Light-emitting diode (LED) power supply driving circuit

A technology of LED power supply and driving circuit, which is applied in the direction of electric lamp circuit layout, electric light source, light source, etc., can solve the problems of no overload prevention, strong anti-interference ability, vibration noise, etc., and achieve no vibration noise, strong anti-interference ability, and work Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

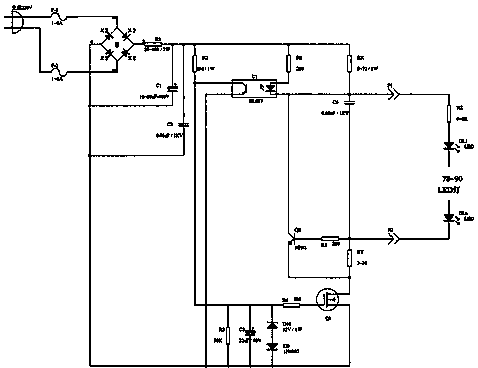

Image

Examples

Embodiment Construction

[0016] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0017] refer to figure 1 , an embodiment of a LED power drive circuit of the present invention is proposed. This LED power drive circuit is used to connect with an external alternating current and control an LED lamp. It includes a rectifier bridge W for converting alternating current into direct current and for outputting constant Current and driving power module for driving LED lights, optocoupler U1 for isolation, feedback or correction to output constant current, overload protection module for over-current or over-voltage protection of LED lights. The photocoupler U1 includes a light emitter and a light receiver, one end of the light emitter is connected to the current output end of the rectifier bridge W, and the other end is respectively connected to an electrode of the overload protection module and the LED lam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com