Rolling rotor compressor with servo ring hinged blades

A technology of rolling rotor and follower ring, applied in the field of compressors, can solve the problems of difficult to reduce production cost, easy damage of parts and high energy consumption in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

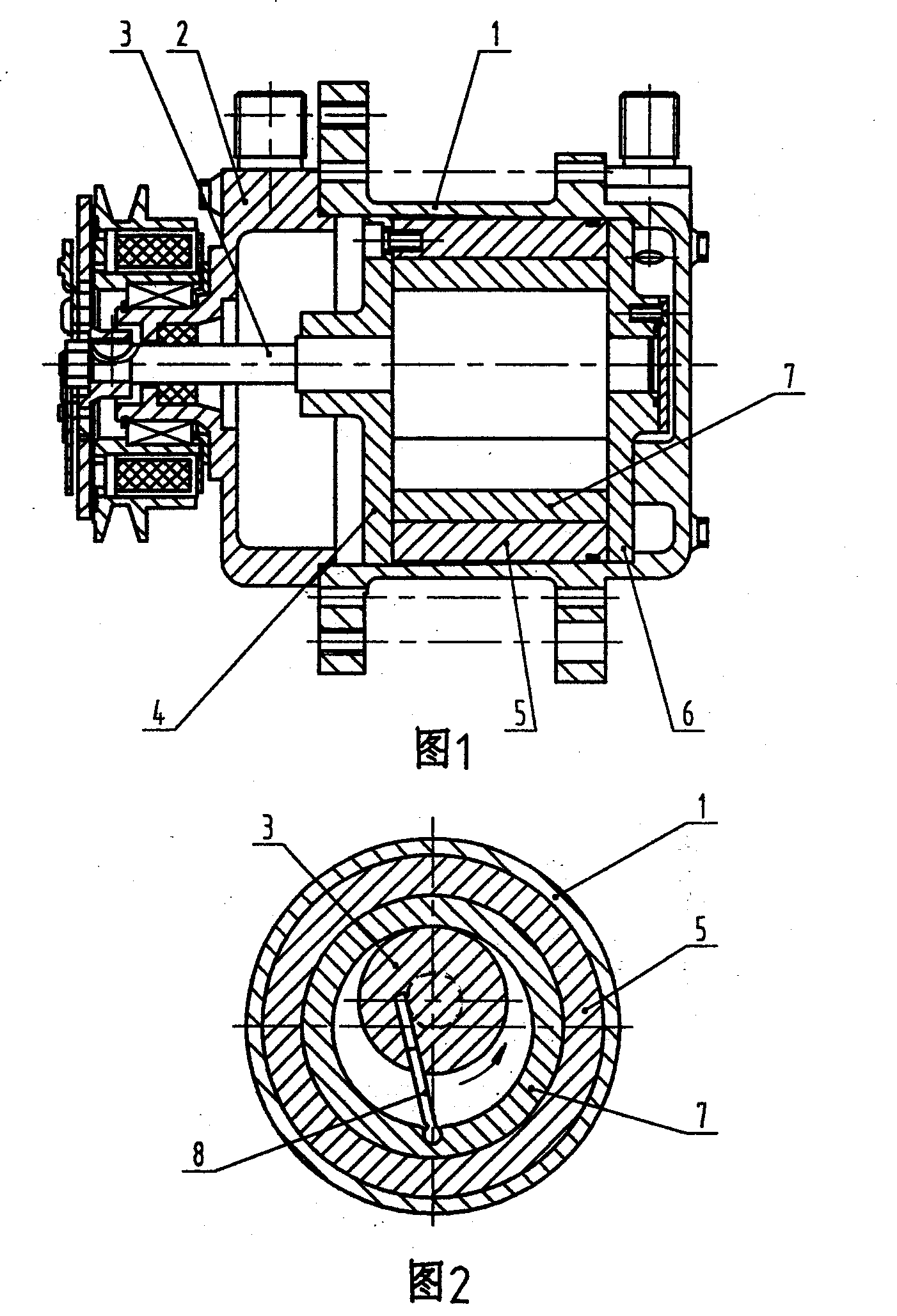

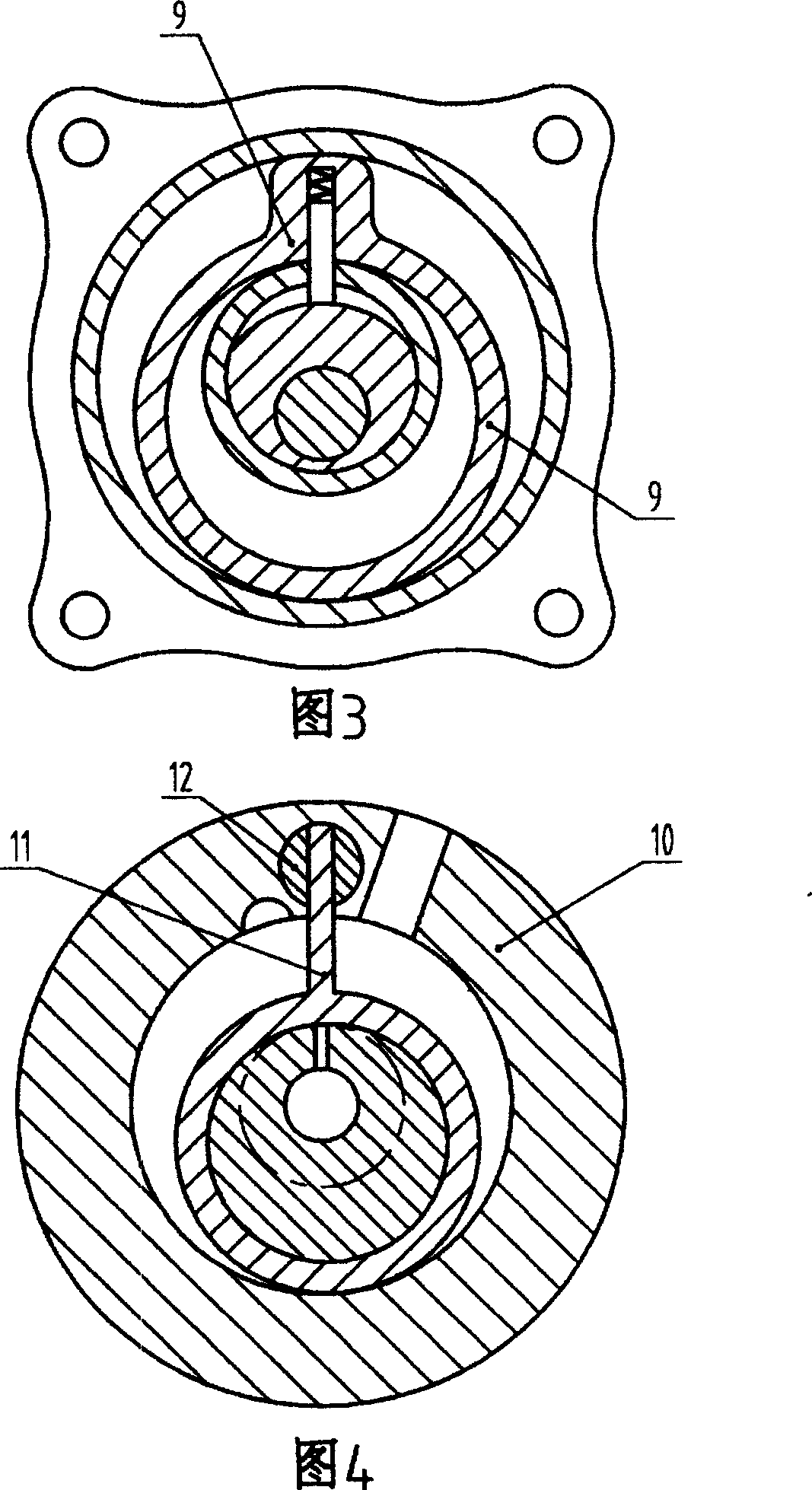

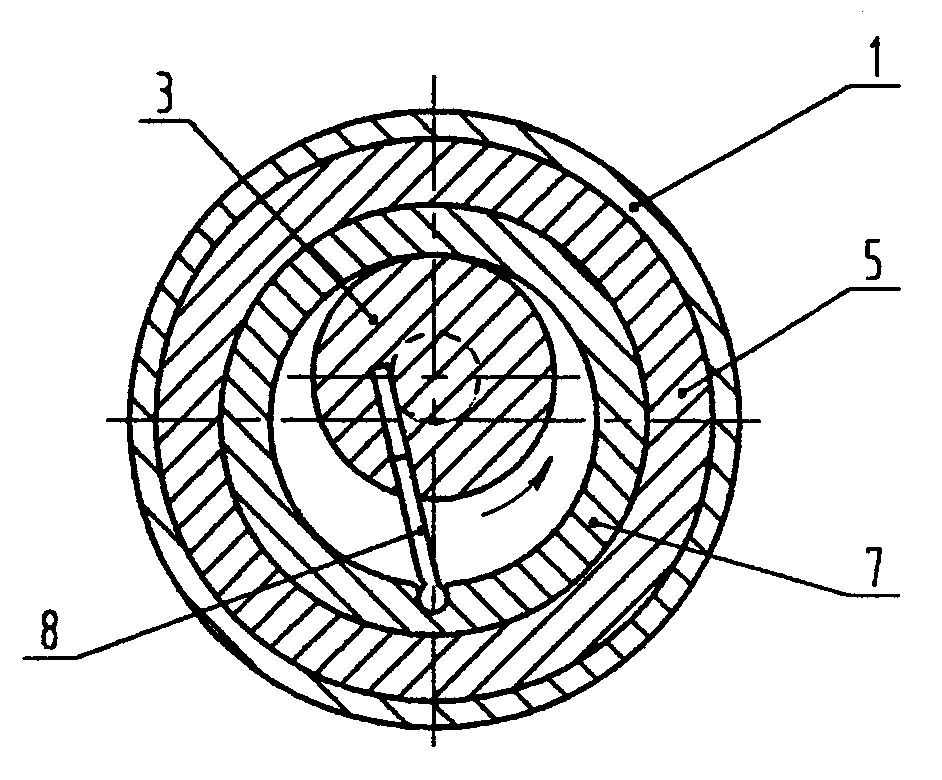

[0011] In the specific implementation process, the casing of the compressor of the present invention is best divided into two parts, the casing 1 and the casing cover 2, as shown in Figure 1. After the cylinder assembly can be fitted in the cavity of the casing 1, Then buckle the shell cover 2 to form the whole machine. The shell 1 and the cover 2 can be made of lightweight materials such as aluminum alloy. The drive shaft 3 is a concentric shaft with all shaft steps. The projecting holes of the drive shaft 3 on the shell cover 2 and the bearing housing holes on the front cylinder head 4 and the rear cylinder head 6 can be connected between the drive shaft 3 and the cylinder barrel. 5 After the eccentric distance of the axis line of the inner cavity (actually from the inner circular cavity of the follower ring 7) is determined, one positioning and boring is performed. Because the cylinder tube 5 of the compressor of the present invention does not need to be provided with a longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com