Cleaning method of extractor hood, extractor hood controller and extractor hood

A technology of range hood and thermostat, which is applied in the direction of removing range hood, application, household stove, etc., can solve the problems of poor cleaning effect, difficulty in cleaning range hood and oil pollution, low cleaning efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

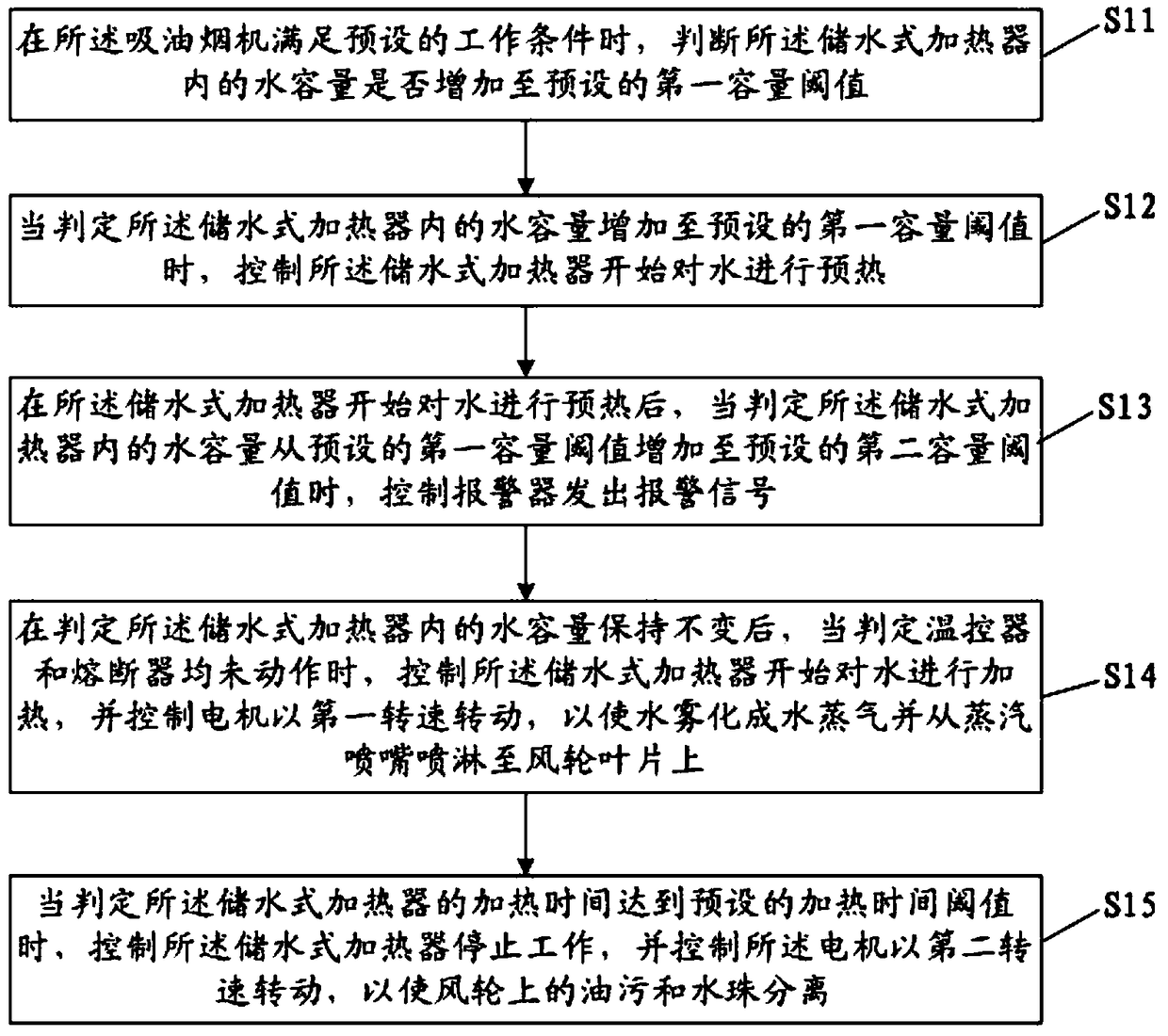

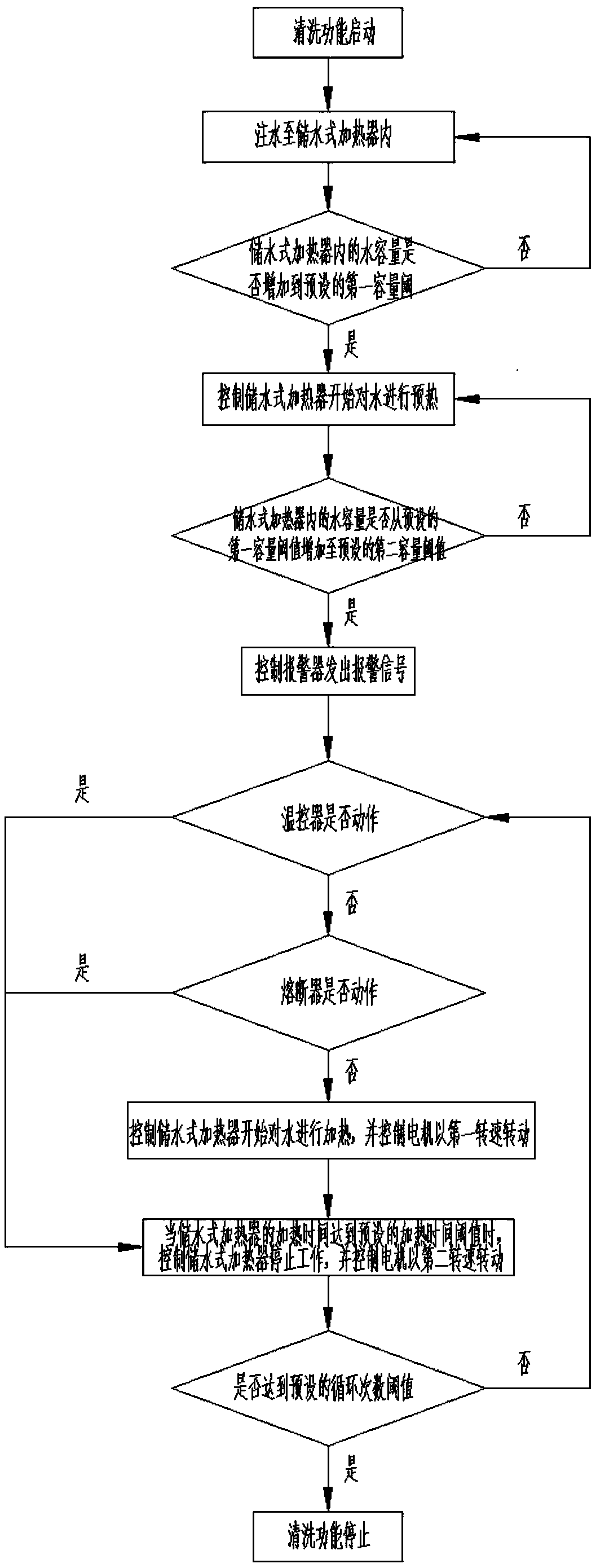

[0050] combine figure 1 and figure 2 As shown, a cleaning method for a range hood according to a preferred embodiment of the present invention includes:

[0051] S11, when the range hood satisfies a preset working condition, judge whether the water capacity in the water storage heater has increased to a preset first capacity threshold;

[0052] S12. When it is determined that the water capacity in the water storage heater has increased to a preset first capacity threshold, control the water storage heater to start preheating the water;

[0053] S13. After the water storage heater starts to preheat the water, when it is determined that the water capacity in the water storage heater increases from a preset first capacity threshold to a preset second capacity threshold, Controlling the alarm to send out an alarm signal; wherein, the alarm signal includes a reminder signal for reminding the user to stop water injection;

[0054] S14. After determining that the water capacity i...

Embodiment 2

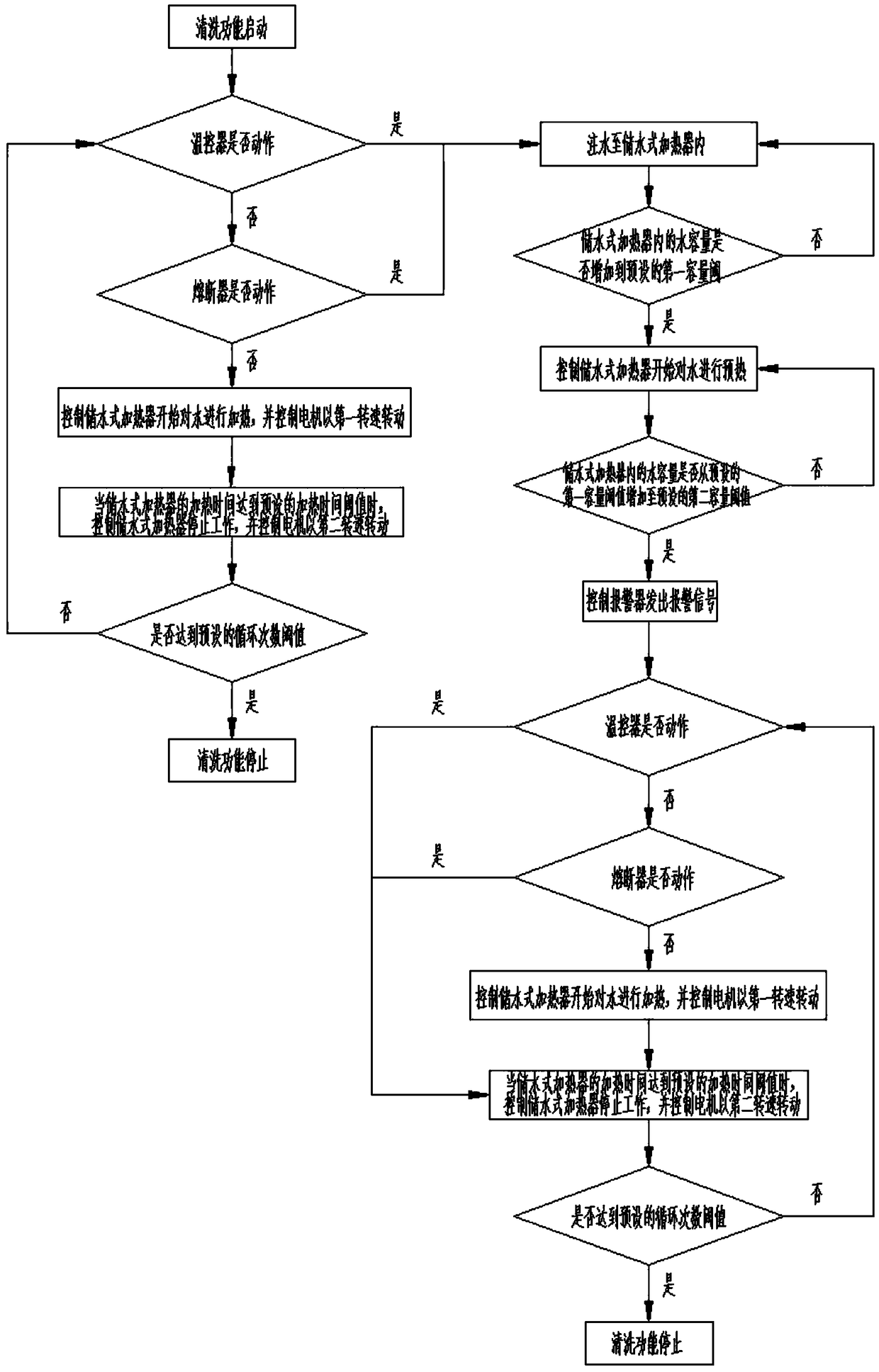

[0075] combine figure 1 and image 3 As shown, the difference between the cleaning method for the range hood in this embodiment and the first embodiment is that when the range hood meets the preset working conditions, it is judged that the water storage heater Whether the water capacity inside increases to the preset first capacity threshold is specifically:

[0076] When the range hood meets the start-up condition of the cleaning function and the temperature controller on the range hood operates, it is determined whether the water capacity in the water storage heater has increased to a preset first capacity threshold.

[0077] In the embodiment of the present invention, after starting the cleaning function of the range hood, when the temperature controller on the range hood operates, because the temperature of the range hood is too high at this time, it may have been performed before. After the cleaning work of the range hood, it is not appropriate to control the water stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com