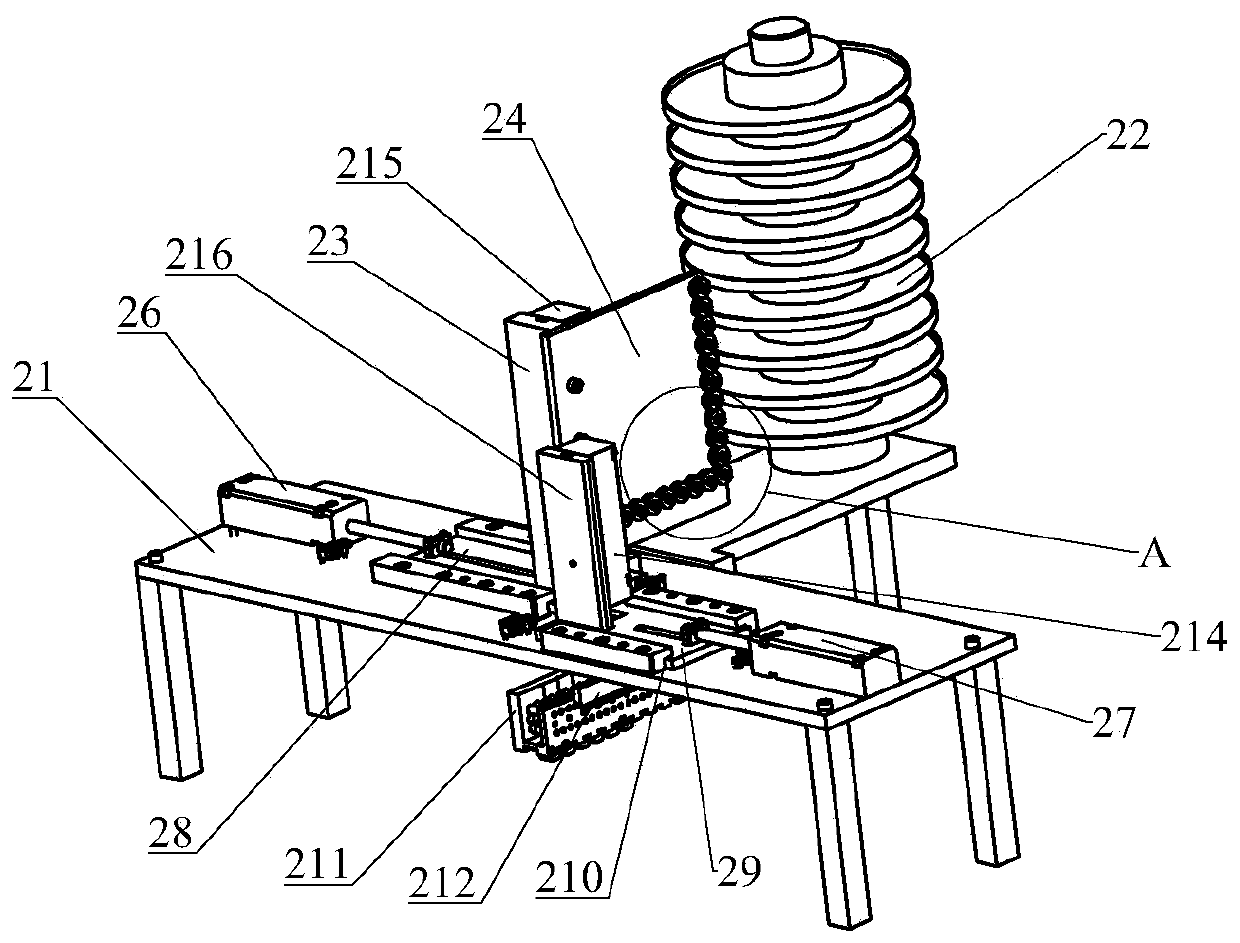

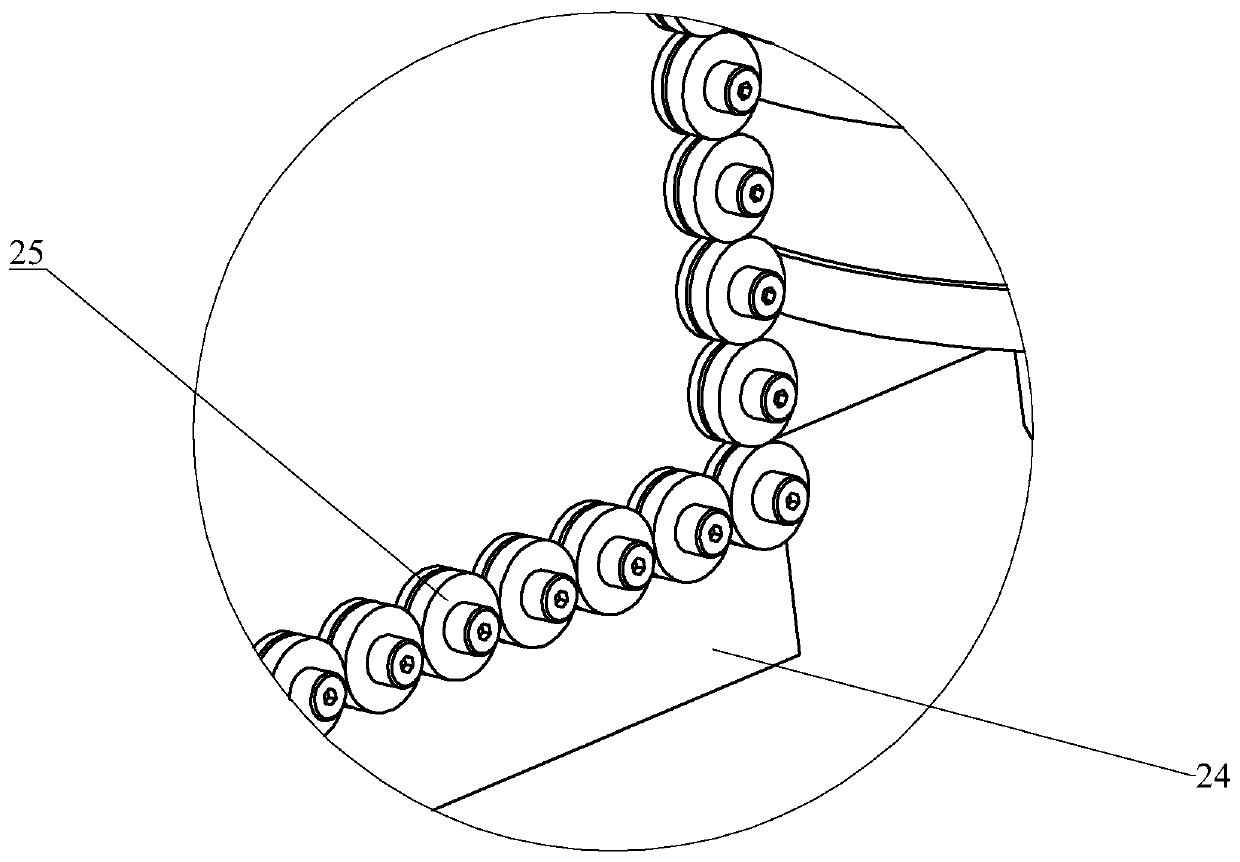

[0027] Such as figure 1 As shown, a fully automatic bead stringing machine includes an arrangement feeding structure 1, a wire feeding structure 2 and a beading structure 3; the arrangement feeding structure 1 includes a vibration queuing and sorting assembly 101, a beading guide assembly, a beading length control assembly, and a beading lateral push assembly , beaded vertical push assembly, next process receiving slot; vibration queuing and sorting assembly 101 includes a vibrating disc host and a delivery slot; the beading guide assembly includes a guide slot; the bead delivery length control assembly includes a length control push electromagnet, a length control connecting rod and a length Control the push slider groove; the beaded horizontal push assembly includes a horizontal push cylinder, and the beaded vertical push assembly includes a longitudinal push cylinder. After a number of scattered beads are arranged in a feeding structure, they are arranged in a row in the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com