Full-automatic IC programmer

A burning machine, fully automatic technology, applied in the direction of conveyor objects, transportation and packaging, can solve problems such as affecting efficiency, affecting burning efficiency, low efficiency, etc., to improve burning efficiency, simple control procedures, and improve the overall The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

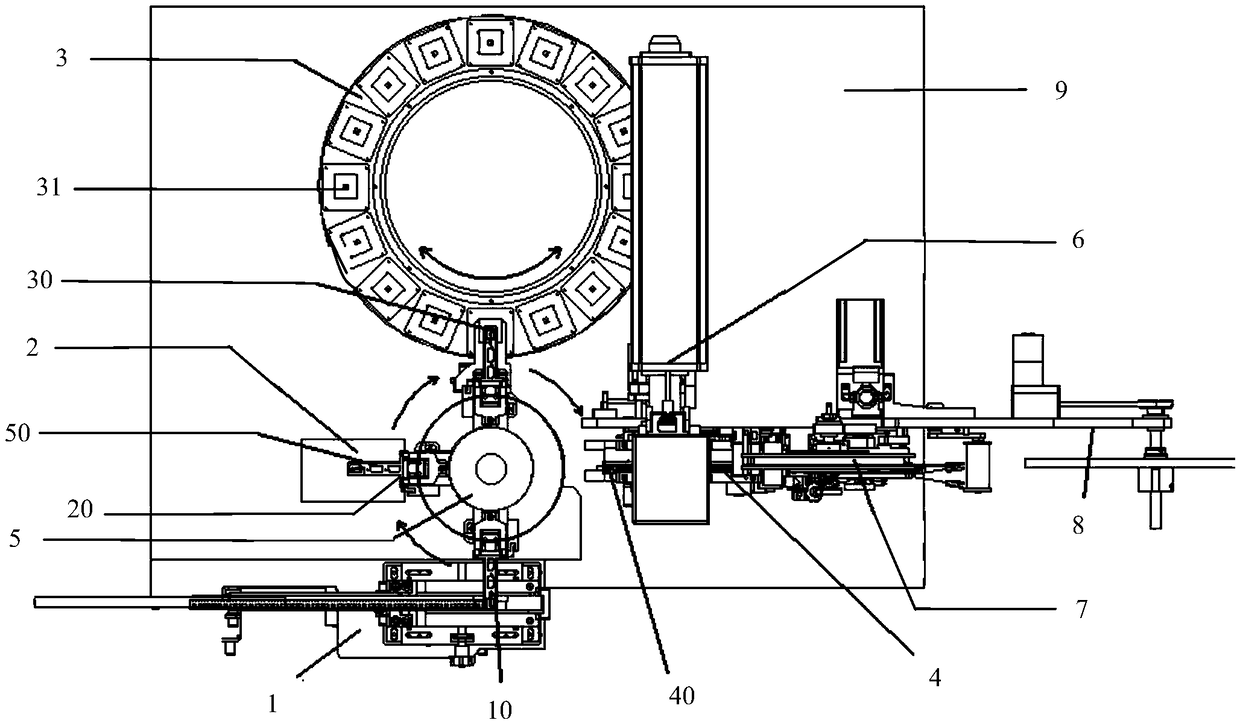

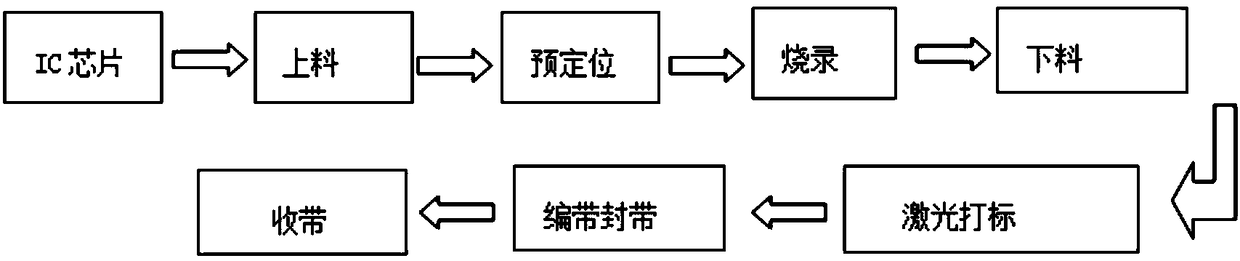

[0033] Such as figure 1 A fully automatic IC programming machine shown includes a loading component 1, a positioning component 2, a programming component 3, a blanking component 4, and a turntable reciprocating manipulator component 5. IC chips are loaded from the loading component 1, After being pre-positioned by the positioning component 2, enter the burning component 3 to complete the burning program, and finally unload through the unloading component 4.

[0034] Wherein, the turntable reciprocating manipulator assembly 5 includes a turntable and three manipulators 50 rotating around the center of the turntable, and each manipulator 50 performs pick-and-place operations for IC chips.

[0035] The material outlet 10 of the loading component, the material inlet and outlet 20 of the positioning component, the material inlet and outlet 30 of the programming component, and the material inlet 40 of the unloading component are evenly arranged along the center of the turntable in s...

Embodiment 2

[0053] On the basis of Embodiment 1, the programming component 3 can also be improved.

[0054] The burning assembly 3 includes a center of rotation, and a plurality of burning stations evenly arranged along the center of rotation, an IC chip carrier 31 is arranged above the burning station, and each IC chip carrier 31 rotates along the The center rotates, and the IC chip falls into the IC chip carrier 31 through the inlet and outlet 30 of the programming assembly, rotates clockwise or counterclockwise along the center of rotation for programming, and finally returns to the inlet and outlet 30 of the programming assembly , to complete the burning program.

[0055] The action process of this technical solution is: after the manipulator 50 puts the IC chip to be burned into the material inlet and outlet 30 of the burning assembly, the IC chip carrier 31 rotates an angle, and the IC chip to be burned is placed on the IC chip carrier 31 Continue the burning program, another blank...

Embodiment 3

[0059] On the basis of Embodiment 1 or 2, the unloading component 4 is preferably equipped with a laser marking function module 6 , a tape sealing module 7 and a tape take-up module 8 .

[0060] Further, the blanking assembly 4 also includes a laser marking functional module 6, and after the IC chip completes the burning program, it enters the laser marking functional module 6 through the material inlet 40 of the blanking assembly to complete laser marking. Such as figure 1 As shown, the laser marking functional module 6 is preferably arranged above the IC chip.

[0061] Further, the blanking assembly 4 also includes a tape sealing module 7. After the IC chip completes the burning program, it enters the tape sealing module 7 through the material inlet 40 of the blanking assembly for braiding and tape sealing, specifically including The carrier tape with the IC chip and the cover tape are pasted and sealed. Such as figure 1 As shown, the tape sealing module 7 is preferably a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com