Motor and Dual Mass Flywheel

A dual-mass flywheel and flywheel technology, applied in flywheels and other directions, can solve problems such as low engine speed, resonance impact, damage, etc., and achieve the effect of meeting anti-resonance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

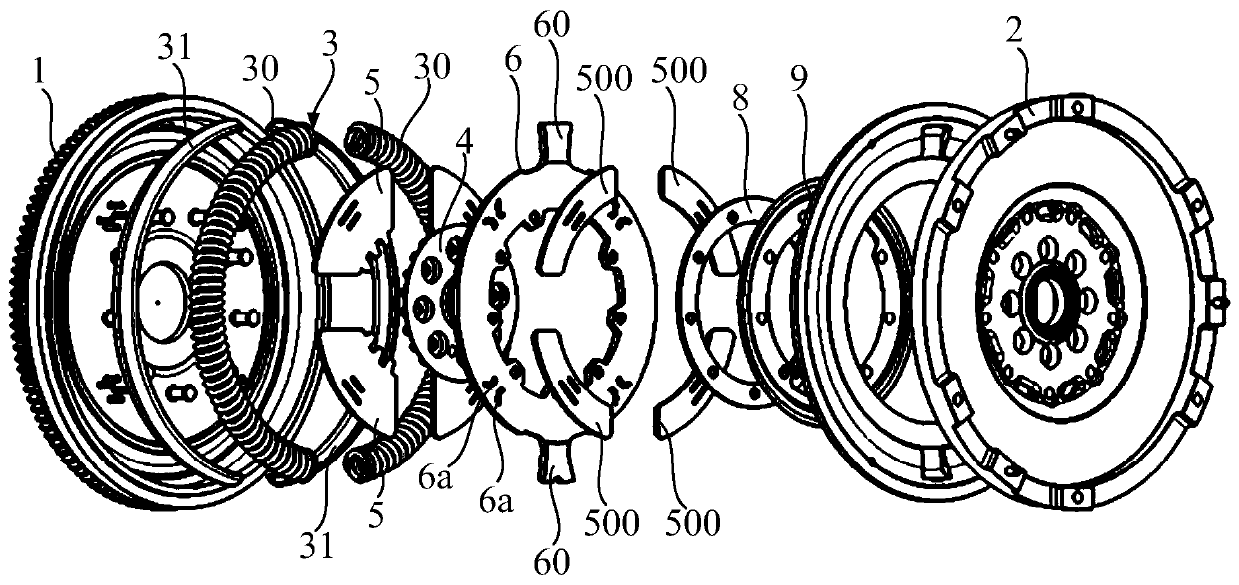

[0048] A car includes an engine, a gearbox, and a dual-mass flywheel connected between the engine and the gearbox. The dual-mass flywheel can transmit the output torque of the engine to the gearbox. refer to figure 1 The dual-mass flywheel can include a main flywheel 1 and an auxiliary flywheel 2 arranged in sequence along the axial direction, and an elastic damping mechanism 3 and a clutch can be arranged between the main flywheel 1 and the auxiliary flywheel 2, and the elastic damping mechanism 3 can be used in the main flywheel. The flywheel 1 and the auxiliary flywheel 2 are elastically deformed when they rotate relative to each other, so as to achieve the purpose of vibration reduction.

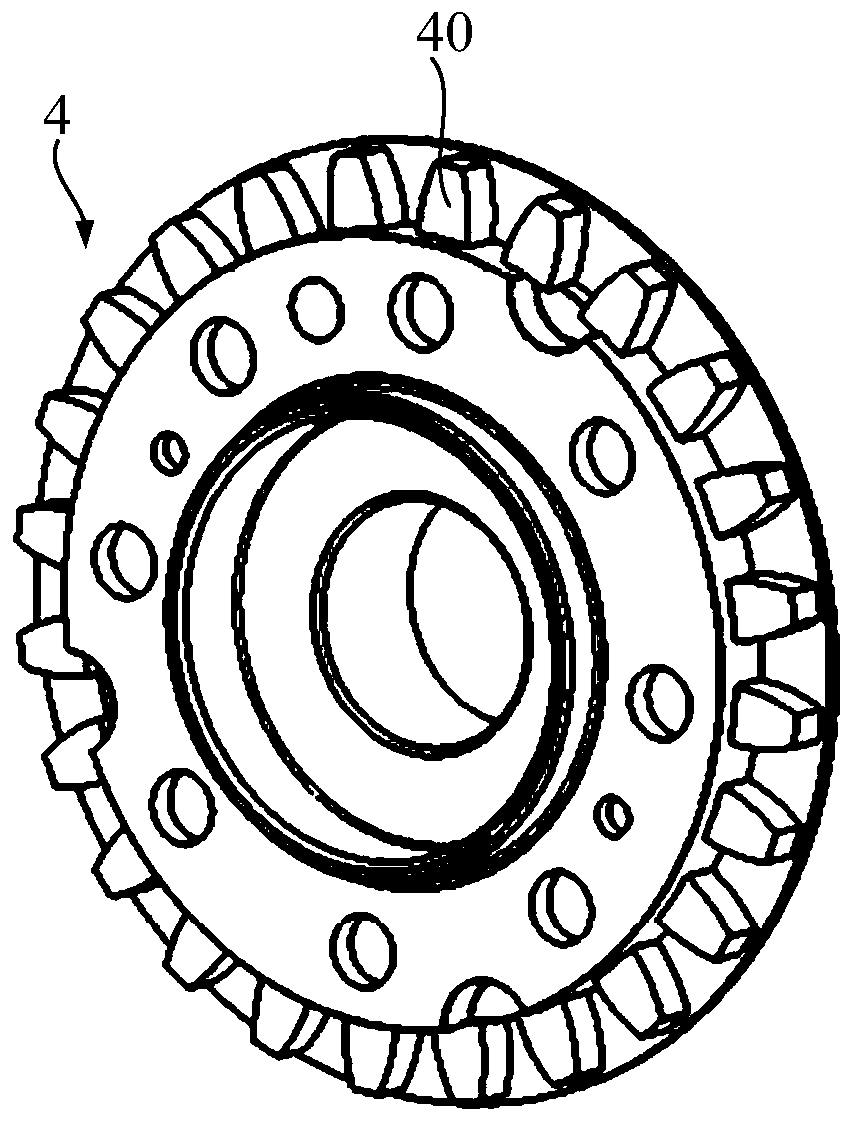

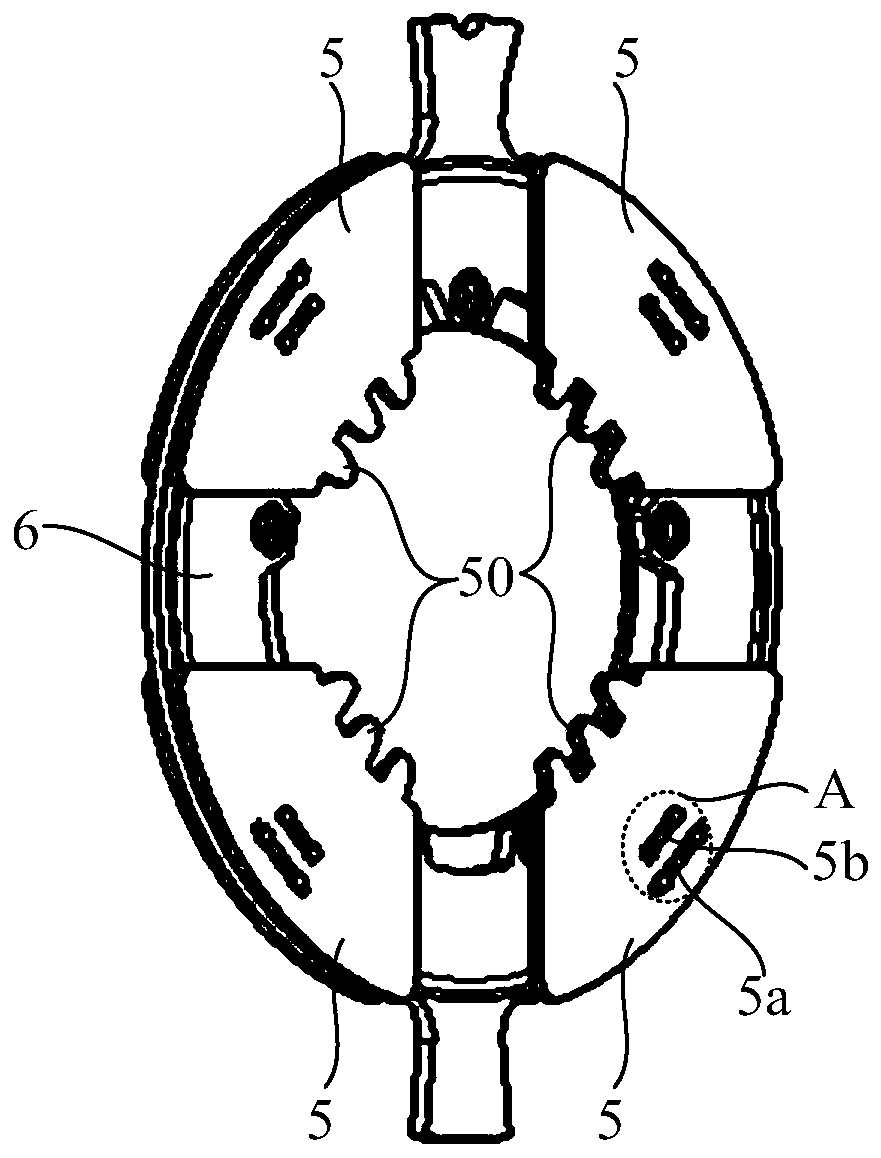

[0049]The clutch part includes a fixed part 4 and a movable part 5, one of the movable part 5 and the fixed part 4 is connected to the main flywheel 1 and the other is connected to the auxiliary flywheel 2, which may include: the fixed part 4 is arranged on the auxiliary flywheel 2 and ...

no. 2 example

[0079] refer to Figure 6 , the movable part 15 can be provided with an insertion part 150, and the fixed part 14 can be provided with a receiving part 14a;

[0080] When the insertion part 150 is not inserted into the receiving part 14a, the fixed part 14 and the movable part 15 can be separated;

[0081] When the insertion part 150 is inserted into the receiving part 14a, the fixed part 14 and the movable part 15 may be combined.

[0082] From separation to combination, there is relative rotation between the fixed part 14 and the movable part 15, the insertion part 150 can first contact the outer peripheral surface of the movable part 15, and slide along the outer peripheral surface to fall into the receiving part 14a, and then the insertion part 150 is blocked by the side wall of the receiving portion 14a, so that the fixed part 14 and the movable part 15 are combined.

[0083] The fixed part 14 has an outer peripheral surface facing the movable part 15 , and the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com