Combined wall structure and construction method thereof

A wall structure and combined technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of affecting the construction progress, inconvenient construction, and low strength of the wall structure, so as to save construction time and facilitate installation , Increase the effect of the effective contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The application will be described in further detail below in conjunction with the accompanying drawings.

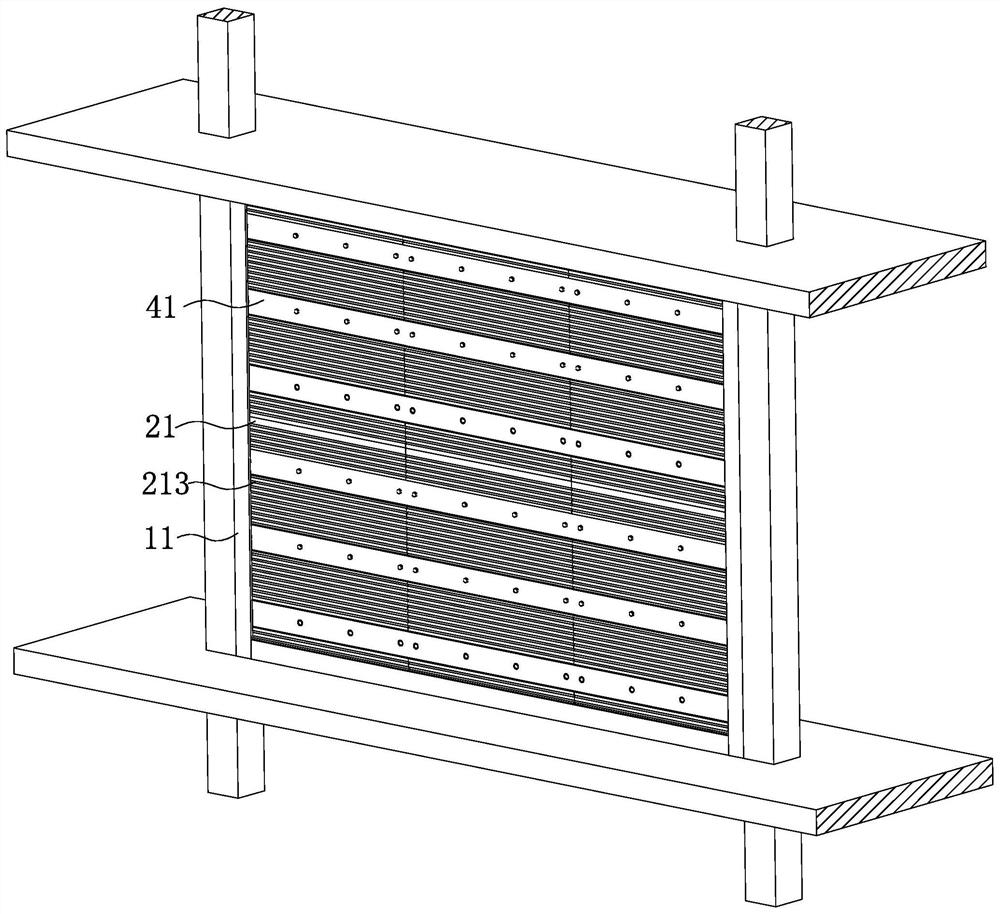

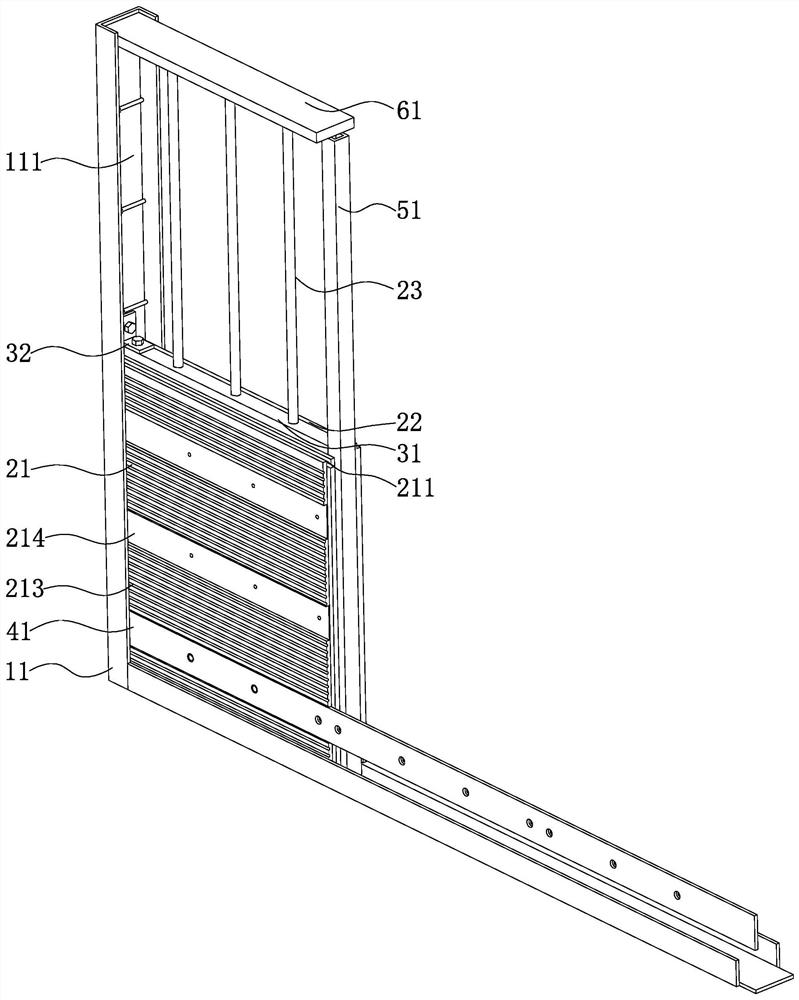

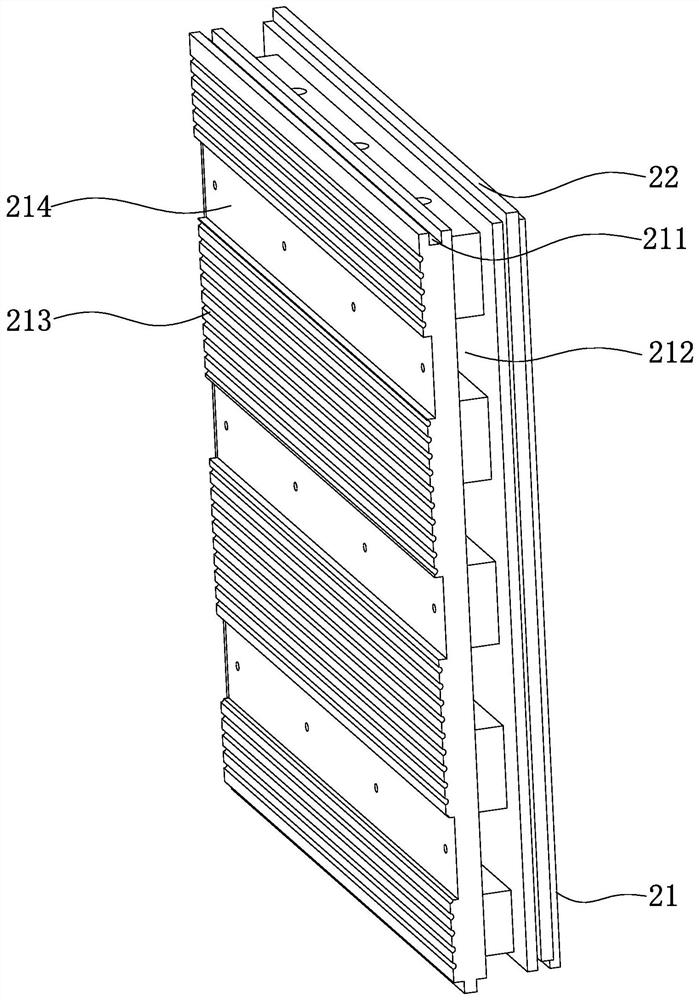

[0045] refer to figure 1 and figure 2 , the embodiment of the present application discloses a combined wall structure, which mainly includes a steel member 11, a prefabricated wall panel 21, a secondary keel 31, a connecting plate 41, a main keel 51 and an edge cover 61.

[0046] refer to figure 2 , the steel member 11 can be made of channel steel. It can be understood that the channel steel is welded by a bottom plate and two side plates vertically connected to the bottom plate. In the embodiment of the application, the surface of the channel steel bottom plate and the building frame The surface of the main body is abutted, and then the steel member 11 is fixed and installed with expansion bolts. The steel member 11 is also provided with a limit groove 111 along the length direction. Get final product in the groove 111.

[0047] refer to figure 2 and ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com