Bridge-cutoff cornice structure applied to ultra-low energy consumption building

It is a technology of energy consumption and construction, which is applied in the direction of building components, building structures, buildings, etc. It can solve the problems of life mismatch, falling off of the main body of the building, and reduce the overall energy saving effect of ultra-low energy consumption buildings, so as to improve the overall energy saving effect and reduce The hidden danger of falling off and the effect of avoiding thermal bridge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

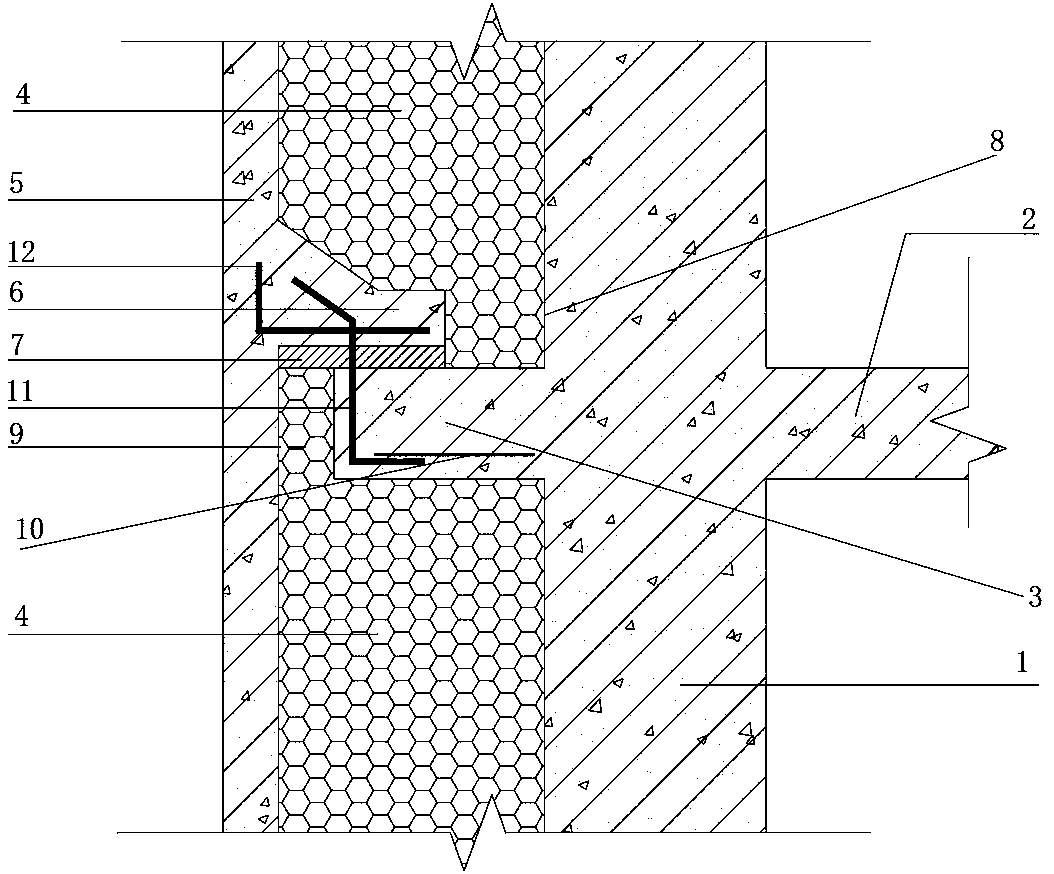

[0011] See figure 1 As shown, the present invention provides a broken bridge overhanging structure applied to an ultra-low energy building, including a reinforced concrete wall 1, a reinforced concrete floor located in the middle of the reinforced concrete wall 2, located outside the reinforced concrete wall and a reinforced concrete floor The opposite wall canopy 3, the thermal insulation material layer 4 on the outer side of the reinforced concrete wall, the reinforced concrete structure layer 5 on the outer side of the thermal insulation material layer, the inner side of the reinforced concrete structure layer is provided with a structural layer reverse canopy 6, the structural layer The reverse cantilever is located above the wall cantilever and overlaps with the wall cantilever; the structural layer reverse cantilever and the wall cantilever are separated by a high-efficiency insulation board 7; the thickness of the thermal insulation material layer is greater than the wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com