Weather-resistant multi-layer bathroom cabinet board and preparation method thereof

A bathroom cabinet, weather resistance technology, applied to other rubber adhesives, adhesive types, adhesives, etc., can solve the problems of poor process stability, humidity, water absorption and mildew of wooden cabinet boards, and achieve excellent waterproof performance and ensure The effect of life and avoiding warping and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

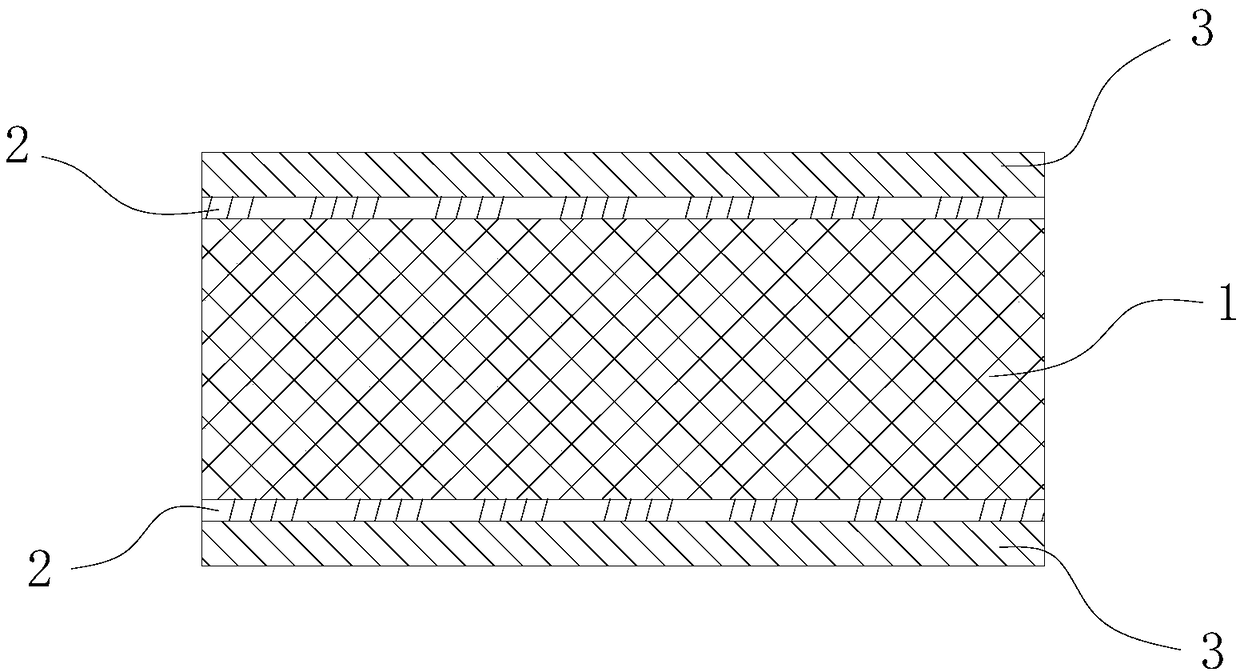

[0032] The present invention also provides a method for preparing a weather-resistant multilayer bathroom cabinet, comprising the following steps:

[0033] (1) Stir the wood chips and the first adhesive evenly, and set aside;

[0034] (2) Weigh the raw material of the waterproof adhesive layer according to the formula, mix and prepare it, pour the waterproof adhesive layer into the mold to form a waterproof adhesive layer on one side, then cover the fiber cloth to form a fiber cloth layer, and then put the The mixture of wood chips and the first adhesive is added, and then the first pressing is carried out; then the fiber cloth is laid to form a fiber cloth layer, and then the waterproof adhesive layer raw material is poured in again, and the pressing is carried out again to obtain the semi-finished cabinet board;

[0035] (3) Put the semi-finished cabinet board in step (2) into the drying tunnel, bake at a temperature of 40-60° C. for 1-3 minutes, then demould, and obtain the...

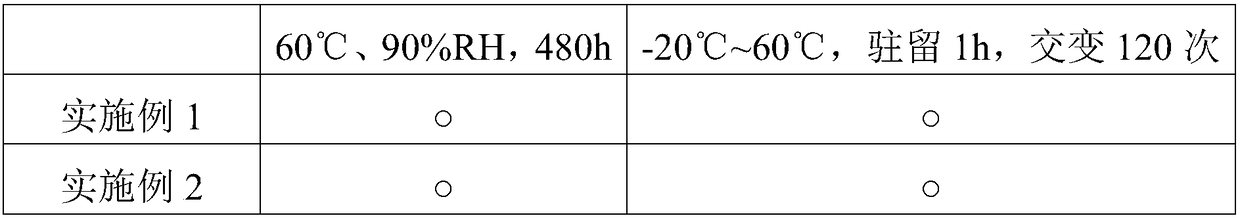

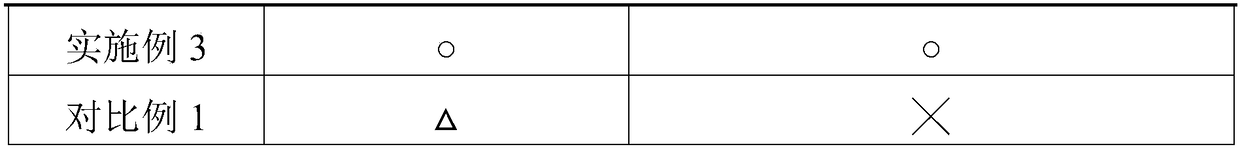

Embodiment 1

[0040] A preparation method of weather-resistant multi-layer bathroom cabinet board:

[0041] (1) Stir the wood chips and toluene diisocyanate evenly, and set aside;

[0042] (2) Weigh the raw material of the waterproof adhesive layer according to the formula, mix and prepare it, pour the waterproof adhesive layer into the mold to form a waterproof adhesive layer on one side, and then cover two layers of 3K carbon fiber cloth to form a fiber cloth layer, then step (1) ) in the mixture of wood chips and toluene diisocyanate is added, followed by the first pressing, the pressing pressure is 8Mpa, and the pressing time is 5min;

[0043] Then spread two layers of 3K carbon fiber cloth to form a fiber cloth layer, then pour in the waterproof adhesive layer raw material again, and press again, the pressing pressure is 8Mpa, the pressing time is 8min, and the semi-finished cabinet board is obtained;

[0044] The above-mentioned waterproof adhesive layer includes: 42 parts by weight ...

Embodiment 2

[0047] A preparation method of weather-resistant multi-layer bathroom cabinet board:

[0048] (1) Stir the wood chips and toluene diisocyanate evenly, and set aside;

[0049] (2) Weigh the raw material of the waterproof adhesive layer according to the formula, mix and prepare it, pour the waterproof adhesive layer into the mold to form a waterproof adhesive layer on one side, and then cover two layers of 3K carbon fiber cloth to form a fiber cloth layer, then step (1) ) in the mixture of wood chips and toluene diisocyanate is added, followed by the first pressing, the pressing pressure is 3Mpa, and the pressing time is 5min;

[0050] Then spread two layers of 3K carbon fiber cloth to form a fiber cloth layer, then pour in the waterproof adhesive layer raw material again, and press again, the pressing pressure is 10Mpa, and the pressing time is 8min to obtain the semi-finished cabinet board;

[0051] The above-mentioned waterproof adhesive layer includes: 30 parts by weight of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap