Control device for machine tool performing oscillation cutting

一种控制装置、机床的技术,应用在自动控制装置、喂食装置、程序控制等方向,能够解决无法解决切割工具超过加工停止位置等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the following drawings, the same reference signs are attached to the same components. For easy understanding, the scales of these drawings are appropriately changed. In addition, the form shown in drawing is an example for implementing this invention, and this invention is not limited to the form of illustration.

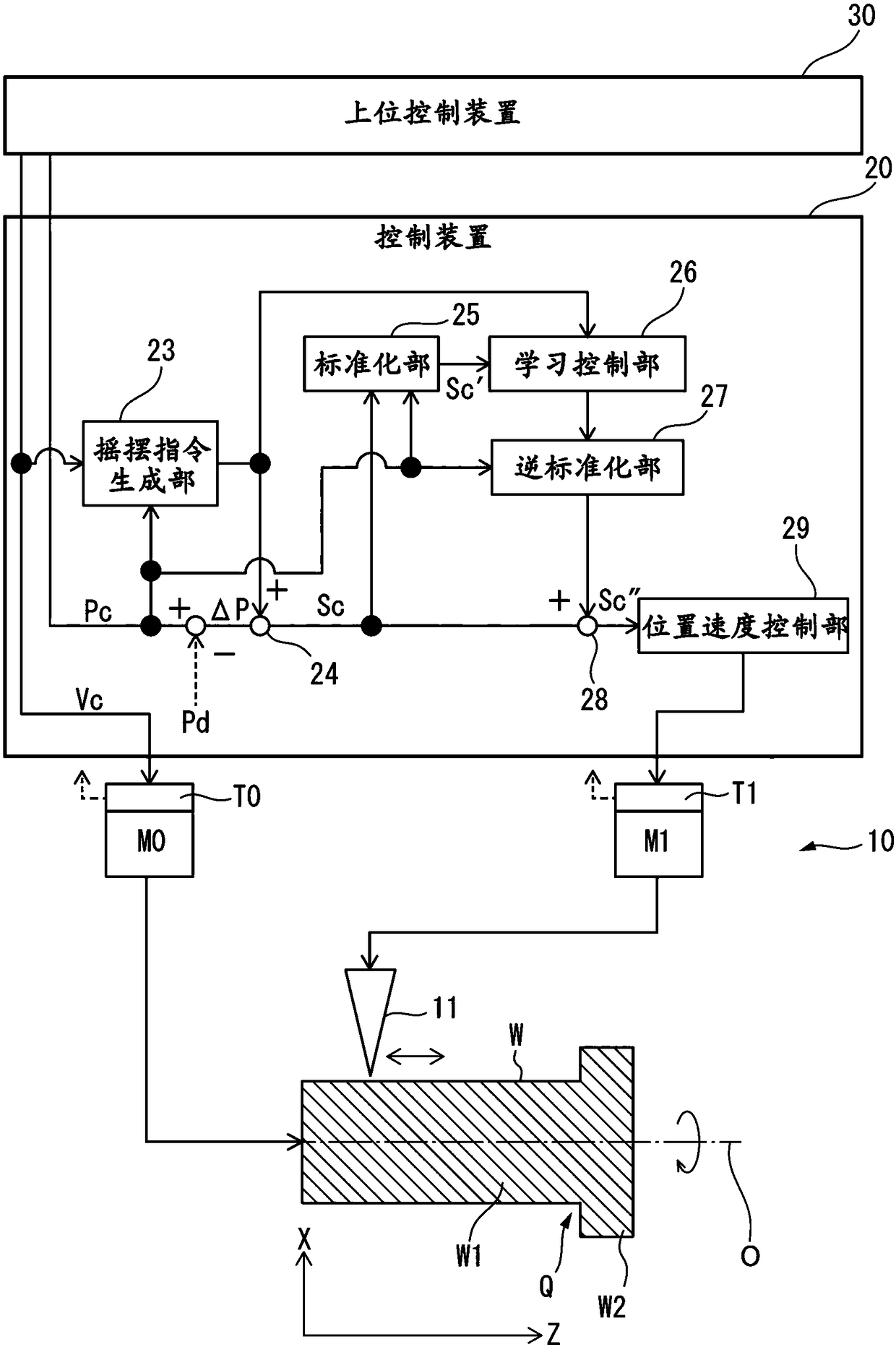

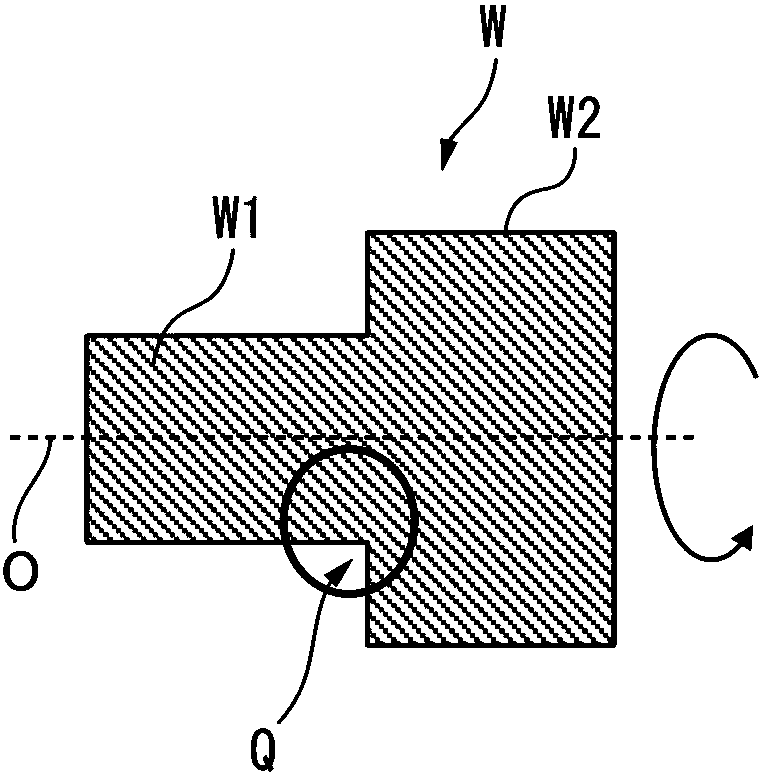

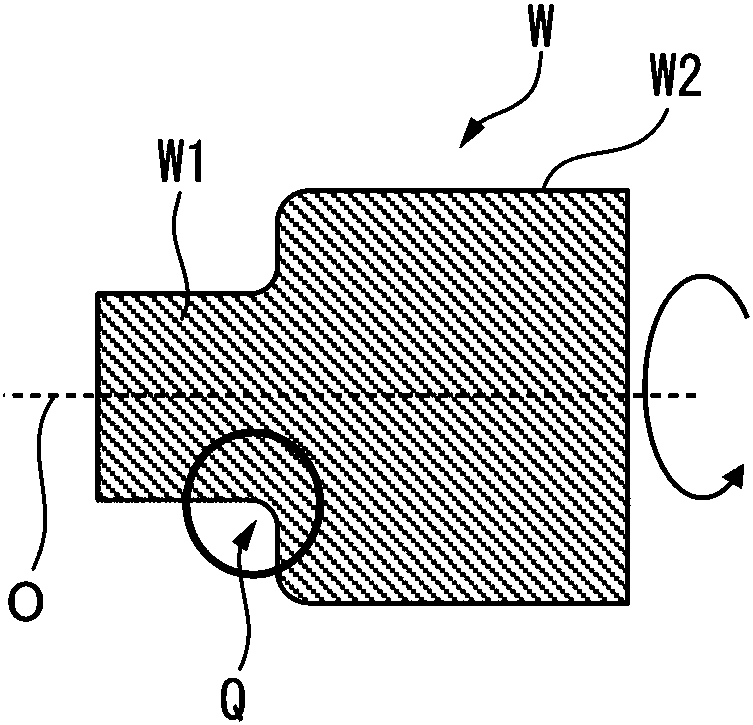

[0020] figure 1 It is a system diagram including the control device according to the first embodiment. Such as figure 1 As shown, the system 1 includes: a machine tool 10 , a control device 20 for controlling the machine tool 10 , and a host control device 30 connected to the control device 20 . The machine tool 10 has a tool 11 which cuts an outer or inner peripheral surface of a workpiece W which is at least partially rotationally symmetrical about an axis of rotation O. In addition, in figure 1 Among others, the axis of rotation of the workpiece W i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com