Three-phase power supplying and collecting device for maglev train

A technology for maglev trains and current collectors, which is applied to current collectors, power collectors, motor vehicles, etc. It can solve the problems of affecting current collection, affecting contact performance, and not being suitable for high-speed occasions, so as to save investment, improve cost performance, and be easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

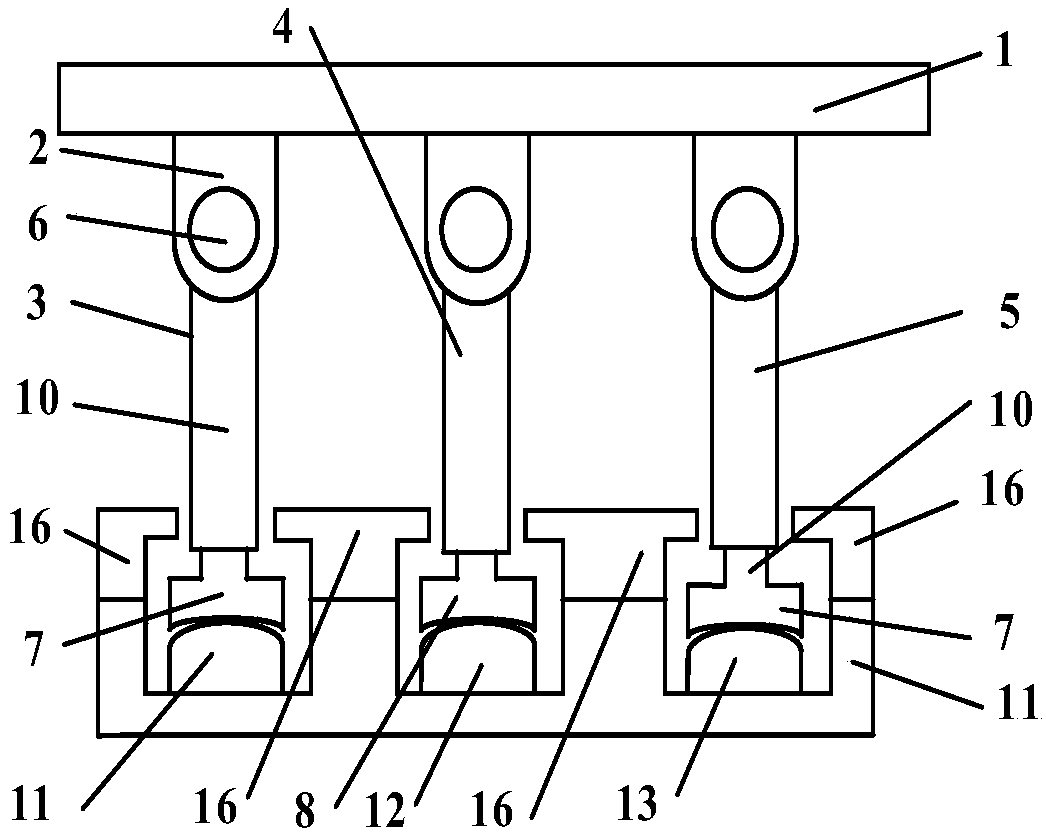

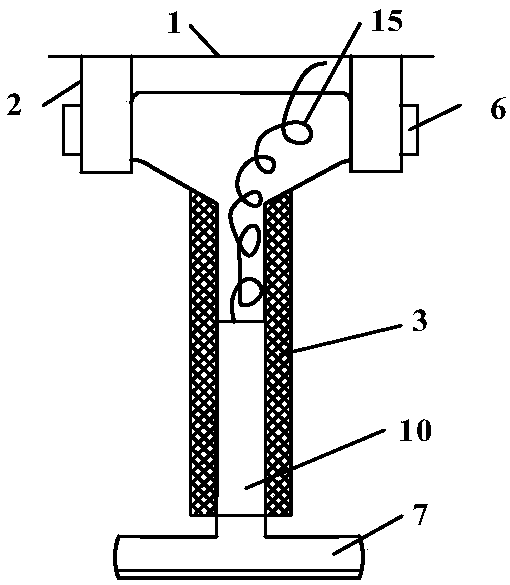

[0022] figure 1 As shown, a specific embodiment of the present invention is as follows: a crossbeam 1 is arranged in the middle of the bogie of a maglev train, and the lower surface of the crossbeam 1 is divided into three sets of longitudinal bearing blocks 2 in the left, middle and right sides, which are matched with it. There are three left, middle and right insulating bushings, that is, left insulating bushing 3, middle insulating bushing 4 and right insulating bushing 5. The insulating bushings are in a T-shaped structure, and the two ends of the horizontal part are shaft 6 structures, which pass through the bearing It is fixed with the bearing seat 2, and its vertical part is a hollow tubular structure; matching with the left, middle and right insulating sleeves, three collector shoes are set, namely the left collector shoe 7, the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com