Concrete manufacturing automatic production device

An automatic production and concrete technology, which is applied in clay preparation devices, mixing operation control, mixing plants, etc., can solve the problems of difficulty in ensuring the continuity of raw material mixing, low mixing efficiency of raw materials, and slow process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

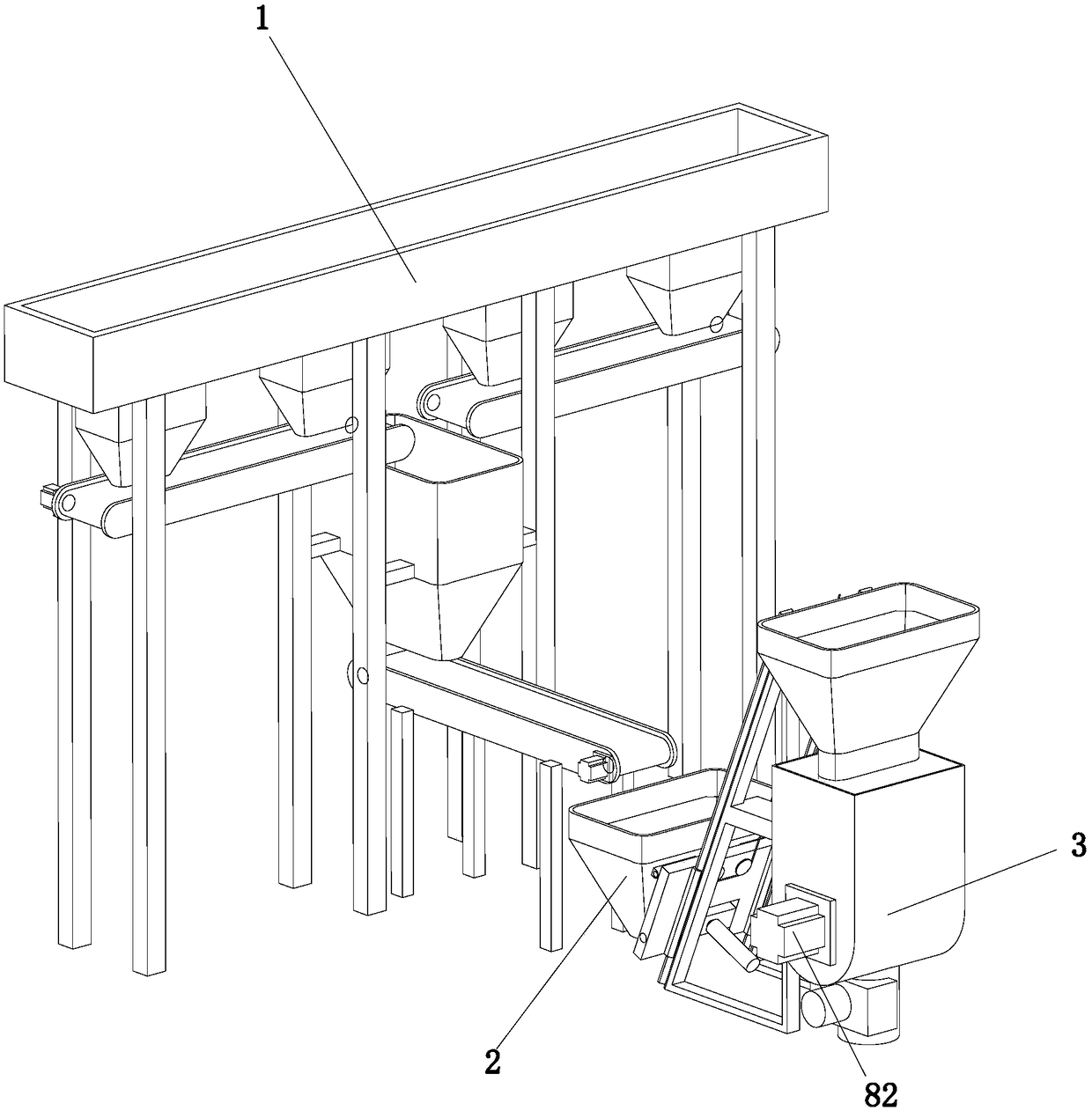

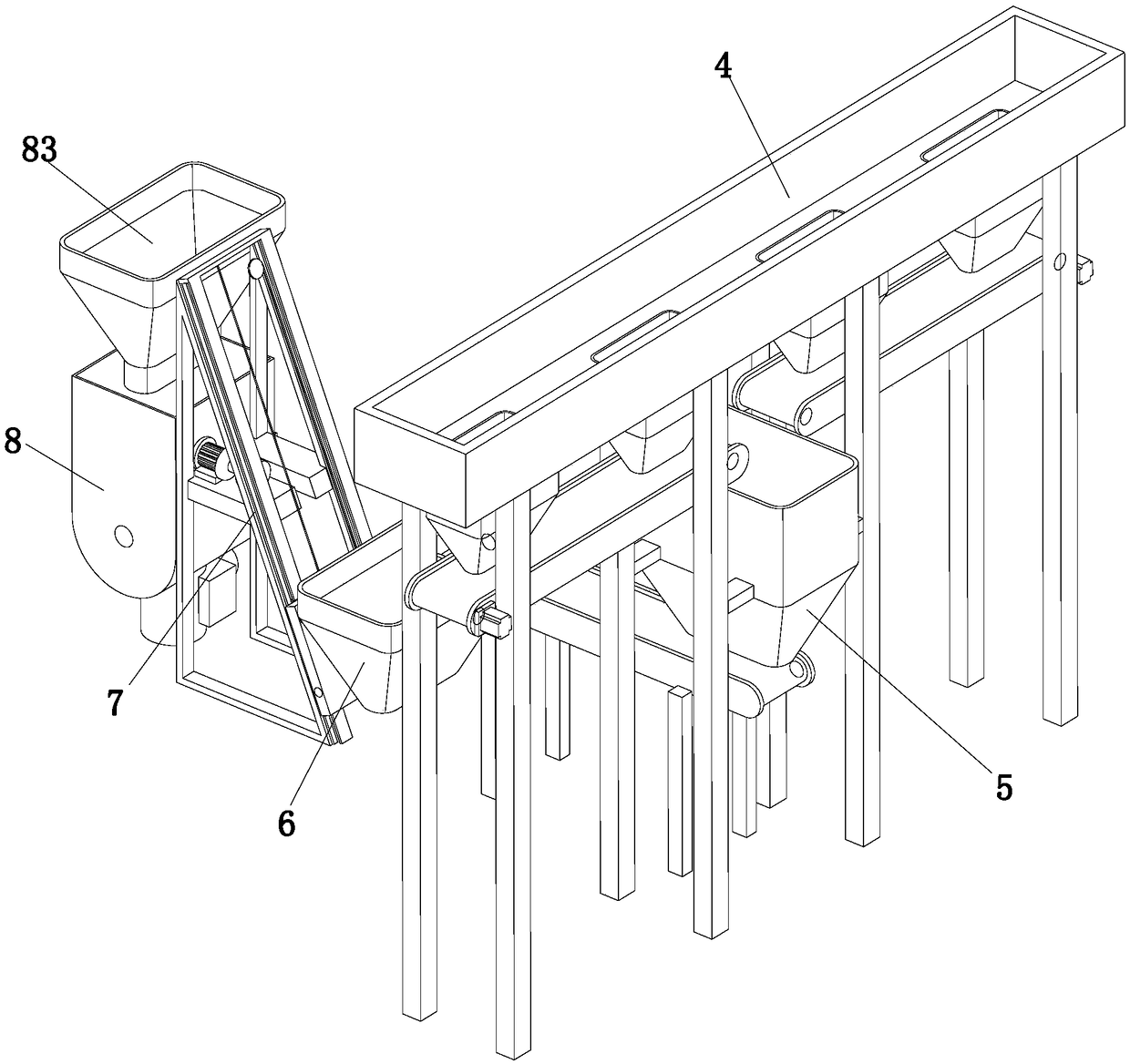

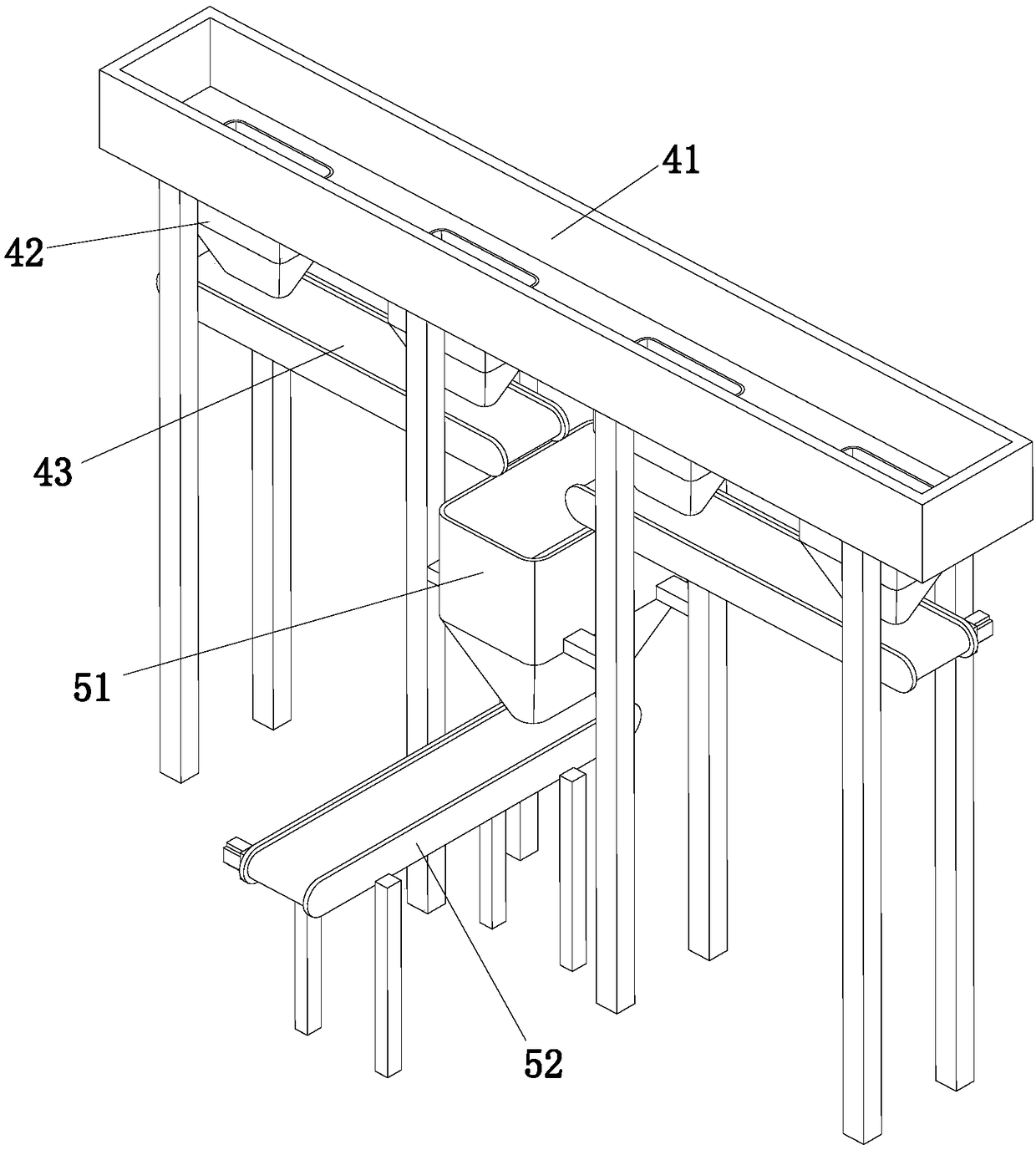

[0020] refer to Figure 1 to Figure 5 The shown automatic production device for concrete production includes an automatic feeding device 1, an automatic feeding device 2, a stirring device 3 and a control device, and the automatic feeding device 1 includes a storage component for storing raw materials to be mixed 4 and a transfer assembly 5 for raw material transition transfer, the automatic feeding device 2 includes a lifting hopper 6 and a driving assembly 7 for driving the lifting hopper 6 up and down, the stirring device 3 includes a stirring assembly 8 and is arranged on The feeding hopper 83 directly above the stirring assembly 8, the control device includes a controller and a sensor assembly electrically connected to the controller, the lifting hopper 6 is slidably matched with the drive assembly 7 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com