A kind of high temperature resistant conveyor belt and its manufacturing process

A conveyor belt and high temperature resistant technology, applied in the field of conveyor belts, can solve the problems of food separation, inconvenient use of conveyor belts, and easy aging, etc., and achieve the effect of not easy to stick, excellent overall performance, and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

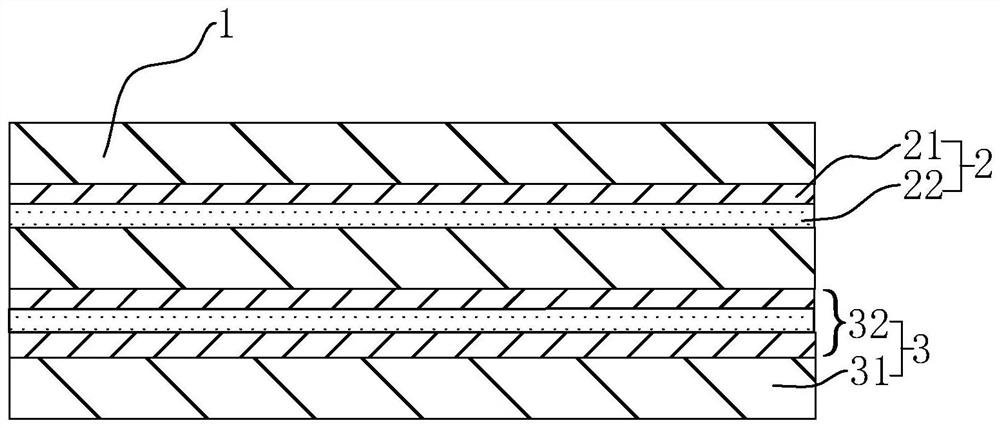

[0047] Embodiment 1: a kind of high temperature resistant conveyer belt, comprises the following steps to produce and obtain:

[0048] Step 1, fabric setting: carry out setting treatment on the high temperature resistant fabric layer 31, the temperature of setting treatment is 180°C, the vehicle speed is 18m / min, the tension is 300kg, and the high temperature resistant fabric layer 31 after setting is obtained;

[0049] Step 2, viscose glue: evenly apply PU glue to one surface of the shaped high-temperature-resistant fabric layer 31 obtained in step 1, and form the first adhesive layer 21 on the high-temperature-resistant fabric layer 31;

[0050] Step 3, drying material: heat the granular TPU-90A at a temperature of 100-105°C for 2.5 hours to remove moisture, and then melt the dried TPU-90A;

[0051] Step 4, bonding: one surface of the shaped high temperature resistant fabric layer 31 with the first adhesive layer 21 obtained in step 2 is coated with TPU-90A to form a second ...

Embodiment 2

[0056] Embodiment 2: a kind of high temperature-resistant conveyor belt, the difference with embodiment 1 is that the weight used per square meter of the first adhesive layer 21 is 8g, and the weight used per square meter of the second adhesive layer 22 is 30g.

Embodiment 3

[0057] Embodiment 3: a kind of high temperature-resistant conveyor belt, the difference with embodiment 1 is that the weight used per square meter of the first adhesive layer 21 is 12g, and the weight used per square meter of the second adhesive layer 22 is 25g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com