Mechanical automatic tracking winding displacement device

A technology of automatic tracking and cable arrangement, applied in coil manufacturing, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of complex equipment design, relatively high cost, time-consuming and labor-intensive, etc., and achieve simple structure and low cost , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

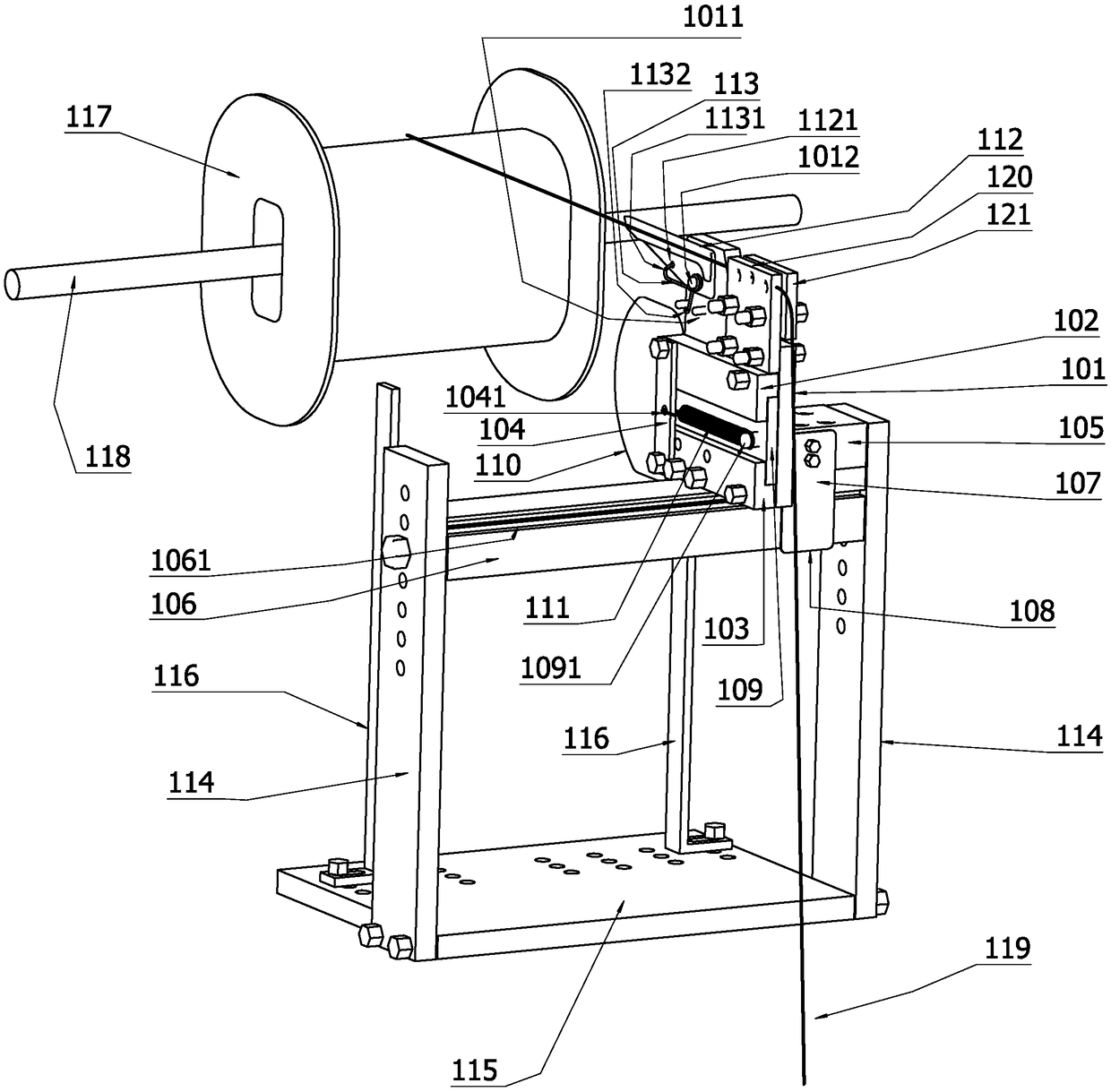

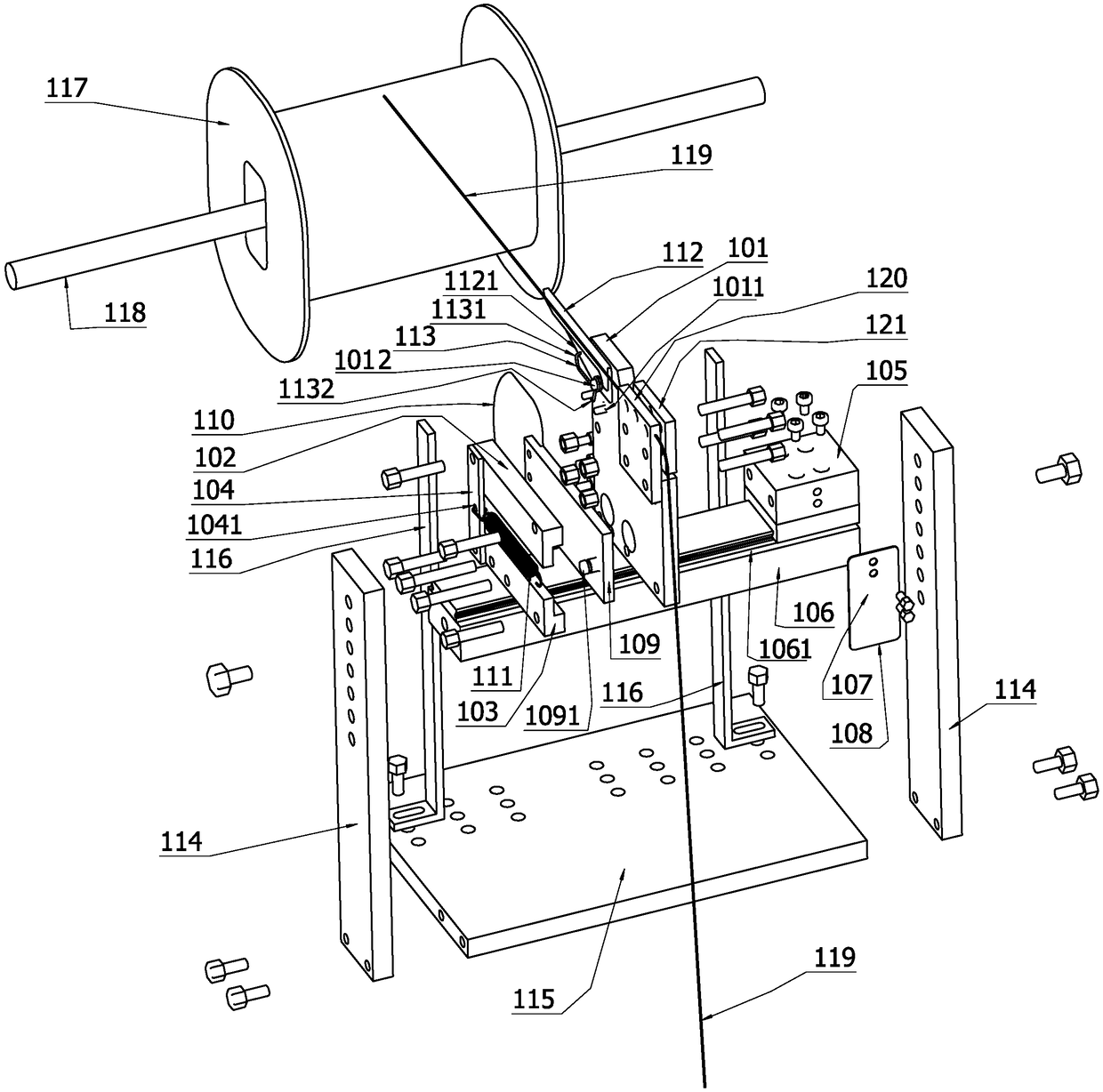

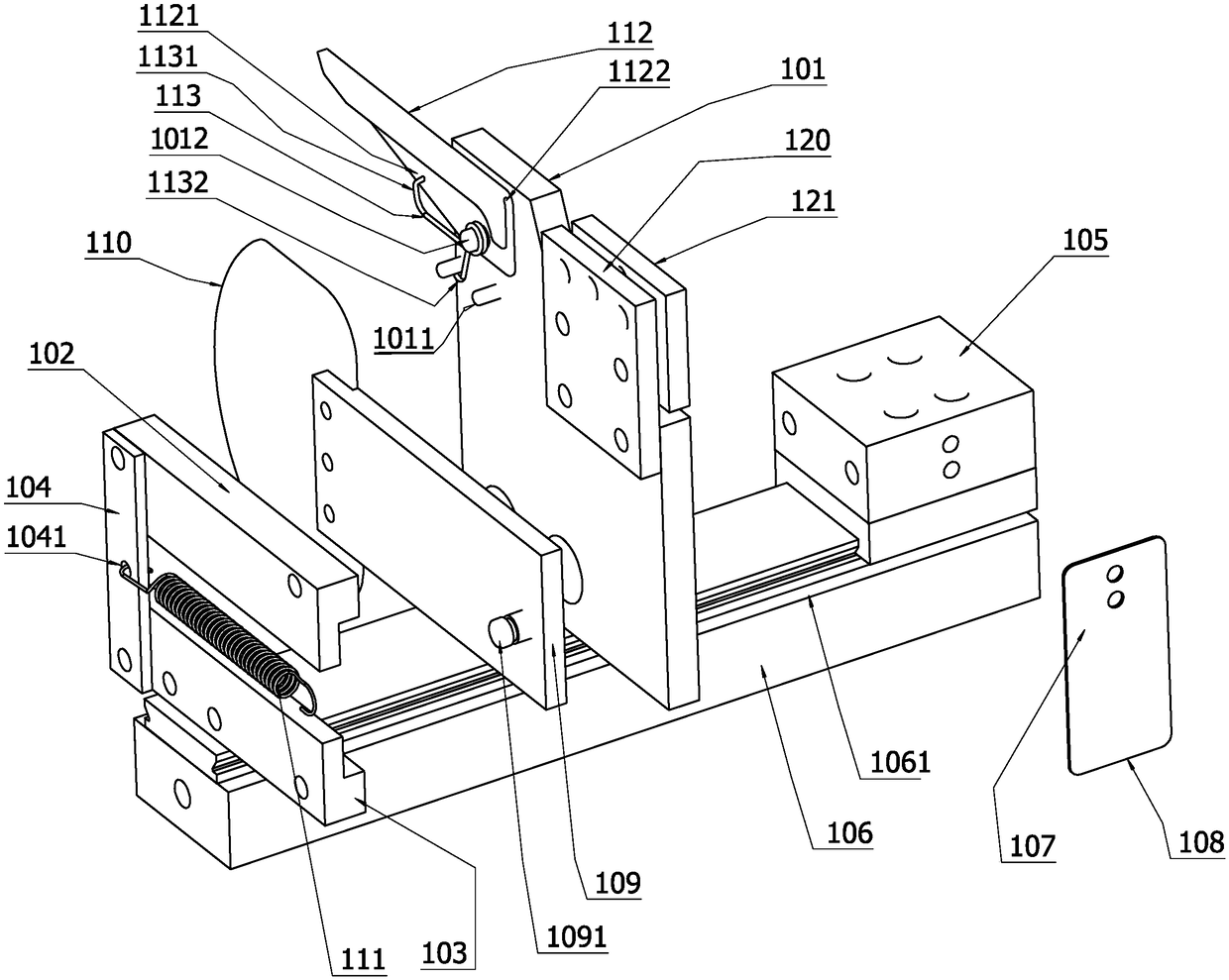

[0012] Example: such as Figure 1-Figure 4 As shown, in this embodiment, the present invention includes a frame, a slide rail, a slider, a base plate, a depressing tongue, a piston, a piston seat, a probing tongue, a torsion spring, a spring, a wire damping device, a limit rod, etc. . The frame consists of the lower base plate (115), the left and right columns (114) and the upper beam (106) fixed into a square frame by screws, the lower base plate (115) can be combined with the fixed winding machine, etc.; The screw is installed and fixed with a slide rail (1061) along the direction of the upper beam, and a slide block (105) is installed on the slide rail (1061), and the slide block (105) can freely move left and right along the slide rail (1061) direction on the slide rail (1061). Sliding; the vertical surface of the slide rail (1061) of the slide block (105) is fixed with a base plate (101) by screws, and the upper and lower piston seats (102, 103), the upper and lower pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com