Motor end cover, and motor

A motor end cover and cover body technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of hidden quality problems, easy water ingress at the junction of the bottom of the outlet structure and the end cover, complicated operation procedures, etc., and achieve the processing cost. Low, improve the sealing effect of the wire, the effect of simple installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

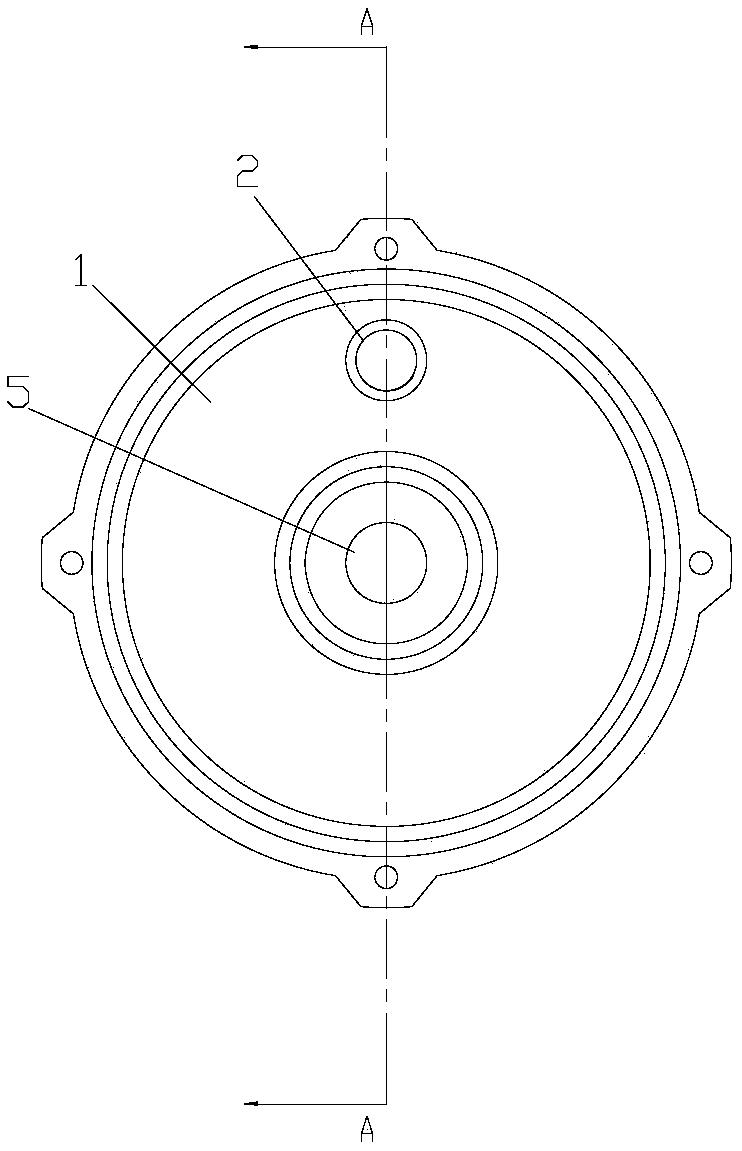

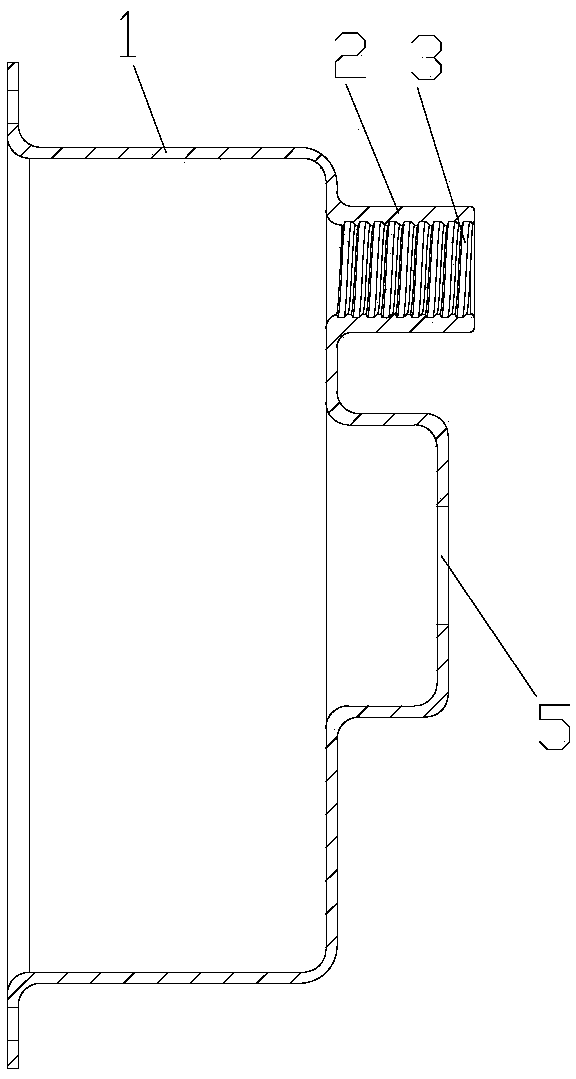

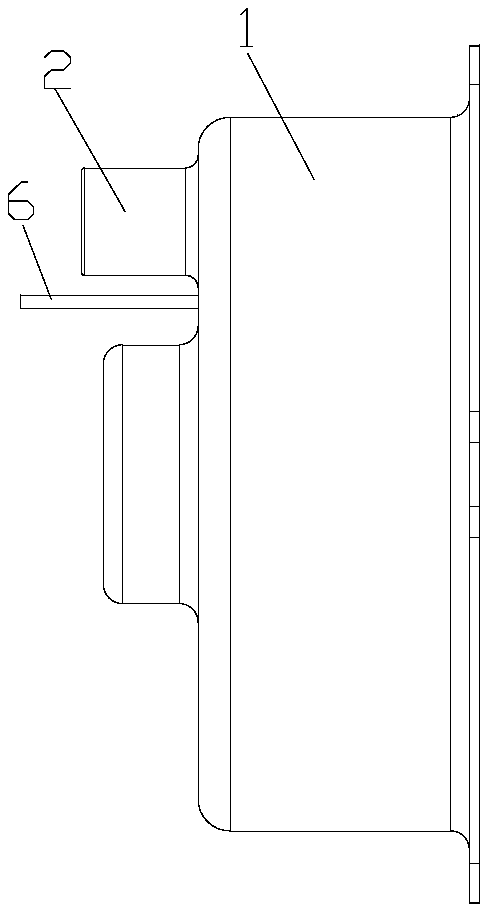

[0022] see in conjunction Figure 1 to Figure 5 As shown, according to the embodiment of the present invention, the motor end cover includes a cover body 1 and a wire outlet structure arranged on the cover body 1 , and the wire outlet structure is integrally formed with the cover body 1 .

[0023] Since the outlet structure of the motor end cover is integrally formed with the cover body 1, there is no need to specially set outlet connectors, and no need to manually thread outlet nozzles, which can effectively reduce procedures, simplify the installation process, lower processing costs, and improve production efficiency. Since the outlet structure and the cover body 1 are integrally formed, the seamless connection between the outlet structure and the cover body 1 can be realized, the sealing effect of the wire passing is improved, and the hidden danger of rainwater entering the motor cavity from the bottom of the outlet structure is solved, which improves the motor performance. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com