A method for measuring and calibrating the missed distance of laser target projectiles based on pulse shadow imaging

A calibration method, a technology of missing target amount, applied in the direction of measuring device, mechanical gap measurement, using optical device, etc., can solve the problems of response consistency difference, projectile velocity error, projectile flight distance, etc., to achieve small size and high precision. , to ensure the effect of clear imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

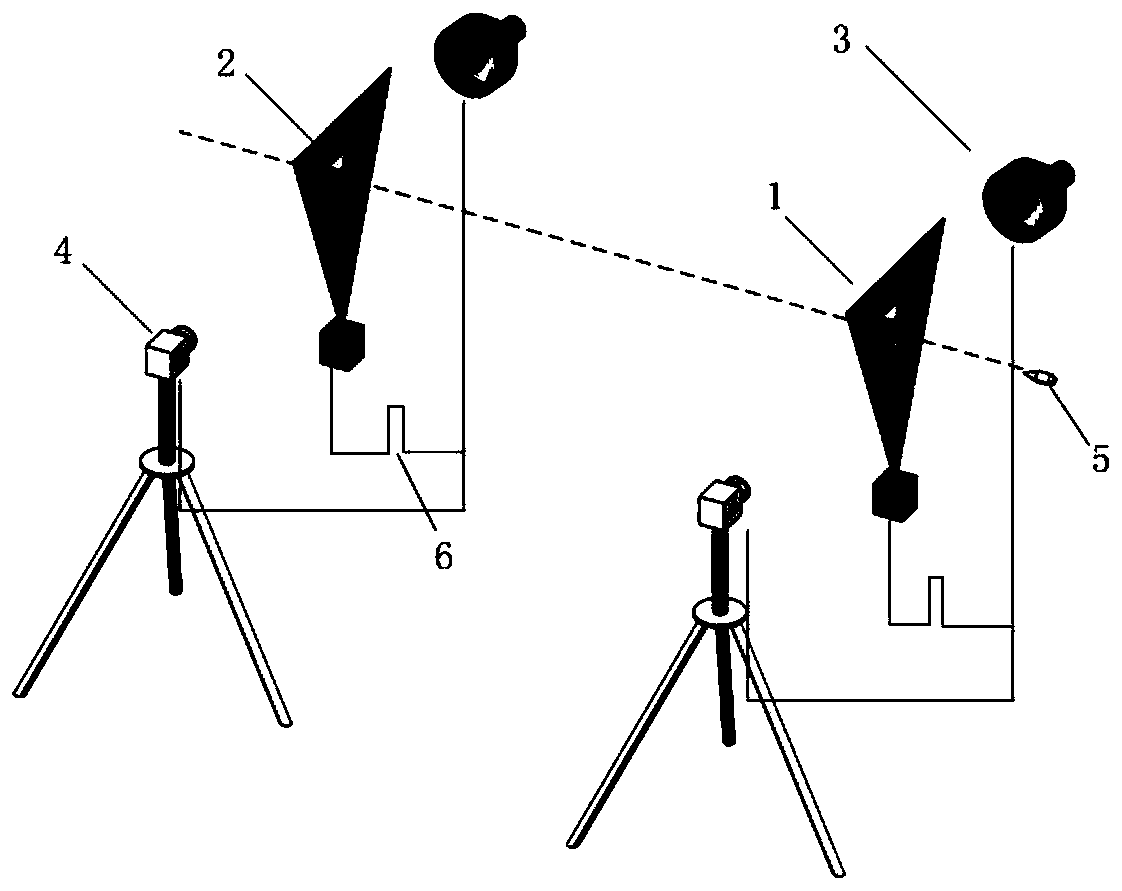

[0026] A method for measuring and calibrating the amount of laser target projectiles missing the target based on pulse shadow imaging of the present invention is realized by using the start target subsystem and the stop target subsystem built, such as figure 1 As shown, both subsystems include four key parts: laser target 1, glass linear scale 2, pulsed parallel light source 3, and high-resolution camera 4.

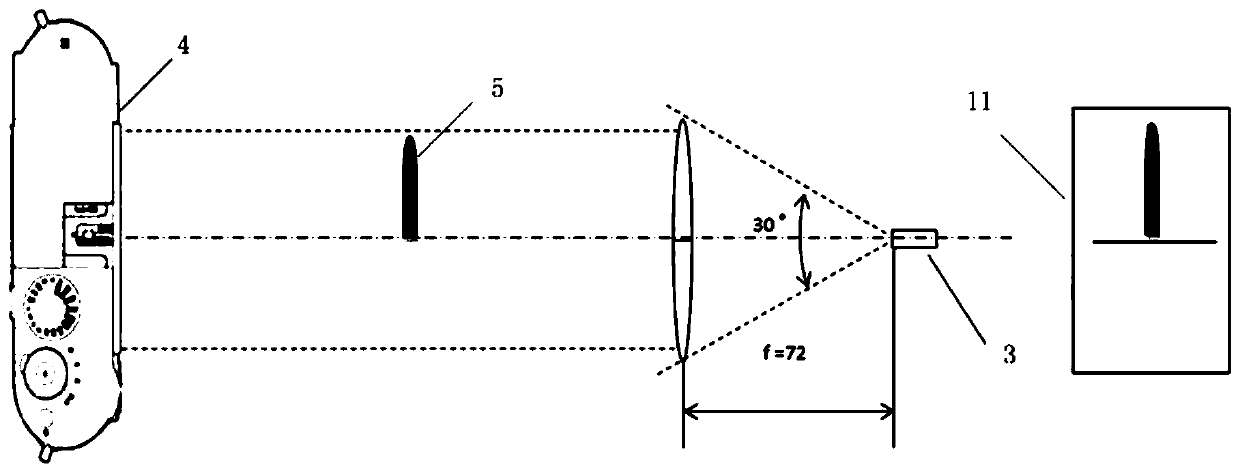

[0027] A pulsed parallel light source 3 and a high-resolution camera 4 are respectively set up on both sides of the laser light curtain of the laser target 1; as shown in FIG. format, forming bright areas on the image sensor.

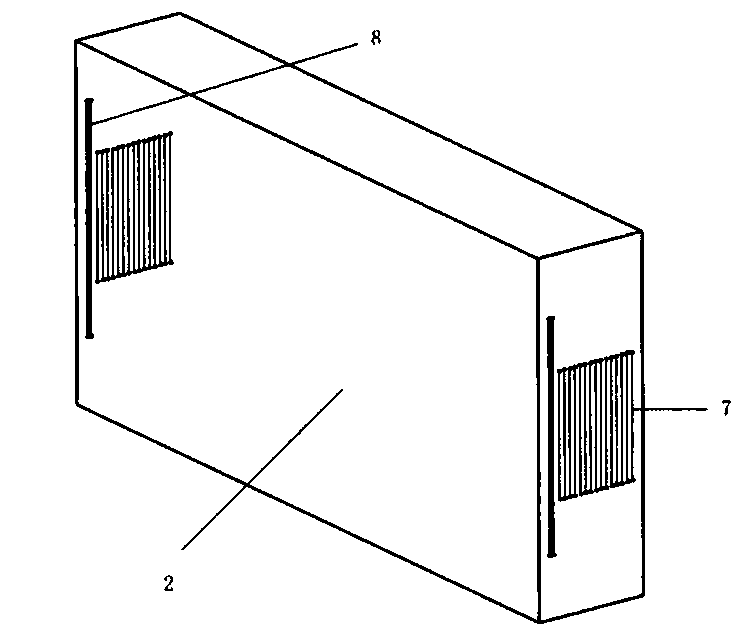

[0028] Such as image 3 As shown, the glass line ruler 2 is a rectangular parallelepiped glass block, and light curtain marking lines 8 and accurate reticle scales 7 are arranged on symmetrical positions on two opposite sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com