Concrete axial tension fixed-section breaking device and method

An axial tensile, concrete technology, applied in measuring devices, using stable tension/pressure testing materials strength, instruments, etc., can solve problems such as increased test errors, difficulties, and difficulty in clamping specimens, reducing The effect of random error, accurate sample data, and accurate positioning section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

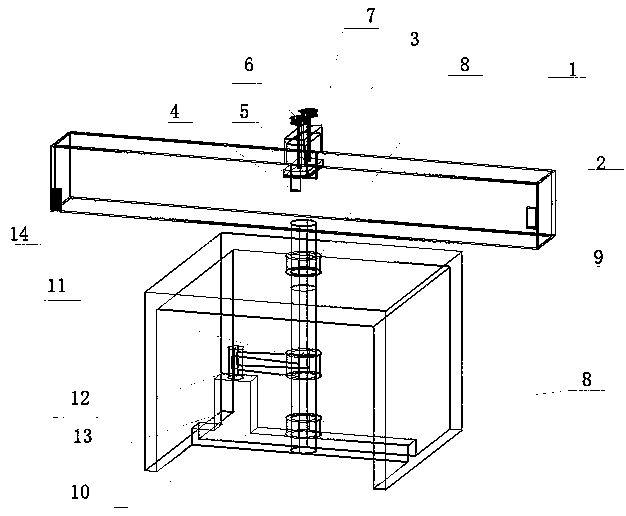

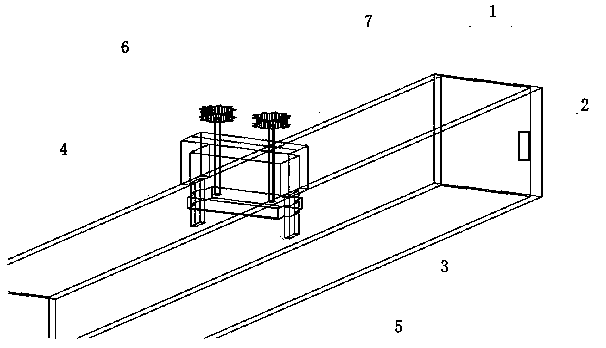

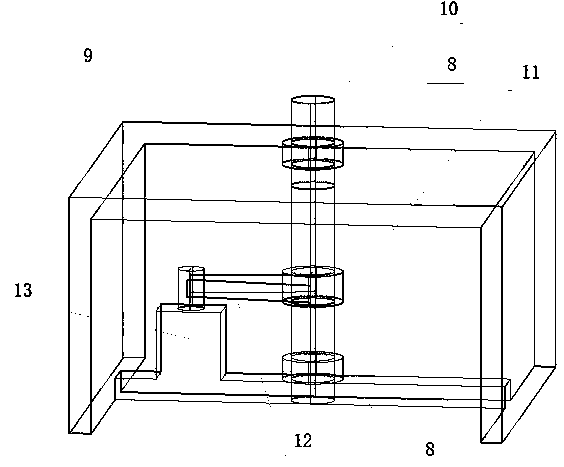

[0030] Such as Figure 1 to Figure 5 Among them, a concrete axial tensile constant section fracture device is characterized in that it includes a base 9, a driving mechanism, a clamping groove 1 and a clamping mechanism; the driving mechanism is connected to the base 9, and the clamping groove 1 is connected to the driving Mechanism connection, the clamping mechanism is connected with the clamping groove 1; the driving mechanism drives the clamping groove 1 to rotate; the clamping groove 1 is a groove-shaped box with an upper opening, and a laser 14 is provided at one end of the closure, and a laser 14 is provided at the other end. There are movable doors 2 that can be opened and closed. The structure is simple, the concrete sample is placed in the clamping groove 1, the driving mechanism and the supporting clamping groove 1 are fixed by the base 9, clamped and fixed by the clamping mechanism, the fracture surface is positioned, and the clamping groove 1 is driven to rotate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com