Cavity-free composite heat-insulation thermal-break bridge structure and construction method

A composite thermal insulation and structural body technology, applied in thermal insulation, building components, building structures, etc., can solve the problems of hidden fire hazards, increased cost of building exterior wall insulation, etc., and achieve the effect of meeting fire protection requirements and solving thermal bridge phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

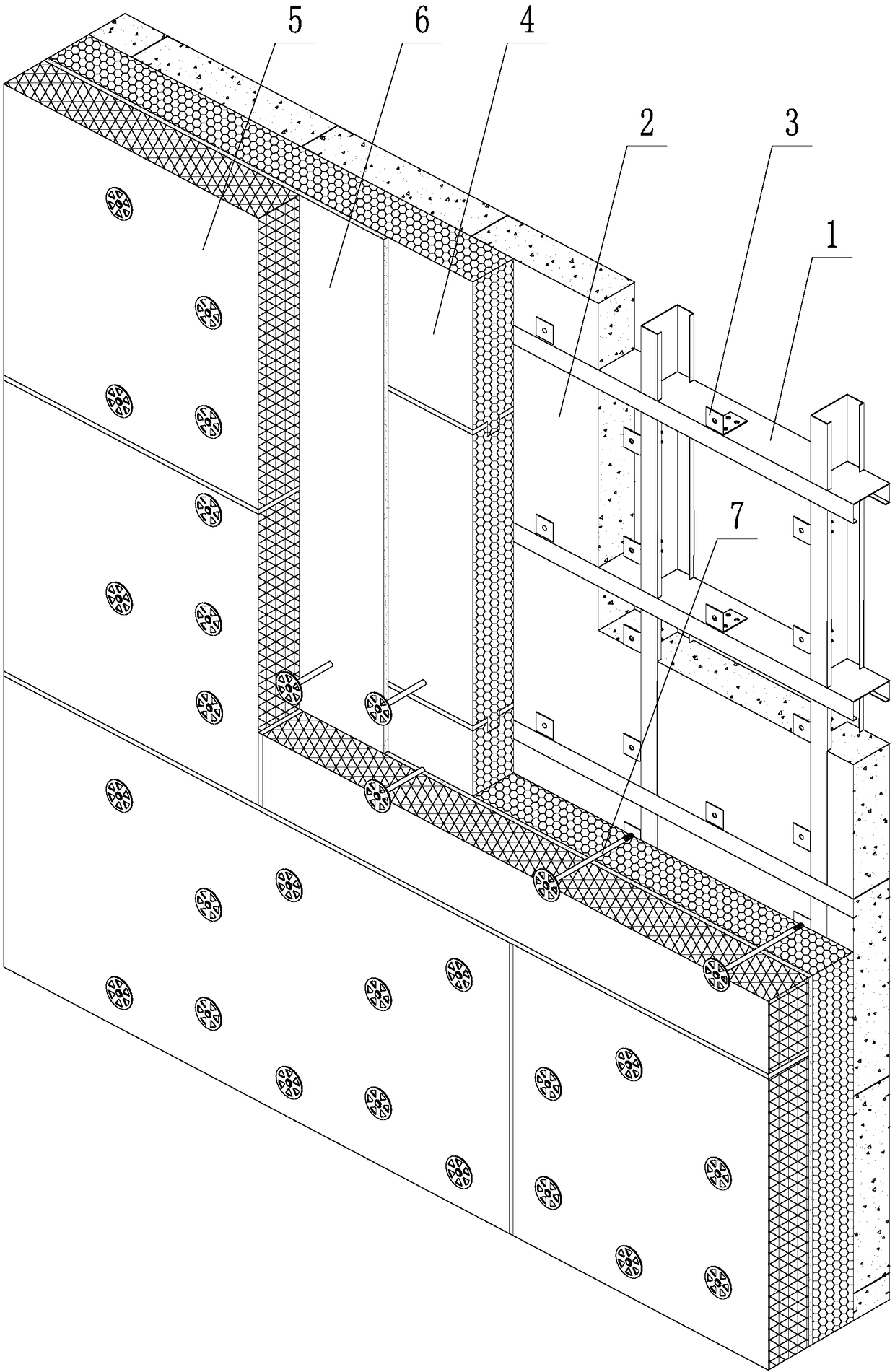

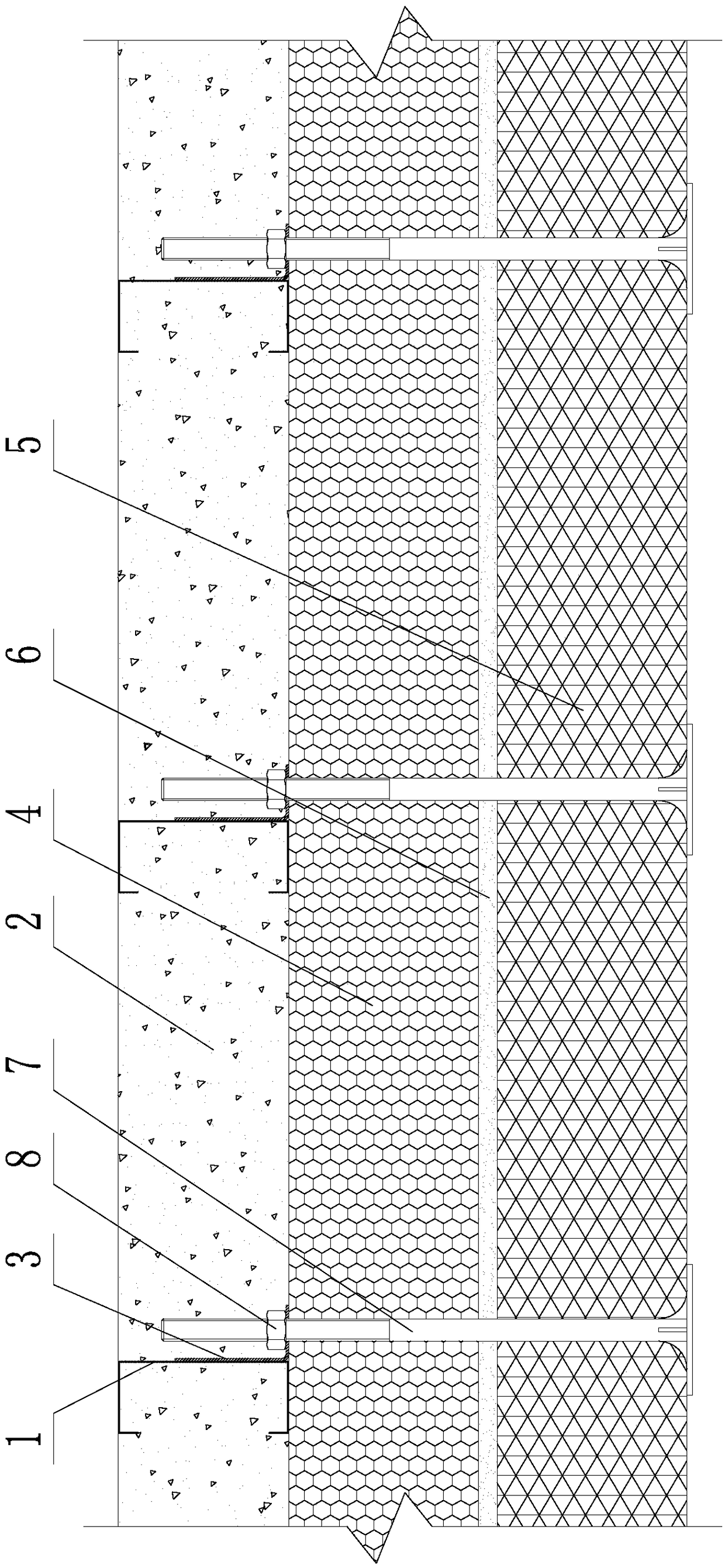

[0028] Such as figure 1 , 2 As shown, a cavity-free composite thermal insulation bridge structure includes an inner structural layer, an intermediate thermal insulation layer and an outer protective layer; the inner structural layer includes a light steel skeleton 1, a lightweight concrete wall 2 and an adapter frame 3. Both the light steel frame 1 and the adapter frame 3 are poured in the lightweight concrete wall 2, and the adapter frame 3 is fixedly connected to the light steel frame 1; the middle insulation layer includes B1 / B2 grade insulation materials 4, B1 The / B2 grade thermal insulation material 4 is a block plate, and the middle thermal insulation layer is composed of several pieces of B1 / B2 grade thermal insulation material 4; 5 pieces of non-combustible materials are spliced together; an adhesive layer 6 is provided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com