Washing machine

A washing machine and clothing technology, applied in the field of washing machines, can solve the problems of unsatisfactory local stubborn stains, easy vibration and drop of stains, limited cleaning effect, etc., to achieve enhanced ultrasonic effect, thorough removal of stains, and good resonance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

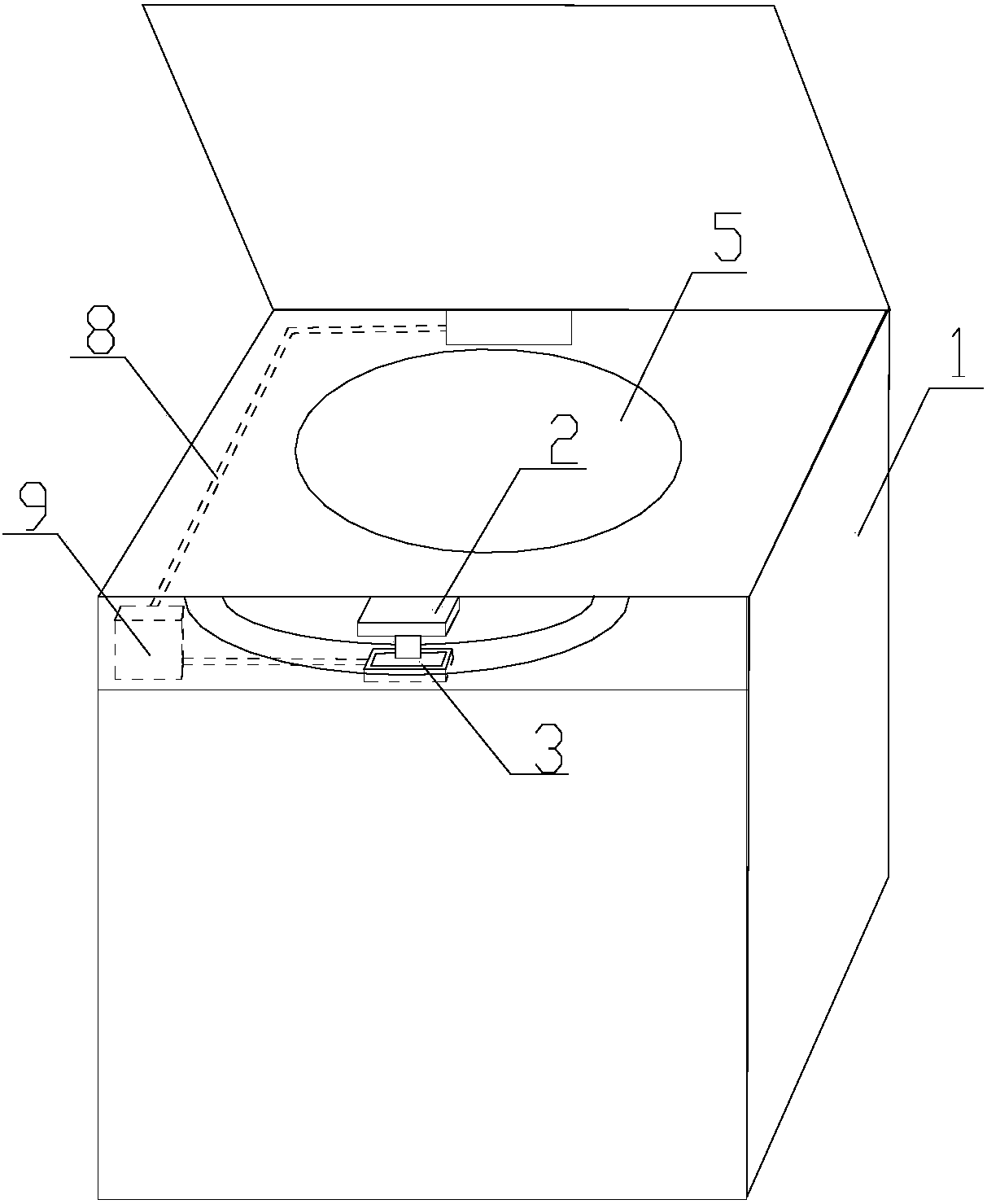

[0042] Such as Figure 1 to Figure 5 As shown, the present embodiment provides a washing machine, comprising:

[0043] A housing 1, the housing 1 is provided with a washing bucket 5;

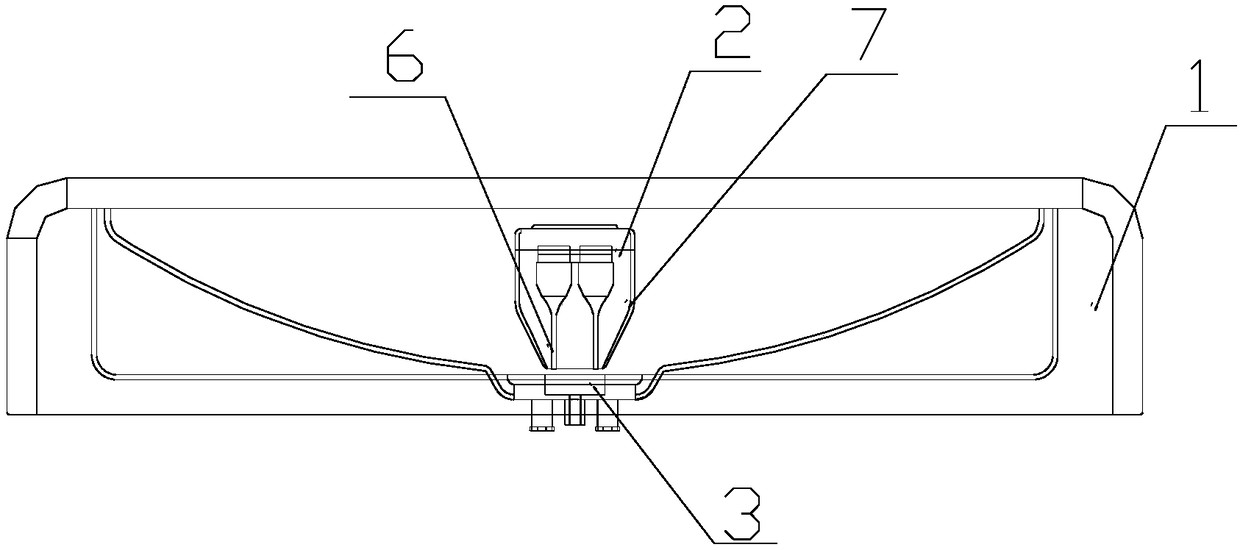

[0044] A cleaning tank 3 for holding the washing liquid 12, the cleaning tank 3 is arranged on the housing 1;

[0045]Ultrasonic generating device 2, described ultrasonic generating device 2 is arranged on the top of the cleaning tank 3 and connected with the housing 1, the ultrasonic vibration end of the ultrasonic generating device 2 faces the cleaning tank, and the laundry 4 is placed on the ultrasonic generating device 2 and the cleaning tank After 3 minutes, the ultrasonic vibrating end of the ultrasonic generator 2 is in partial contact with the laundry 4, and the ultrasonic vibration wave is directly transmitted to the laundry 4 soaked in the washing liquid 12 for cleaning.

[0046] The washing bucket 5 of the washing machine of the present embodiment is used to clean the whole, relativ...

Embodiment 2

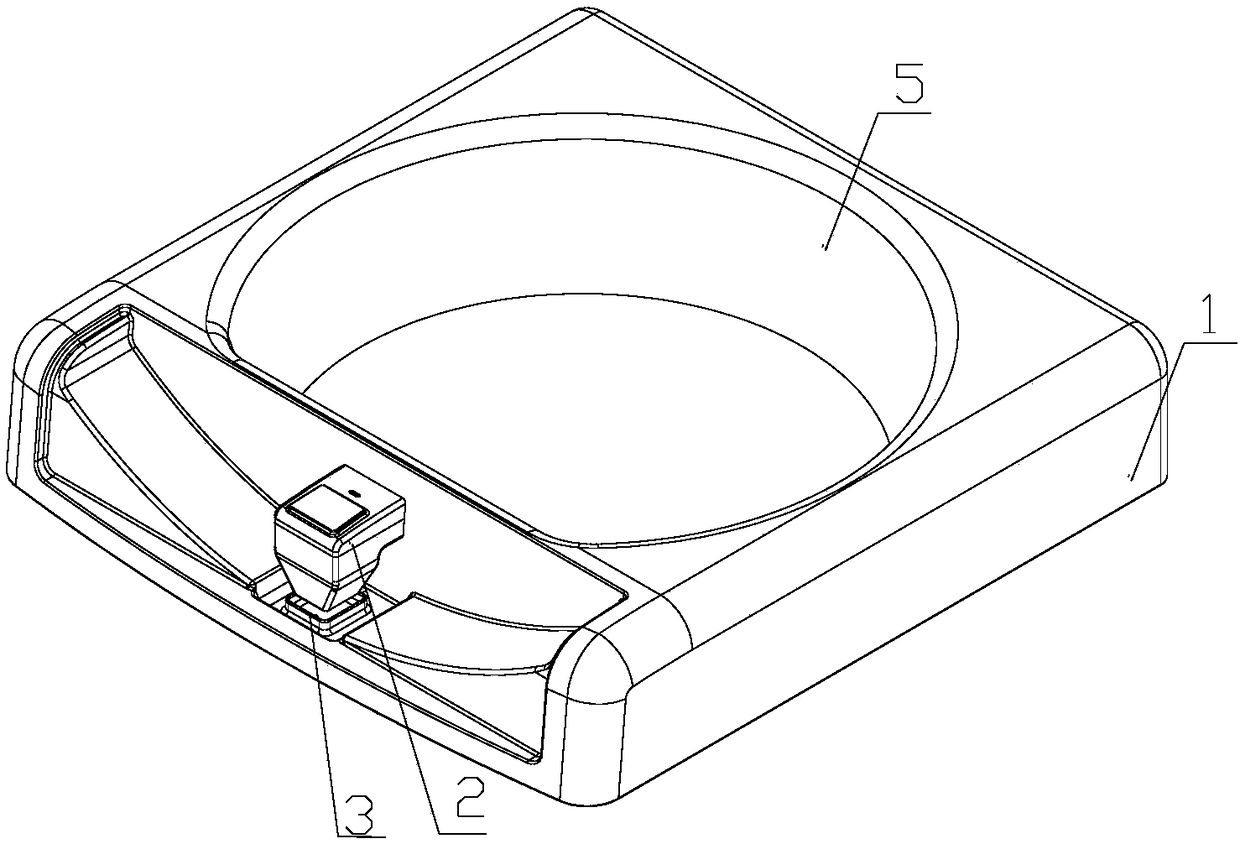

[0062] This embodiment is a further limitation of Embodiment 1. The shell 1 at the top and front end of the washing machine in this embodiment is provided with a cavity to form a cleaning tank 3, or the cleaning tank 3 is a separate piece placed in the cavity. The position of the cleaning tank 3 is lower than the height of the shells 1 of the washing machines on both sides, and the heights of the shells 1 of the washing machines on both sides gradually rise, and the transition is smooth, forming a smooth arc, which will not scratch the clothes , It is also beneficial for water to flow in the cleaning tank 3 . When the wet laundry 4 is placed outside the washing tank 3, due to the height difference, the liquid will flow into the washing tank 3 without turbulent flow, so as to prevent the liquid from flowing into the washing machine from the influence of the gap.

[0063] The ultrasonic generating device 2 is arranged above the cleaning tank 3, and the rear side of the ultrasoni...

Embodiment 3

[0069] Such as figure 1 As shown, this embodiment is a further limitation of Embodiment 1 or Embodiment 2. The washing machine of this embodiment is provided with a main water inlet pipeline for feeding water into the washing tub 5 of the washing machine and feeding the detergent box of the washing machine. Enter water in the middle, and the detergent in the detergent box, the softening agent etc. are brought in the washing bucket 5, and the whole piece of clothing is cleaned. The main water inlet pipeline is arranged on the upper part of the washing machine.

[0070] The housing 1 of the top front end of the washing machine of the present embodiment is provided with a cleaning tank 3 and an ultrasonic generator 2, and is also provided with a cleaning tank water inlet pipeline 8, and the upstream of the cleaning tank water inlet pipeline 8 is connected with the main water inlet pipeline of the washing machine. The downstream communicates with the cleaning tank 3 . The cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com