Combined putting green for water-borne golf club swinging exercise

A golf ball and green technology, which is applied to the field of combined greens for water golf swing practice, can solve the problems of uneven turf deployment and high price, and achieve the effects of easy storage and transportation, high production efficiency, high strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

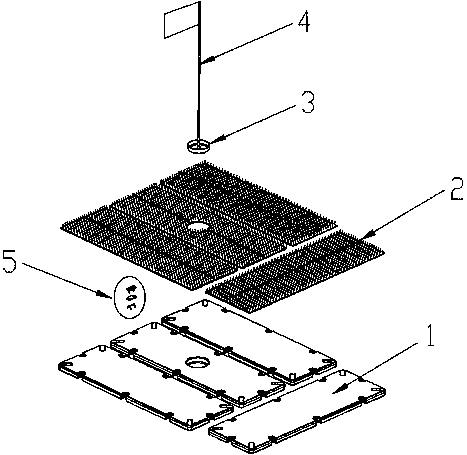

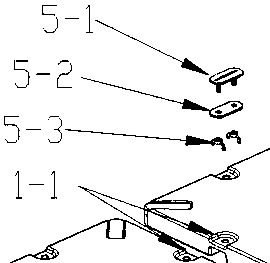

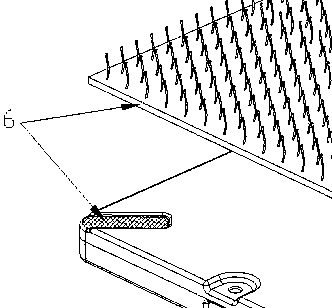

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the combination green for golf swing practice on water includes a blow-molded base plate 1, turf 2, hole cup 3, target flag 4, locking member 5, Velcro 6, and connections between the blow-molded base plate 1 It is the first matching mechanism, and the connection between the blow molding bottom plate 1 and the turf 2 is the second matching mechanism. The first matching mechanism includes a U-shaped block 5-1, a flat washer 5-2, and a wing nut 5-3. , connect the two boards in the groove 1-1 corresponding to the blow molding base plate 1 through the U-shaped block 5-1 and the flat gasket 5-2, and then lock the wing nut 5-3 into the U-shaped block 5- 1 and locked, and the blow molding bottom plates are connected by three U-shaped blocks 5-1; the second matching mechanism is set at the four corners of the blow molding bottom plate and the turf, and the second matching mechanism is a quick connection method , b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com