Electromagnetic wave shielding film material and preparation method thereof

A technology of shielding film and electromagnetic waves, applied in the fields of magnetic field/electric field shielding, electrical components, conductive adhesives, etc., can solve the problems of difficulty in maintaining the shielding function and the film is easy to break, and achieve excellent electromagnetic wave shielding performance and excellent bonding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

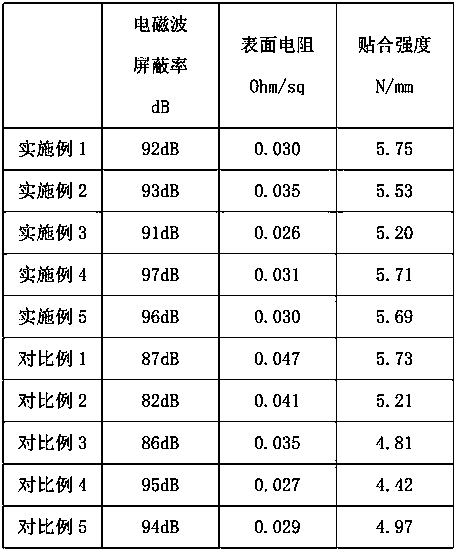

Examples

Embodiment 1

[0038] An electromagnetic wave shielding film material is characterized in that a layer of 5.5 micron matte black resin is coated on one side of the copper foil, and a layer of 15 micron anisotropic conductive adhesive layer is coated on the other side, and the outer layer of the matte black resin is coated with One layer of PET protective layer, plus a layer of PET release film on the outer layer of the anisotropic conductive adhesive layer; the frosted black resin is fully processed by adding 2.5 micron dummy paddles to the oily black resin with a solid content of 25%. Prepared by stirring until the viscosity is 25-26 seconds; the shown anisotropic conductive adhesive layer includes acrylic pressure-sensitive adhesive, isocyanate hardener, melamine hardener, and conductive copper powder, wherein the molecular weight of the acrylic pressure-sensitive adhesive is 750,000, solid The content is 40%, and the conductive copper powder is CoO with a particle size of 6.5 microns and m...

Embodiment 2

[0044] An electromagnetic wave shielding film material, characterized in that a layer of 5-micron matte black resin is coated on one side of the copper foil, and a layer of 12-micron anisotropic conductive adhesive layer is coated on the other side, and the outer layer of the matte black resin is coated with One layer of PET protective layer, plus a layer of PET release film on the outer layer of the anisotropic conductive adhesive layer; the frosted black resin is fully processed by adding 2.5 micron dummy paddles to the oily black resin with a solid content of 25%. Prepared by stirring until the viscosity is 25-26 seconds; the shown anisotropic conductive adhesive layer includes acrylic pressure-sensitive adhesive, isocyanate hardener, melamine hardener, conductive copper powder, wherein the molecular weight of the acrylic pressure-sensitive adhesive is 800,000, solid The content is 40%, and the conductive copper powder is CoO with a particle size of 5.5 microns and more than...

Embodiment 3

[0050] An electromagnetic wave shielding film material, which is characterized in that a layer of 6-micron matte black resin is coated on one side of the copper foil, and a layer of 10-micron anisotropic conductive adhesive layer is coated on the other side, and the outer layer of the matte black resin is coated with One layer of PET protective layer, plus a layer of PET release film on the outer layer of the anisotropic conductive adhesive layer; the frosted black resin is fully prepared by adding 3 micron dummy paddles to the oily black resin with a solid content of 25%. Prepared by stirring until the viscosity is 25-26 seconds; the shown anisotropic conductive adhesive layer includes acrylic pressure-sensitive adhesive, isocyanate hardener, melamine hardener, and conductive copper powder, wherein the molecular weight of the acrylic pressure-sensitive adhesive is 700,000, solid The content is 40%, and the conductive copper powder is CoO with a particle size of 7 microns or mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com