A fast-assembled lightweight box-panel house

A light-weight, box-based technology, applied in the direction of building types, buildings, small buildings, etc., can solve the problems of increasing the difficulty of transportation management, reducing the waterproof performance of box and board houses, and short service life, so as to reduce transportation and management. Difficulty, high assembly and disassembly efficiency, and the effect of improving disassembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

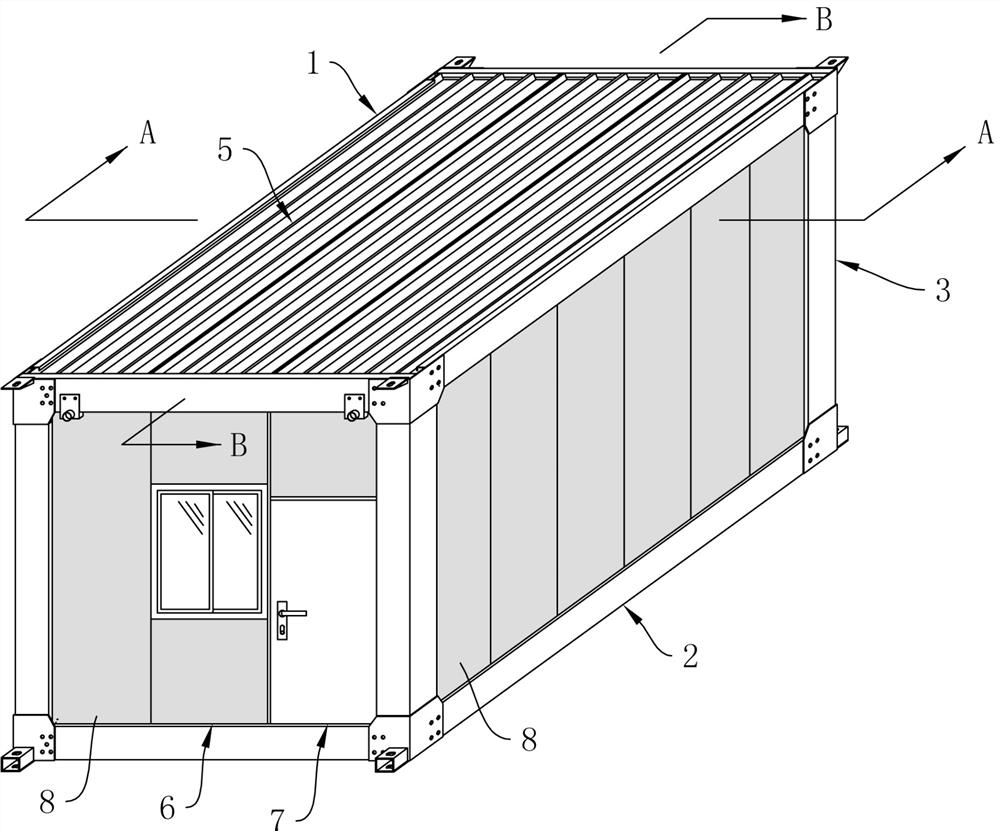

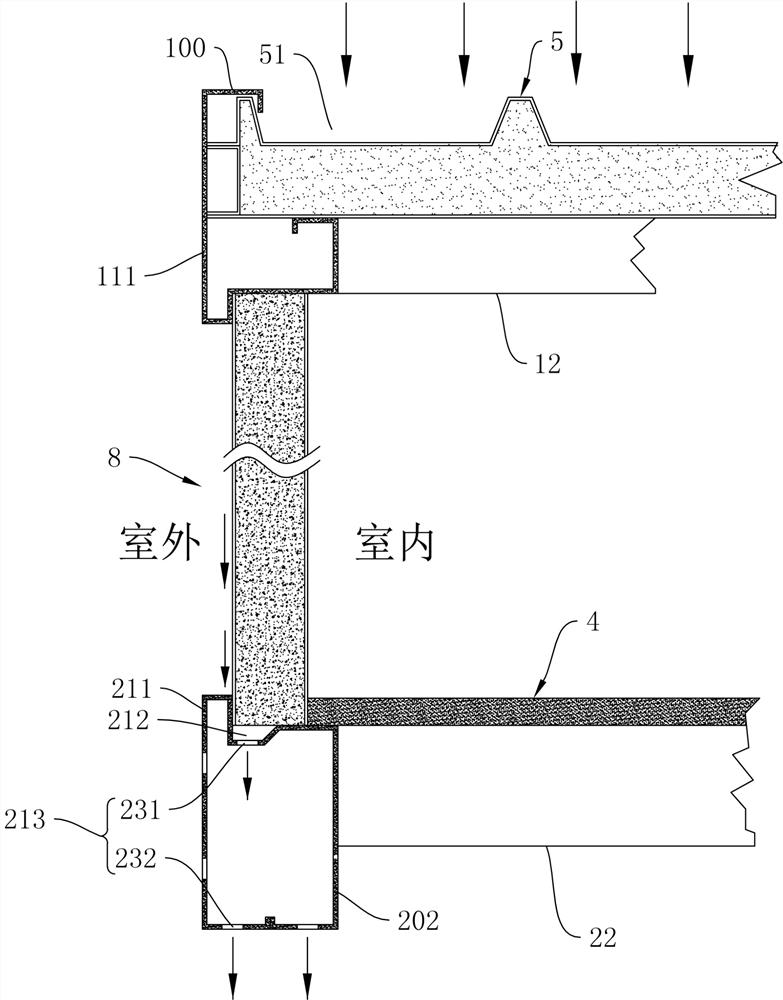

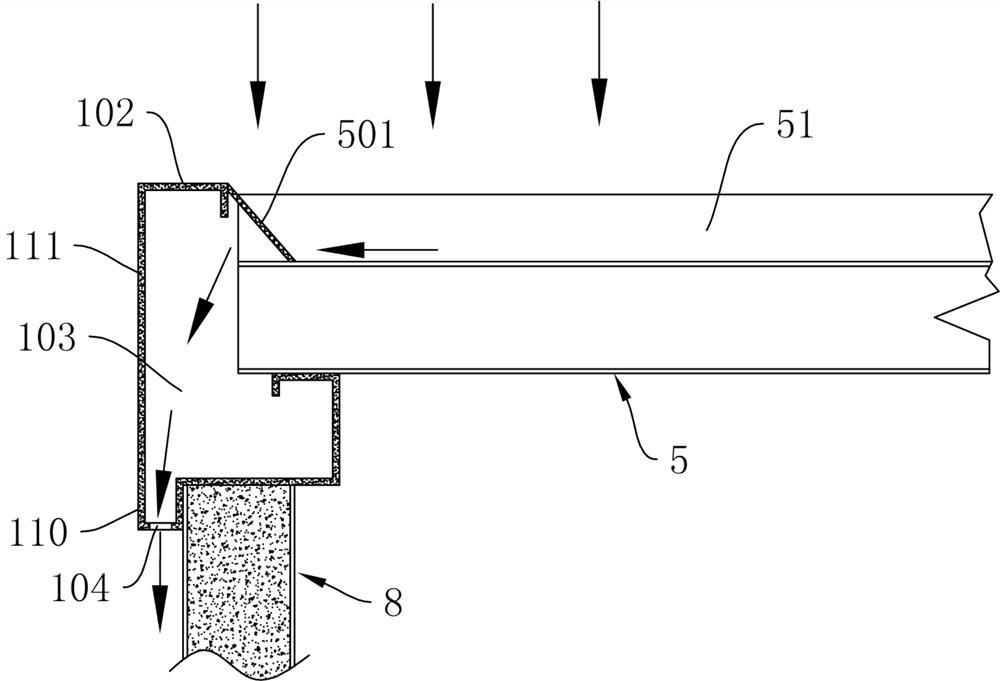

[0033] Such as figure 1 and figure 2 As shown, a light-weight box board house for rapid assembly according to the present invention includes a top frame 1, a bottom frame 2, several columns 3, a floor 4, floor tiles 5, window wall panels 6, and door body wall panels. 7. A number of wall panels 8, wherein, such as Figure 4 , Figure 6 and Figure 7 As shown, the top frame 1 includes a top frame beam 11 and several top purlins 12. The top frame beam 11 is enclosed to form an upper installation cavity 10, and several The upper hanging hole 101, the two ends of the top purlin 12 are respectively arranged on the upper hanging piece 121, each top purlin 12 is respectively arranged in the upper installation cavity 10, and the upper hanging piece 121 at the two ends of the top purlin 12 are respectively hung Installed on the corresponding upper hanging hole 101; if Figure 4 , Figure 8 and Figure 9 As shown, the underframe 2 includes a bottom frame beam 21 and several layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com