An automatic water spray mop

A mop and automatic technology, applied in the field of mop, can solve the problems of saving time and labor, and achieve the effect of simple operation and uniform water spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes the embodiments in further detail to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

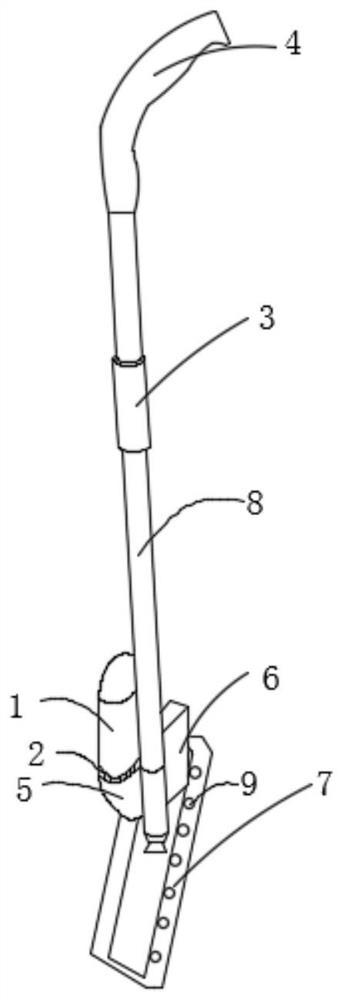

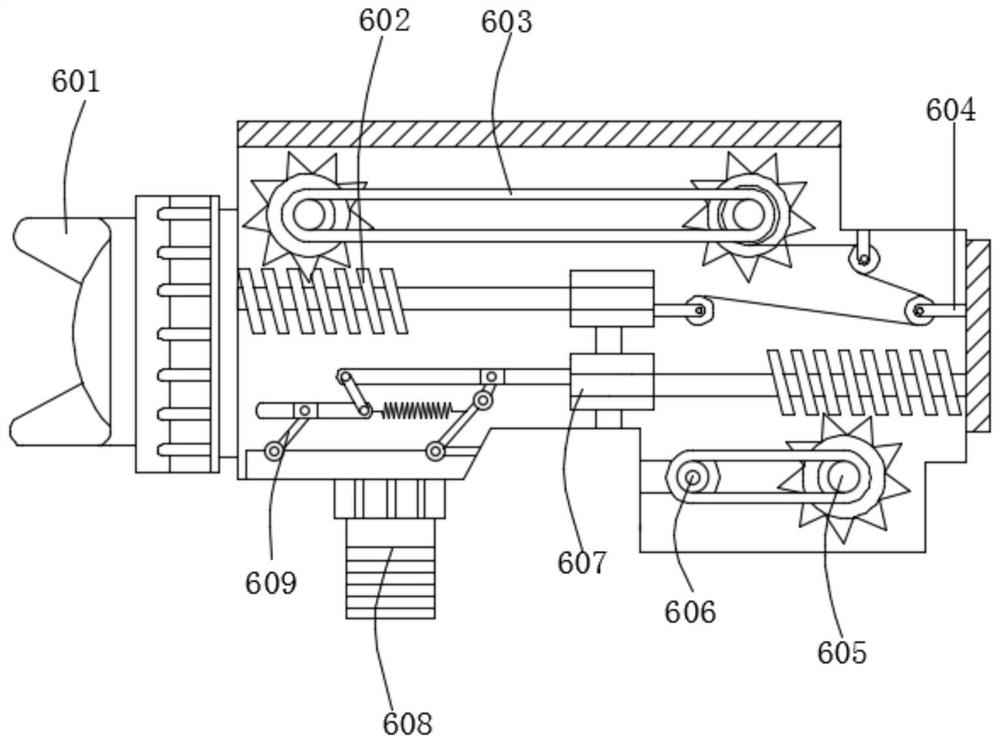

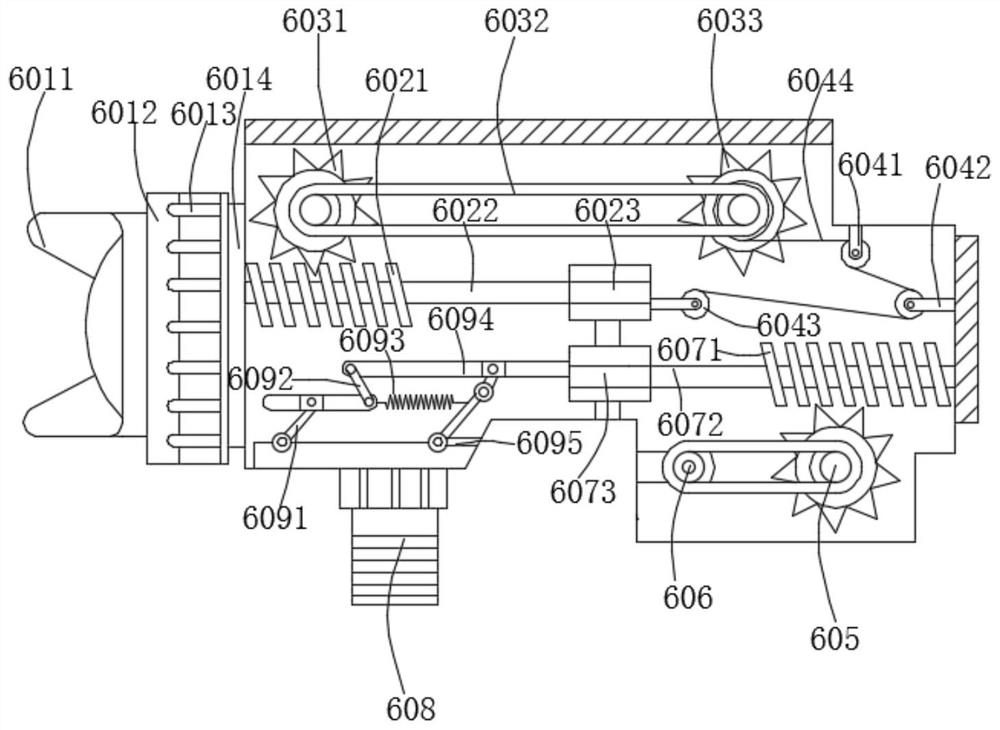

[0021] Such as Figure 1-3 , an automatic water spray mop, its structure includes: water tank, 1, water tank base 2, anti-slip ring 3, handle 4, adjustable nozzle 5, water spray mechanism 6, mop head 7, handle bar 8 and pressure The trigger 9 and the water spray mechanism 6 are composed of a fixed sleeve 601, a first transmission shaft 602, a gear transmission mechanism 603, a pulley transmission assembly 604, a driving wheel 605, a driven wheel 606, a second transmission shaft 607, a connecting mechanism 608, and a linkage mechanism 609. , the water spray mechanism 6 is mechanically connected with the pressure trigger 9, and cooperates with the water filling tank 1 and the water filling tank base 2;

[0022] The fixed sleeve 601 is horizontally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com