Remaining oil amount monitoring system, method and device for oiling pump of mechanical equipment, and server

A technology of mechanical equipment and oil injection pump, which is applied in the field of Internet of Things, can solve the problems of inspection action dependence, low efficiency, and poor reliability, and achieve the effect of improving monitoring efficiency and reliability, and solving low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments of the present invention will be further described in detail below in conjunction with the drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the embodiments of the present invention, rather than to limit the embodiments of the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all structures related to the embodiments of the present invention.

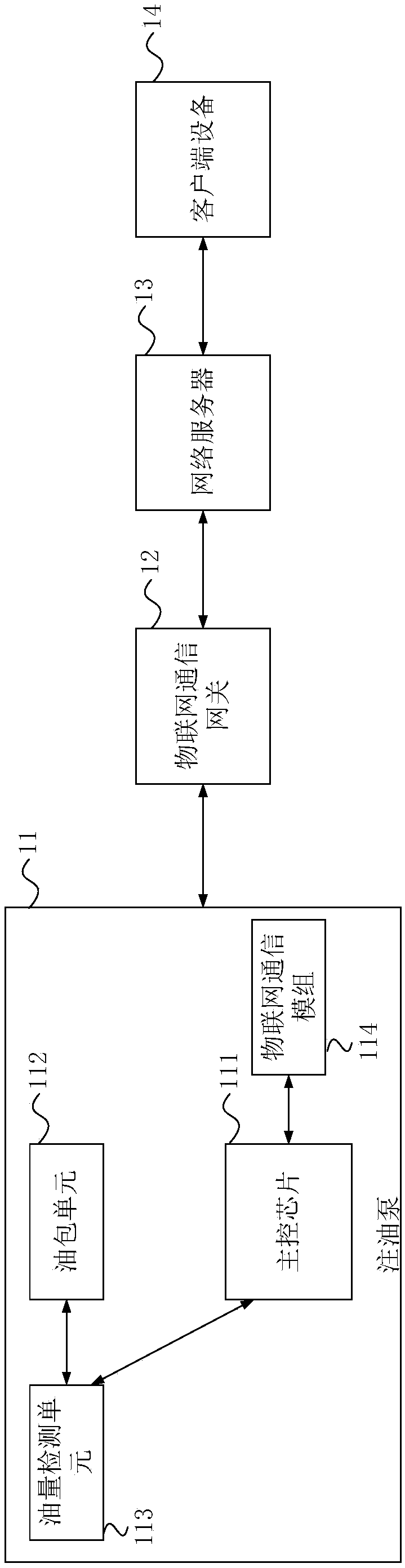

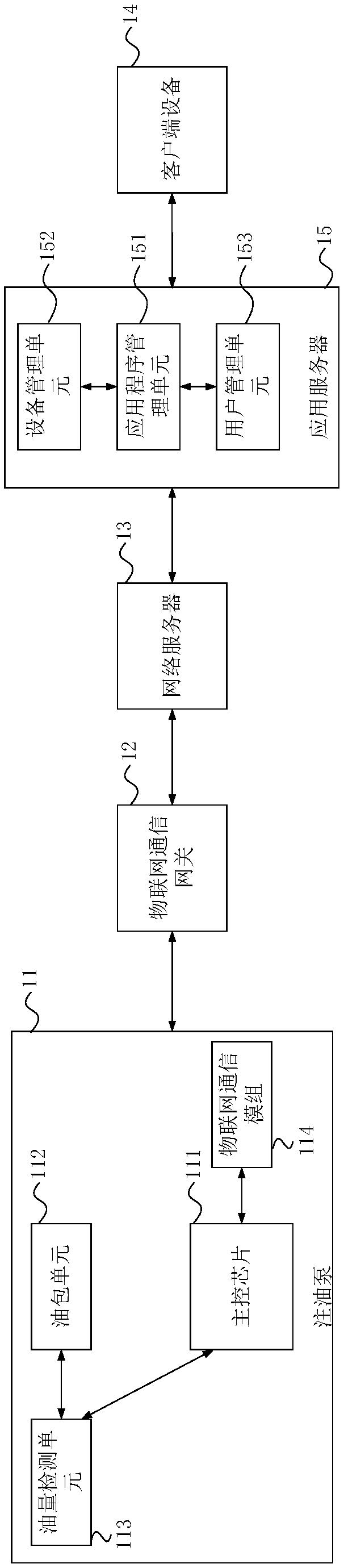

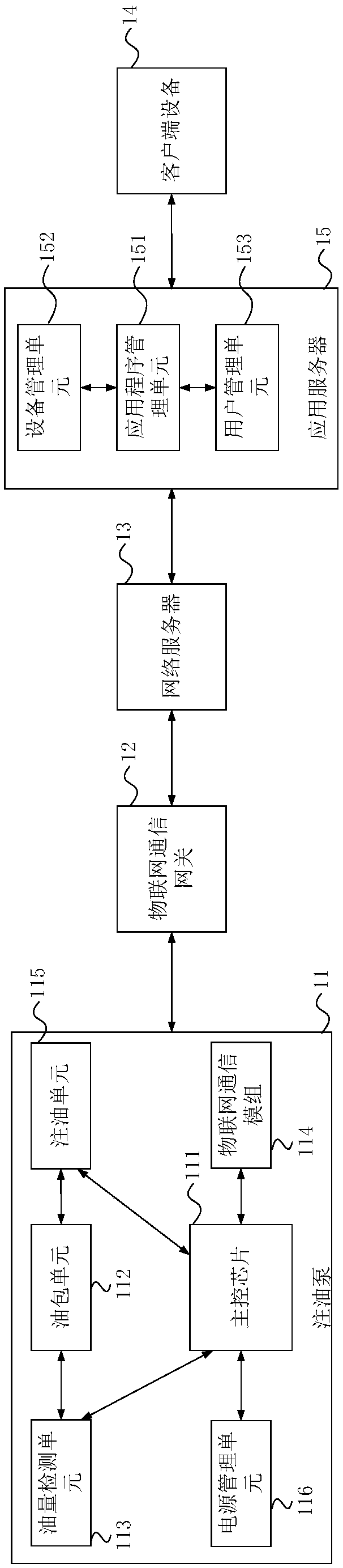

[0043] figure 1 It is a structural schematic diagram of an oil injection pump residual oil monitoring system for mechanical equipment provided in an embodiment of the present invention. The system includes: an oil injection pump 11 set on the mechanical equipment, an Internet of Things communication gateway 12, a network server 13, and a client device 14; Wherein, the oil injection pump 11 includes a main control chip 111, an oil bag unit 112, an oil quantity detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com