Washing machine and automatic put-in system of washing machine

A technology for automatic delivery and washing machine, applied in the field of washing machines, can solve problems such as troublesome use, inability to realize, and inconvenient operation of users, and achieve the effects of not easy to leak, improve efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

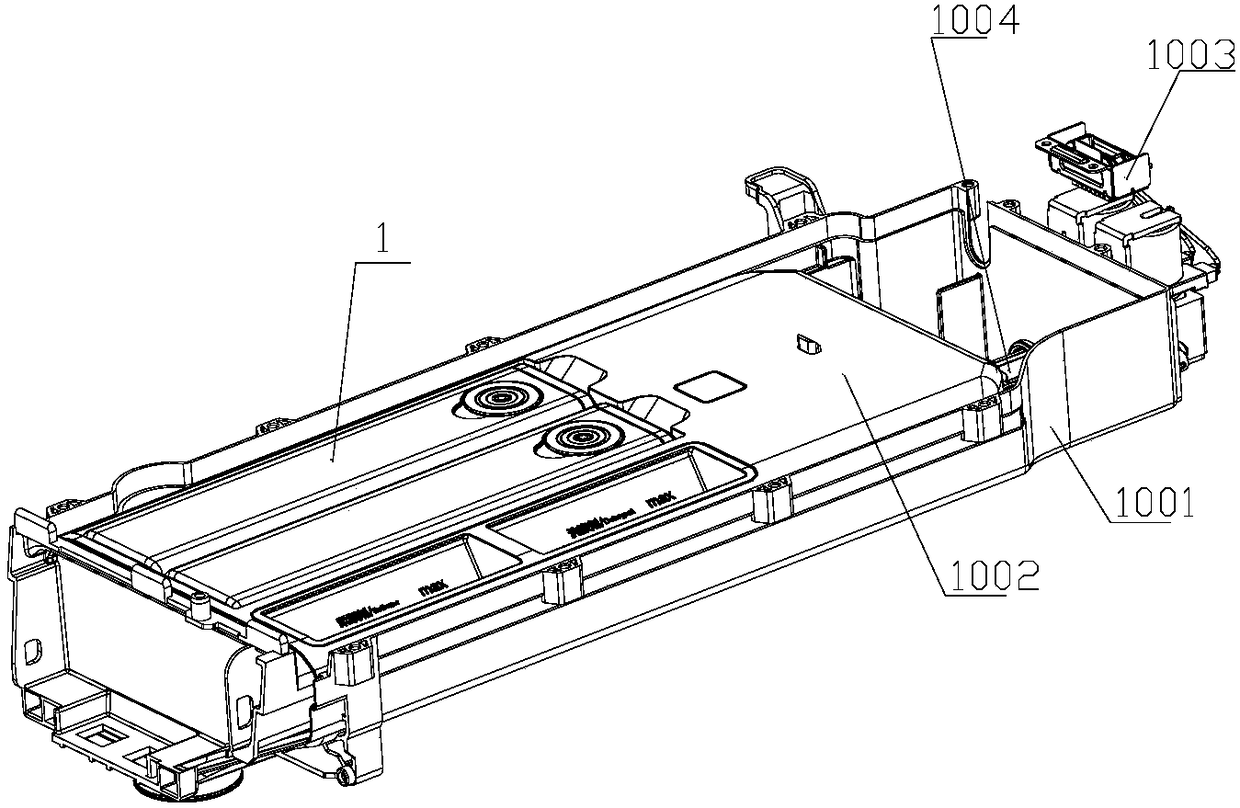

[0061] Such as Figure 1-22 As shown, this embodiment provides an automatic washing machine feeding system, including a water box 1001, the water box 1001 has a water outlet 1004 connected with the washing tub of the washing machine, and is integrated with a main water inlet pipeline and a detergent feeding pipeline, and also includes :

[0062] The distribution box 1002 is arranged in the water box 1001, and the distribution box 1002 is provided with at least one installation cavity for placing the washing additive box 1;

[0063] The washing additive box 1, the washing additive box 1 is a closed box structure with a cavity inside for holding the washing additive, and the washing additive box 1 is provided with a one-way air-permeable structure 2 and a liquid outlet 12, and the washing additive When the box 1 is installed in the installation cavity and communicates with the detergent injection pipeline, the liquid outlet 12 is opened; when the detergent additive box 1 is dis...

Embodiment 2

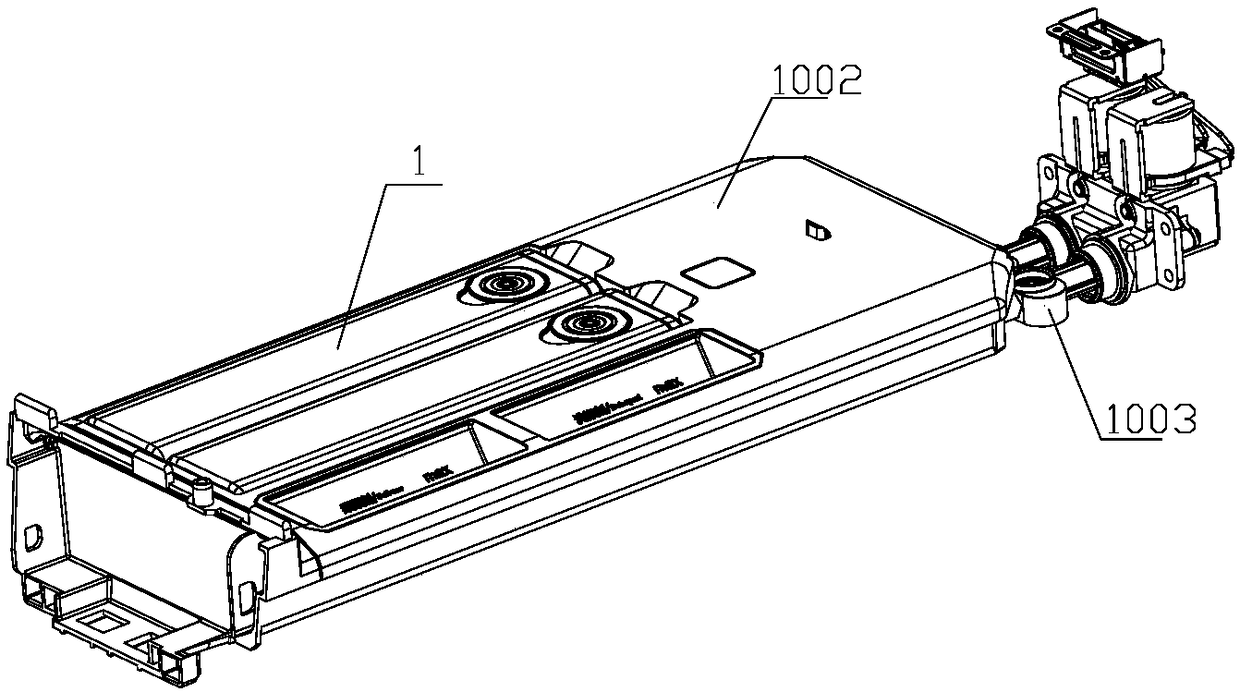

[0074] Such as Figure 7-Figure 14 As shown, this embodiment is a further limitation of Embodiment 1. This embodiment provides an automatic feeding system for washing machines, wherein the detergent additive box 1 includes a closed box body with a cavity inside, and the box body is provided with There is a liquid outlet, which is used to communicate with the box body and the switching mechanism 1003. The box body is provided with a one-way air-permeable structure, which is used to balance the air pressure inside and outside the detergent additive box 1; Liquid device, the detergent additive is installed in the cavity inside the box body, enters the switching mechanism 1003 from the liquid outlet through the liquid outlet device, enters the detergent injection pipeline under the action of the negative pressure extraction mechanism, and flows through the The water outlet of the water box 1001 enters the washing bucket of the washing machine to assist washing.

[0075] A plurali...

Embodiment 3

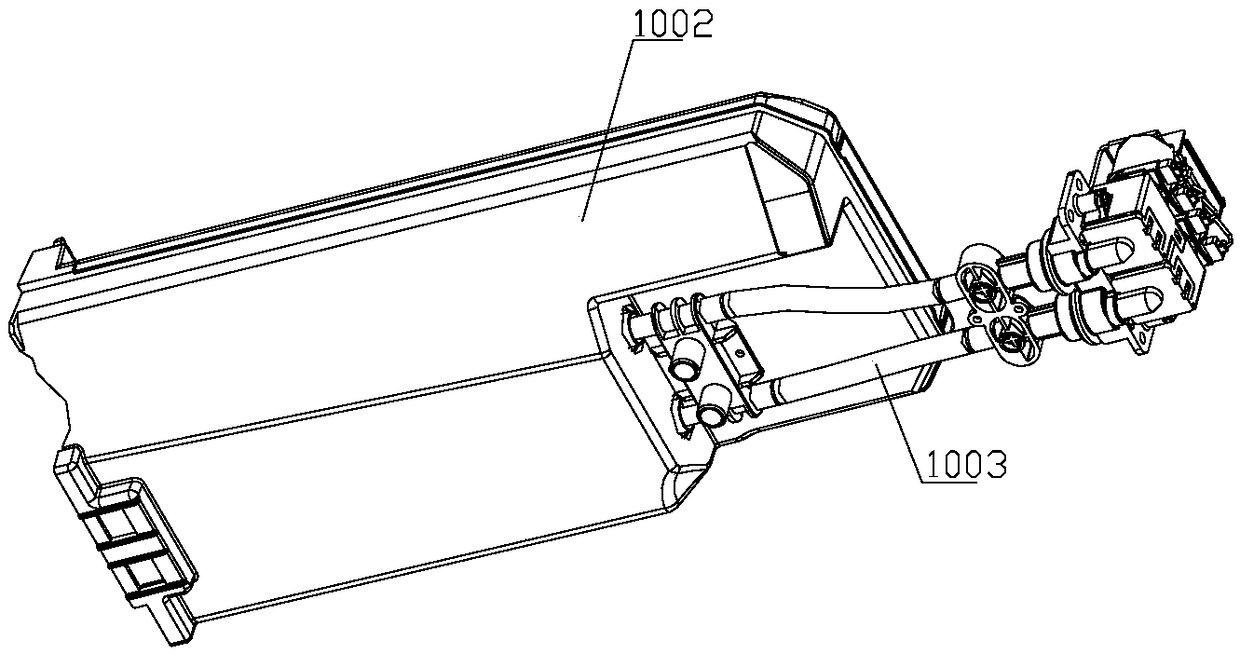

[0088] This embodiment is a further limitation of Embodiment 1. This embodiment provides a washing machine automatic feeding system, wherein the washing additive box 1 includes a closed box body with a cavity inside, and a liquid outlet is provided on the box body. Port 12, the liquid outlet 12 is used to communicate with the box body and the detergent injection pipeline. The box body is provided with a one-way air-permeable structure to balance the air pressure inside and outside the detergent additive box; the detergent additive box is provided with a liquid outlet The detergent additive is installed in the cavity inside the box body, and under the action of the negative pressure extraction mechanism, it enters the detergent injection pipeline from the liquid outlet through the liquid outlet device, thereby entering the main water inlet pipeline or other pipelines into the wash tub.

[0089] Such as Figure 15-17 As shown, in this embodiment, the detergent additive box 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com