Automatic mold separating device with double-cooling function

A double cooling and mold technology, applied in the field of machinery, can solve the problems of inability to cool the product, inconvenient disassembly and assembly of the device, complex structure, etc., and achieve the effects of prolonging the service life, facilitating the placement of tools, and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

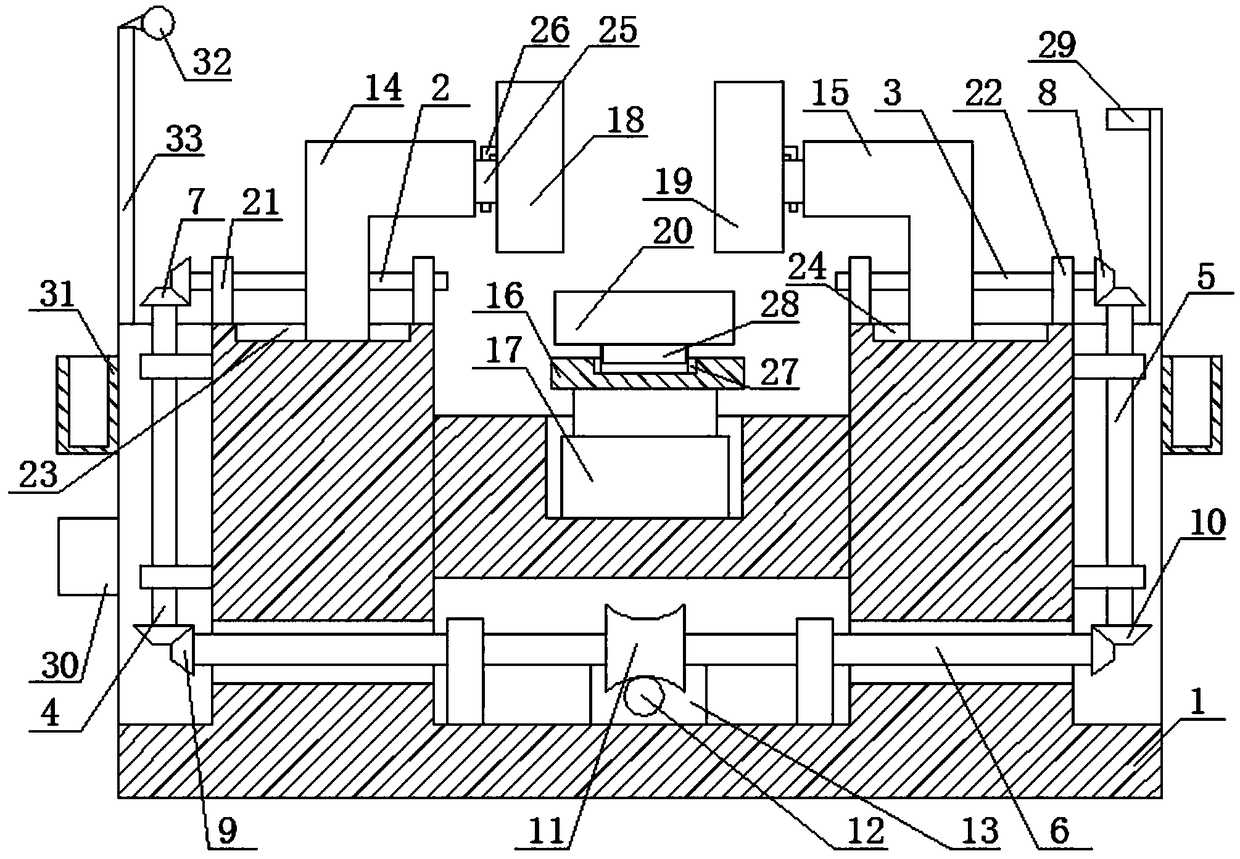

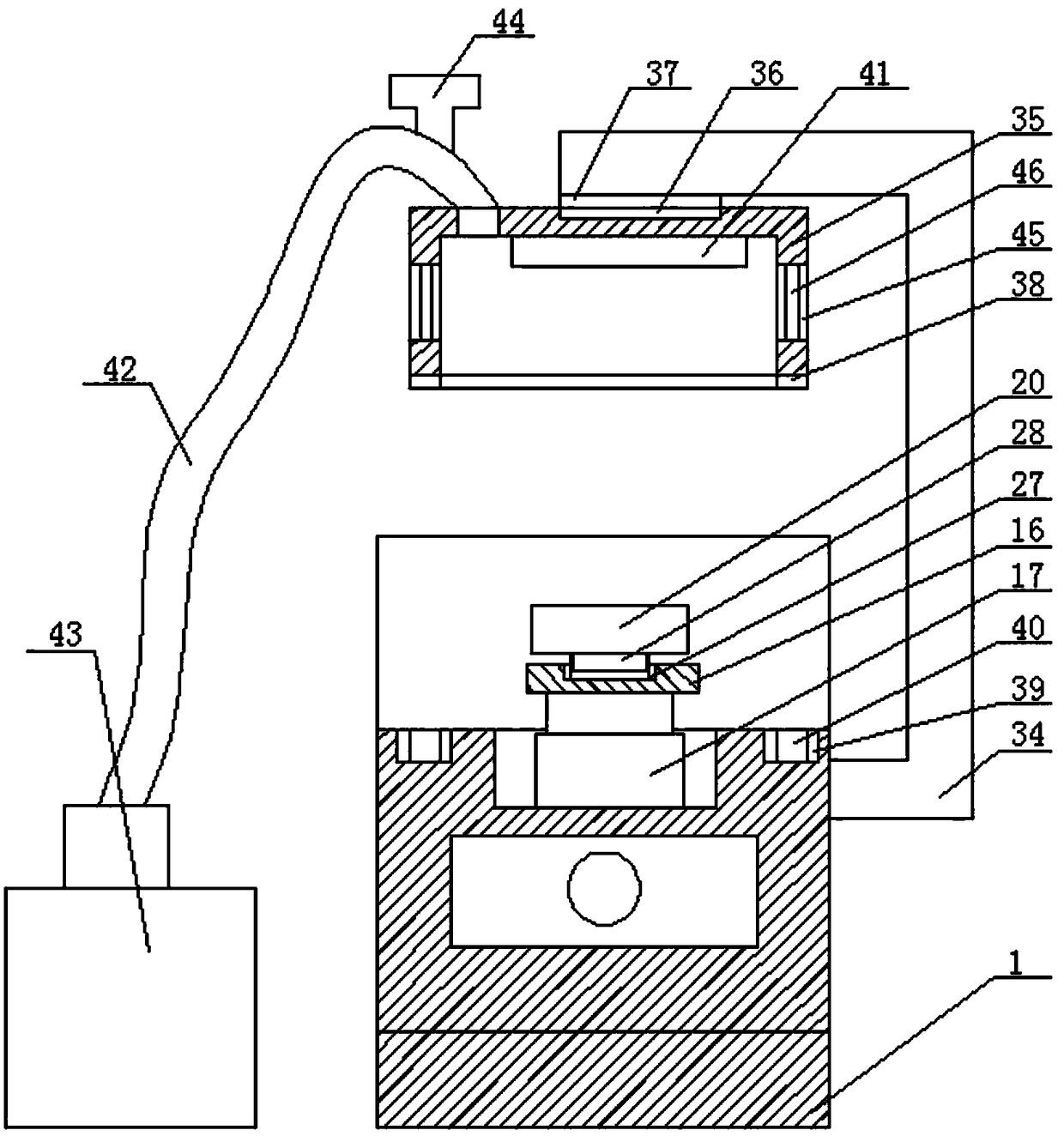

[0038] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

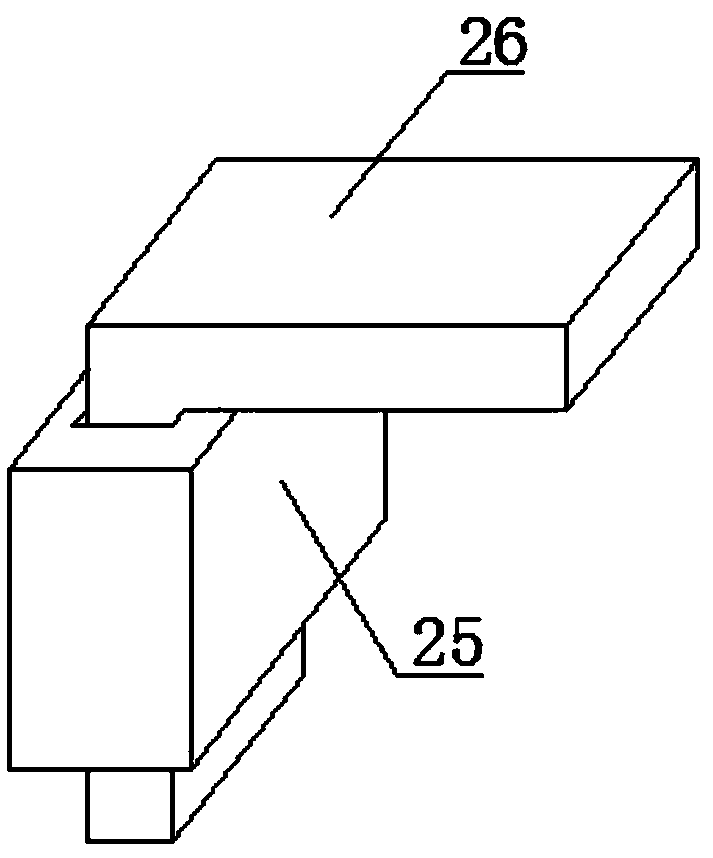

[0039] Such as Figure 1 to Figure 3As shown, an automatic mold separation device with double cooling function, including support frame 1, ball screw I2, ball screw II3, shaft I4, shaft II5, shaft III6, bevel gear set I7, bevel gear set II8, bevel Gear set III9, bevel gear set IV10, turbine 11, worm 12, servo motor 13, flange I14, flange II15, fixed plate 16, hydraulic cylinder 17, left mold 18, right mold 19 and bottom mold 20; the ball The screw I2 and the ball screw II3 are rotatably connected to both sides of the top of the support frame 1 through the screw support I21 and the screw support II22 respectively, and the ball screw I2 and the ball screw II3 are collinear and arranged horizontally The shaft I4 and the shaft II5 are respectively connected to both sides of the support frame 1 through bearings, and the shaft I4 and the shaft II5 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com