High-strength steel plate and method for manufacturing same

A high-strength steel sheet, a technology for manufacturing methods, applied in manufacturing tools, furnace types, hot-dip plating processes, etc., can solve the problems of reduced ductility and stretch flangeability, and achieve excellent ductility and stretch flangeability, and fuel consumption. The effect of improving and improving collision safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

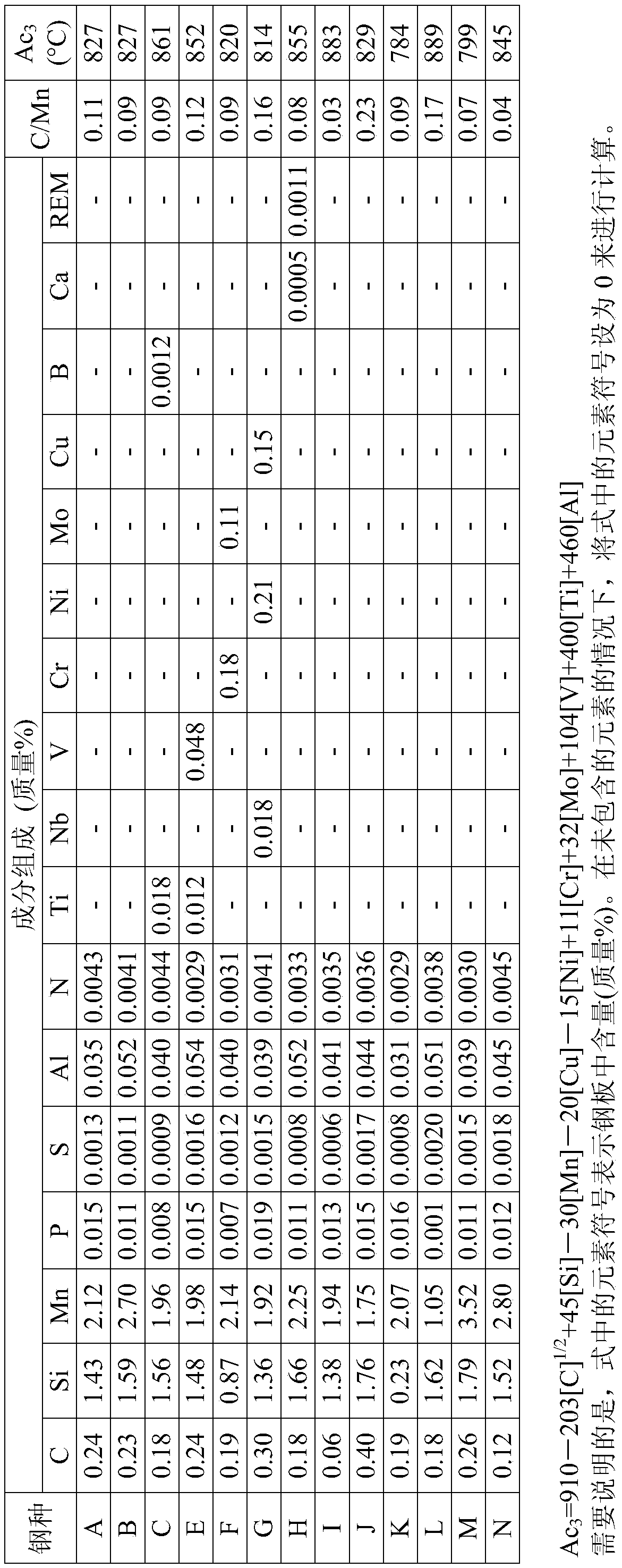

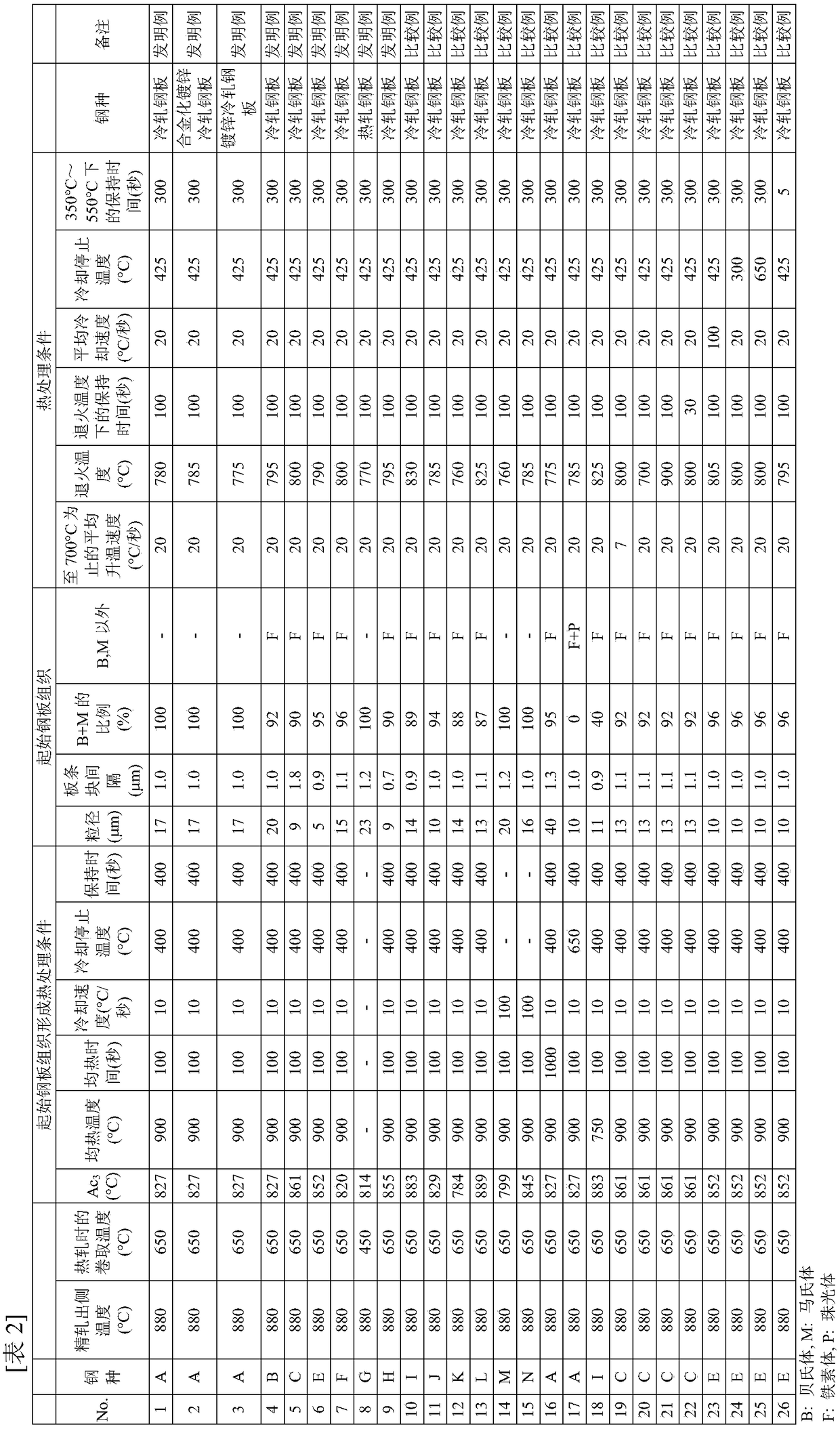

[0106] Next, the action and effect of the high-strength steel sheet and its manufacturing method of the present invention will be described using examples.

[0107] Vacuum-melted steel having the composition shown in Table 1 was smelted in a laboratory to produce a thin slab with a thickness of 20 mm. These thin plate slabs were rolled at a heating temperature of 1250°C and a finishing exit temperature of 880°C, cooled to 650°C at a rate of 40°C / sec after rolling, and coiled at 650°C for heat treatment. The hot-rolled sheet thus obtained was pickled with hydrochloric acid and cold-rolled at a reduction ratio of 50% to produce a cold-rolled steel sheet with a thickness of 1.2 mm. Next, it was heat-treated under the heat treatment conditions shown in Table 2 to manufacture out of cold-rolled steel. In addition, this cold-rolled steel plate was used as a starting steel plate.

[0108] In addition, vacuum-melted steel having the composition shown in Table 1 was smelted in a labo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap