A glue removal and cleaning equipment for producing sanitary napkins

A technology for cleaning equipment and sanitary napkins, applied in sanitary napkins, cleaning devices, applications, etc., can solve problems such as inability to scrape, incapable of viscose grinding, inconvenient for debris collection, etc., and achieve the effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

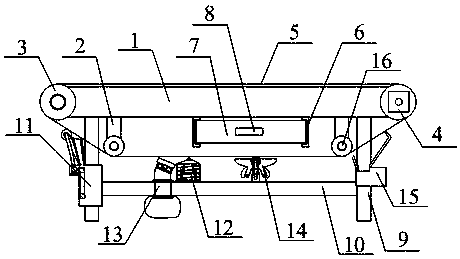

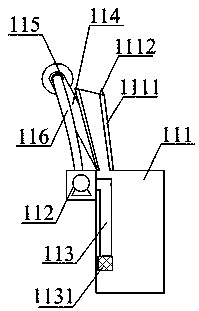

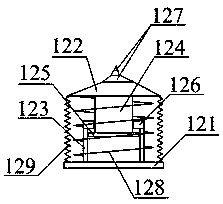

[0042] as attached figure 1 to attach Figure 6 shown

[0043] The present invention provides a glue removal and cleaning device for producing sanitary napkins, comprising a conveying table 1, an auxiliary support 2, a conveying roller 3, a driving motor 4, a conveying belt 5, a U-shaped frame 6, a tool storage bucket 7, a handle 8, Supporting legs 9, fixed horizontal plate 10, surface circulating humidification frame structure 11, buffer guide structure with surface glue removal frame 12, viscose debris collection and storage frame structure 13, secondary glue removal grinding frame structure 14, with flour dust Debris scraping frame structure 15 and auxiliary guide rollers 16, the auxiliary brackets 2 are longitudinally welded at the four corners of the middle and lower part of the conveying platform 1; the conveying rollers 3 are axially connected to the left and right sides of the conveying platform 1; The drive motor 4 bolts described above are installed on the right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com