Well-drilling acceleration tool

A tool and drilling technology, applied in the field of drill bit supporting equipment, can solve the problem of high drill bit failure rate, achieve the effects of drilling stability, reducing irregular vibration, and protecting the drill string

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

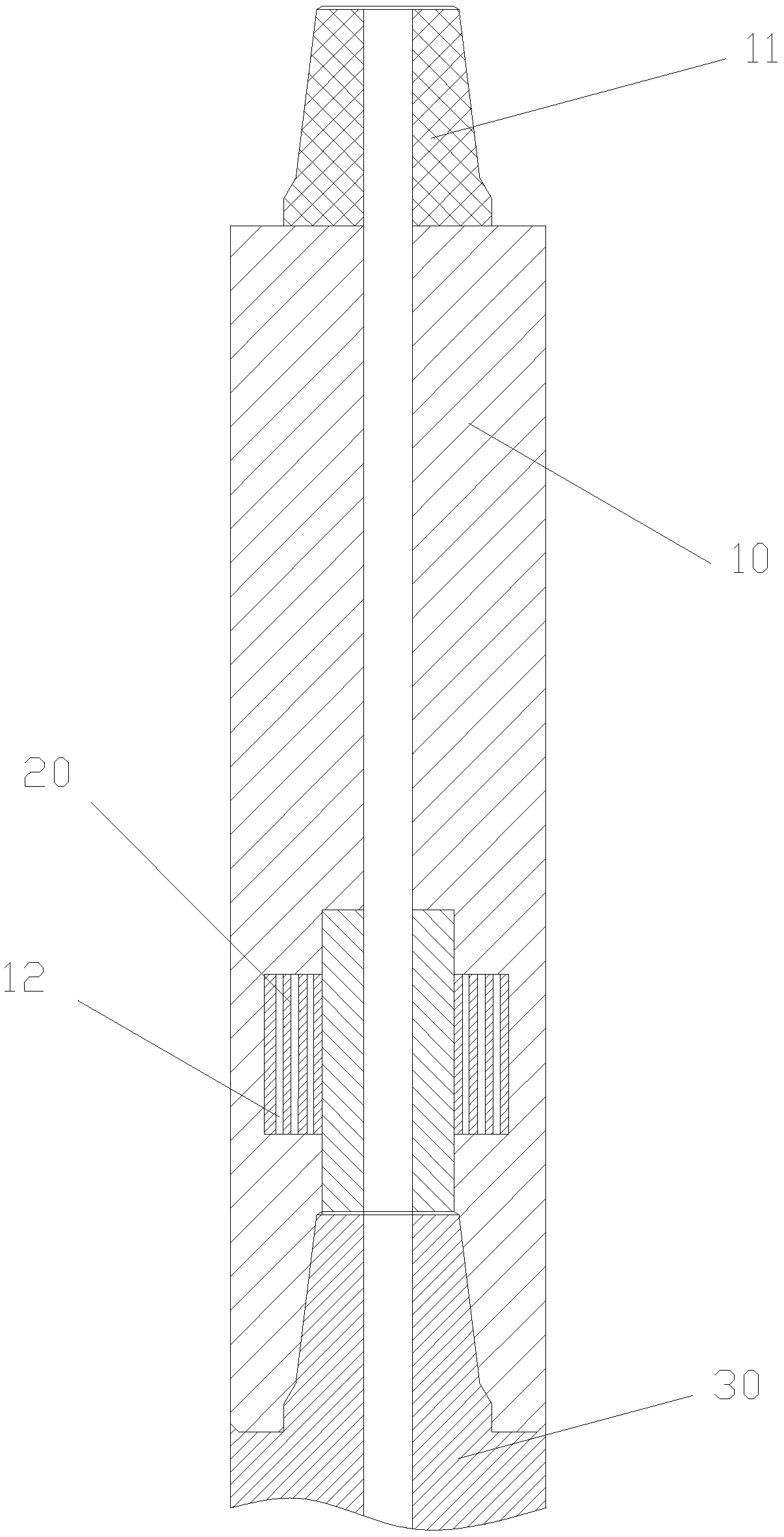

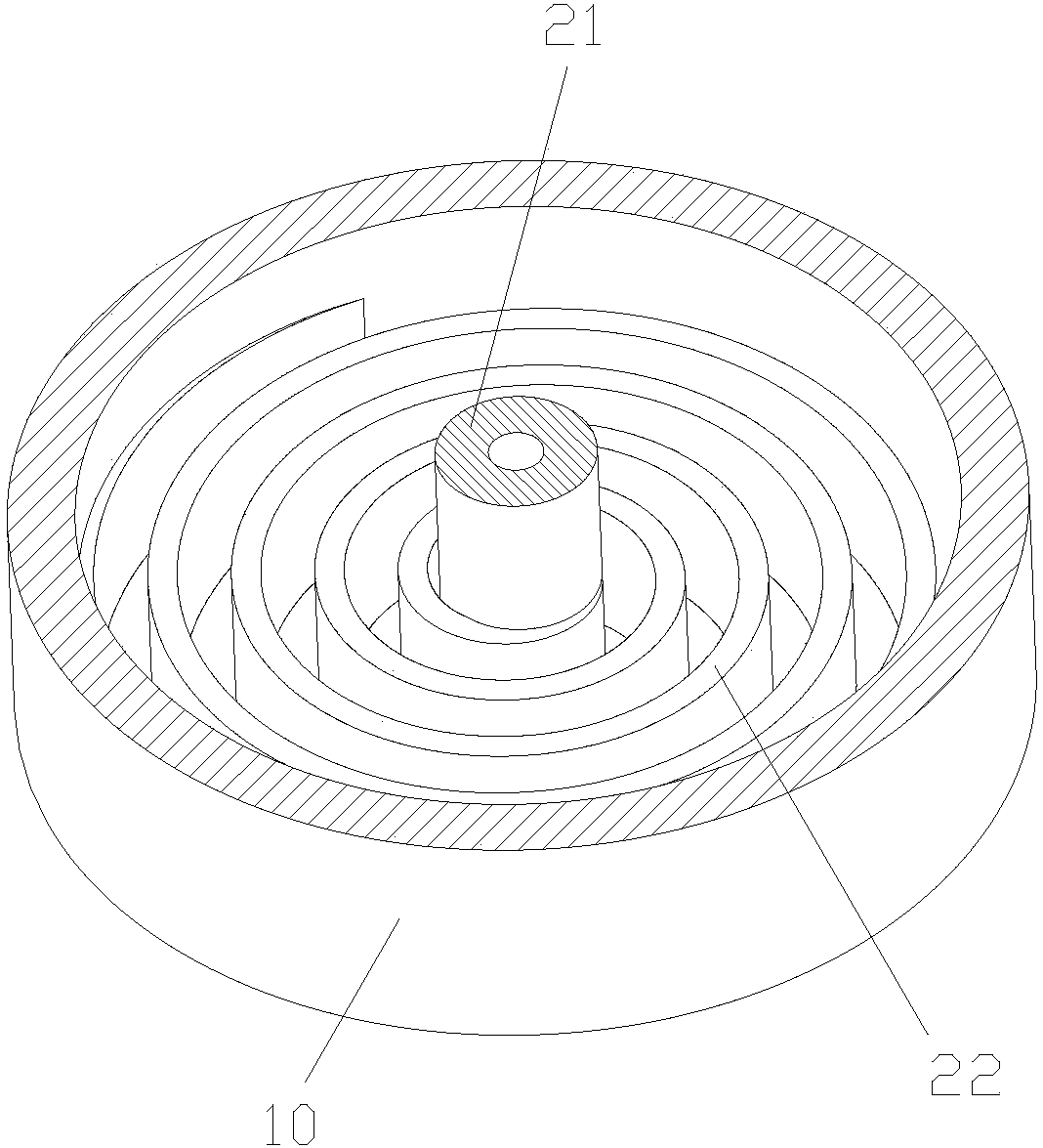

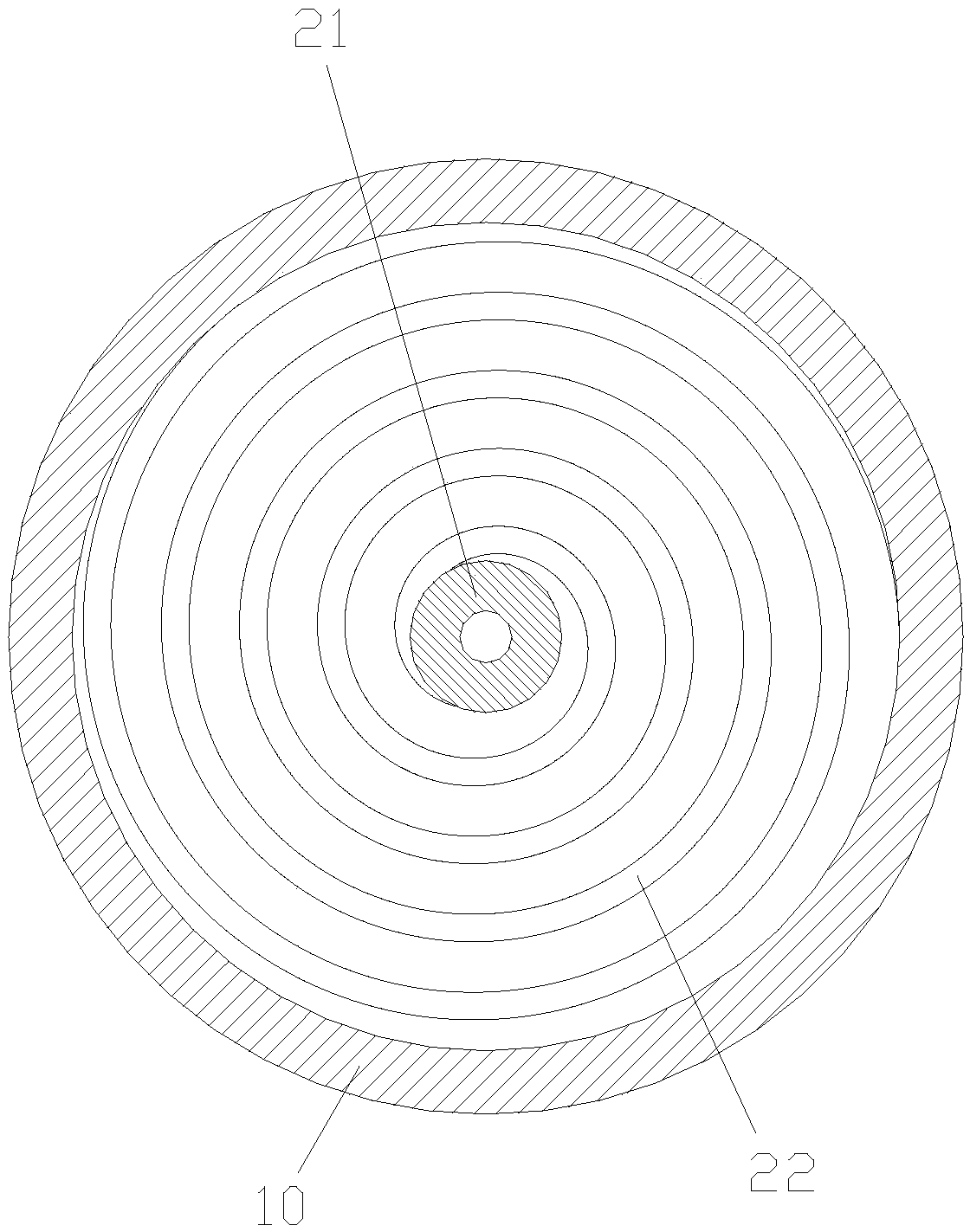

[0018] Such as Figure 1-Figure 3 As shown, as a preferred embodiment, the present invention proposes a drilling speed-increasing tool, including a hollow housing 10, the top of the housing 10 is fixedly provided with a connector 11, and the connector 11 is preferably welded to the housing 10. The connecting head 11 is used to connect with the drill string, the shell 10 is provided with an annular recess 12, and the annular recess 12 is provided with a torque transmission assembly 20, and the torque transmission assembly 20 includes a hollow torsion The shaft 21 and the helical torsion spring piece 22 arranged circumferentially along the torsion shaft 21, one end of the helical torsion spring piece 22 is fixedly connected to the torsion shaft 21, and the other end is fixedly connected to the housing 10, the lower end of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com