Transparent crystal shell and manufacturing process thereof

A manufacturing process and transparent technology, applied in other home appliances, telephone structure, telephone communication and other directions, can solve problems such as poor use of transparent casings, unsatisfactory light transmittance of transparent casings, poor durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

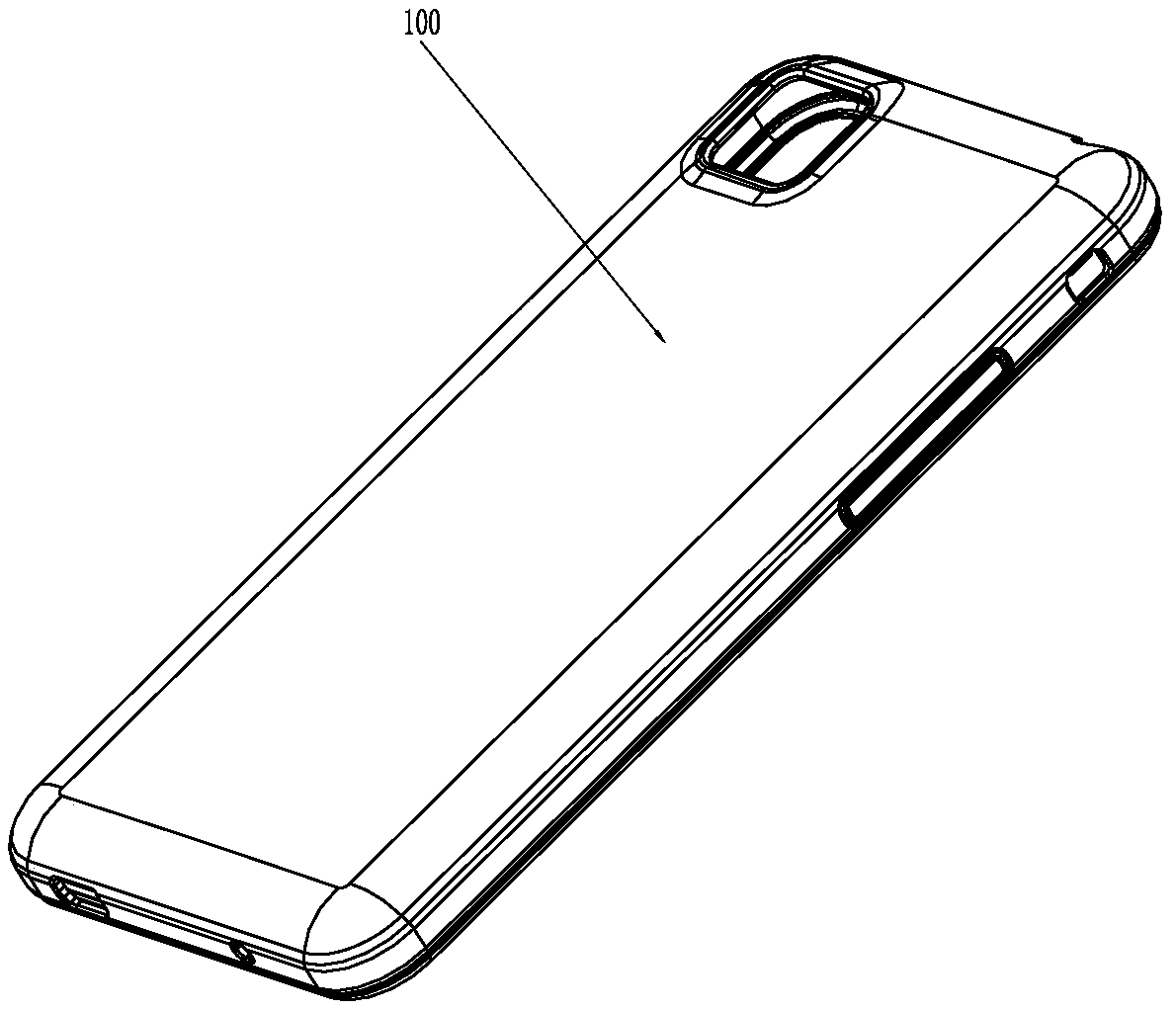

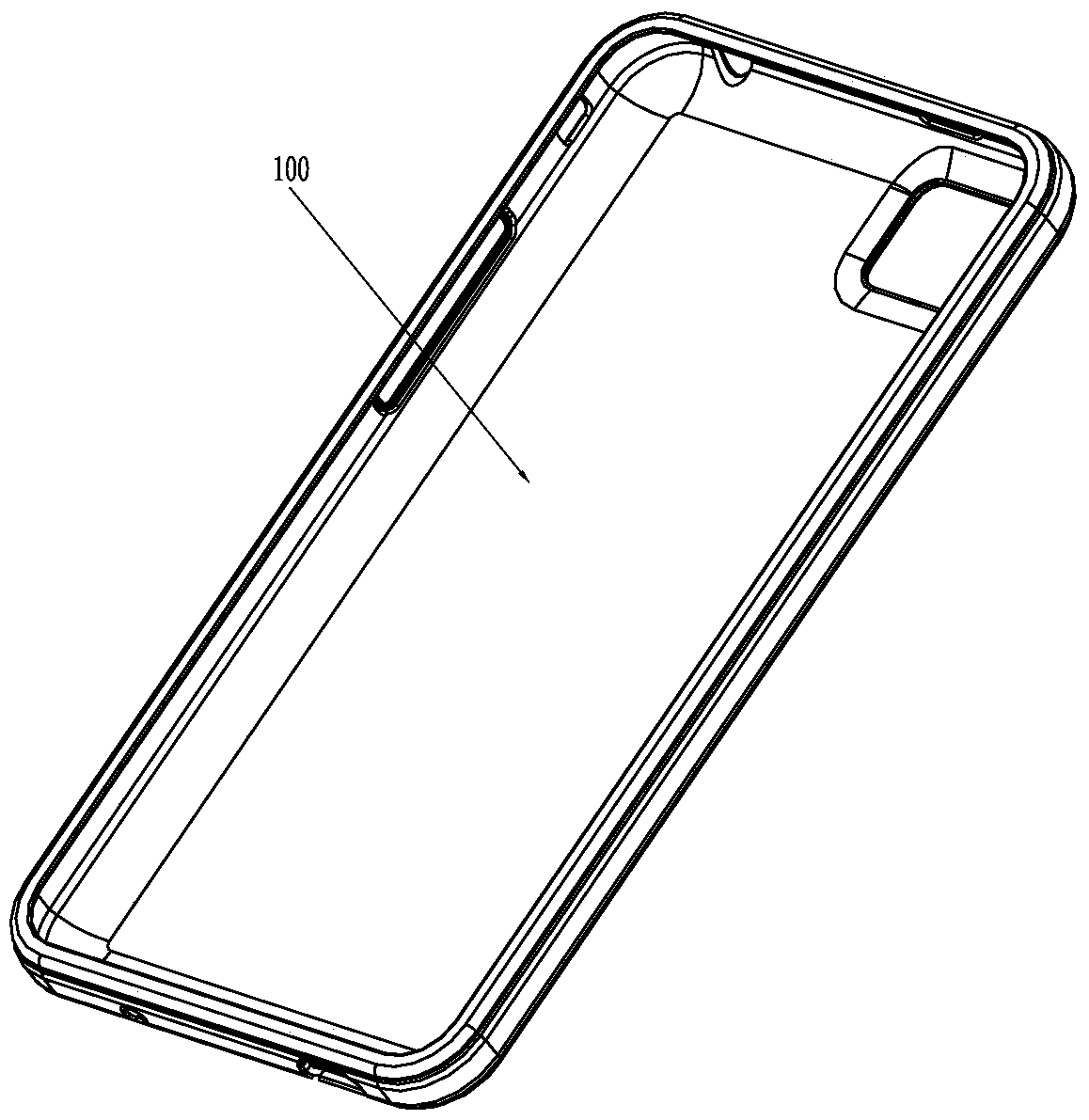

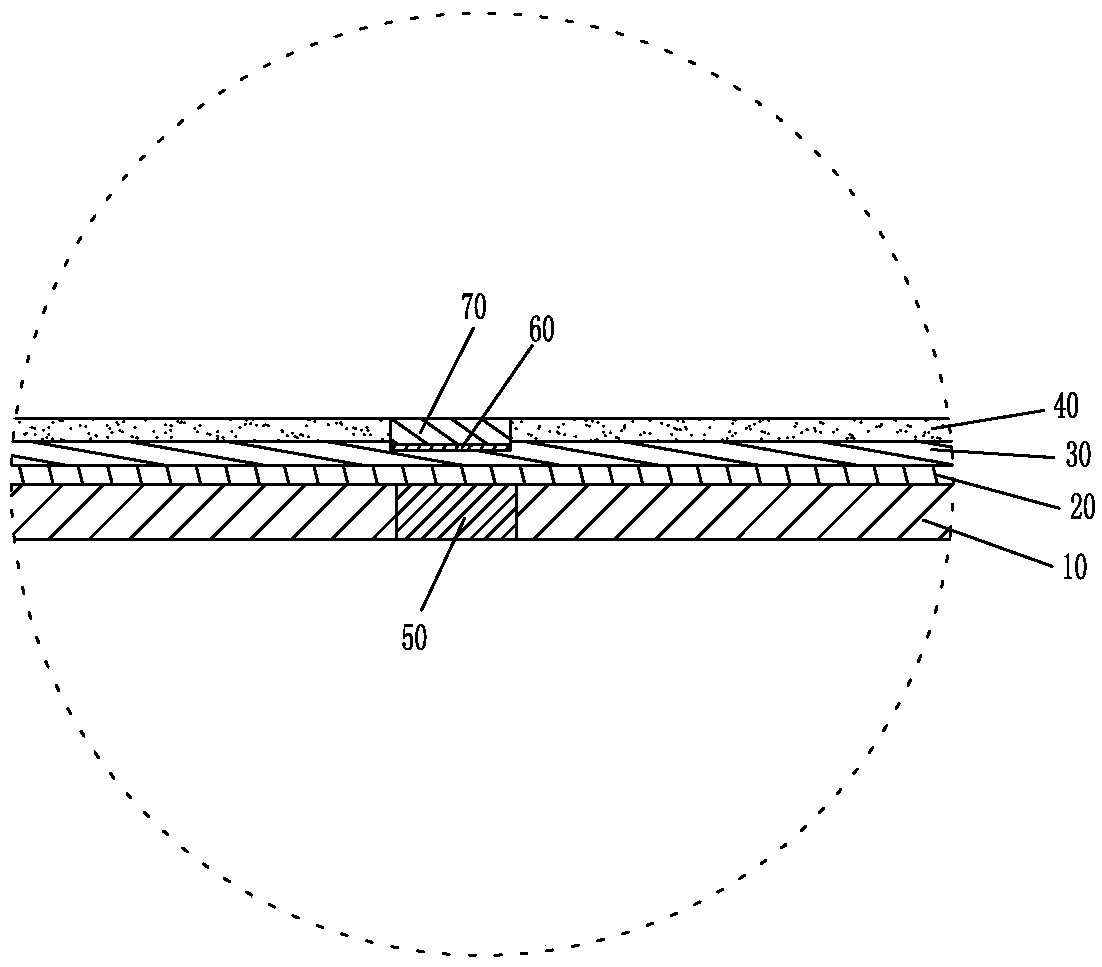

[0032] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the embodiment of the present invention.

[0033] A transparent crystal case, comprising a PC case base 10, the outer surface of the PC case base 10 is sequentially provided with a binder coating 20, a highly transparent silica gel layer 30, and a highly transparent hand feeling ink layer 40 from the inside to the outside, wherein , the high-permeable silicone layer 30 is molded and fixed on the outside of the PC shell base 10, and the high-permeable silicone layer 30 and the PC shell base 10 are combined and fixed through the adhesive coating 20; the high-permeable hand-feeling ink layer 40 is Spray on the outer surface of the high permeability silicone layer 30.

[0034] Further, in this embodiment, the CNC on the PC shell base 10 has a secondary injection hole, and a non-transparent colored injection part 50 is fixed by injection molding at the secondary injection hole, and the non-tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com