Steam system energy-saving device and method

A steam system and energy-saving device technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as energy loss, unstable temperature and pressure of steam, and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

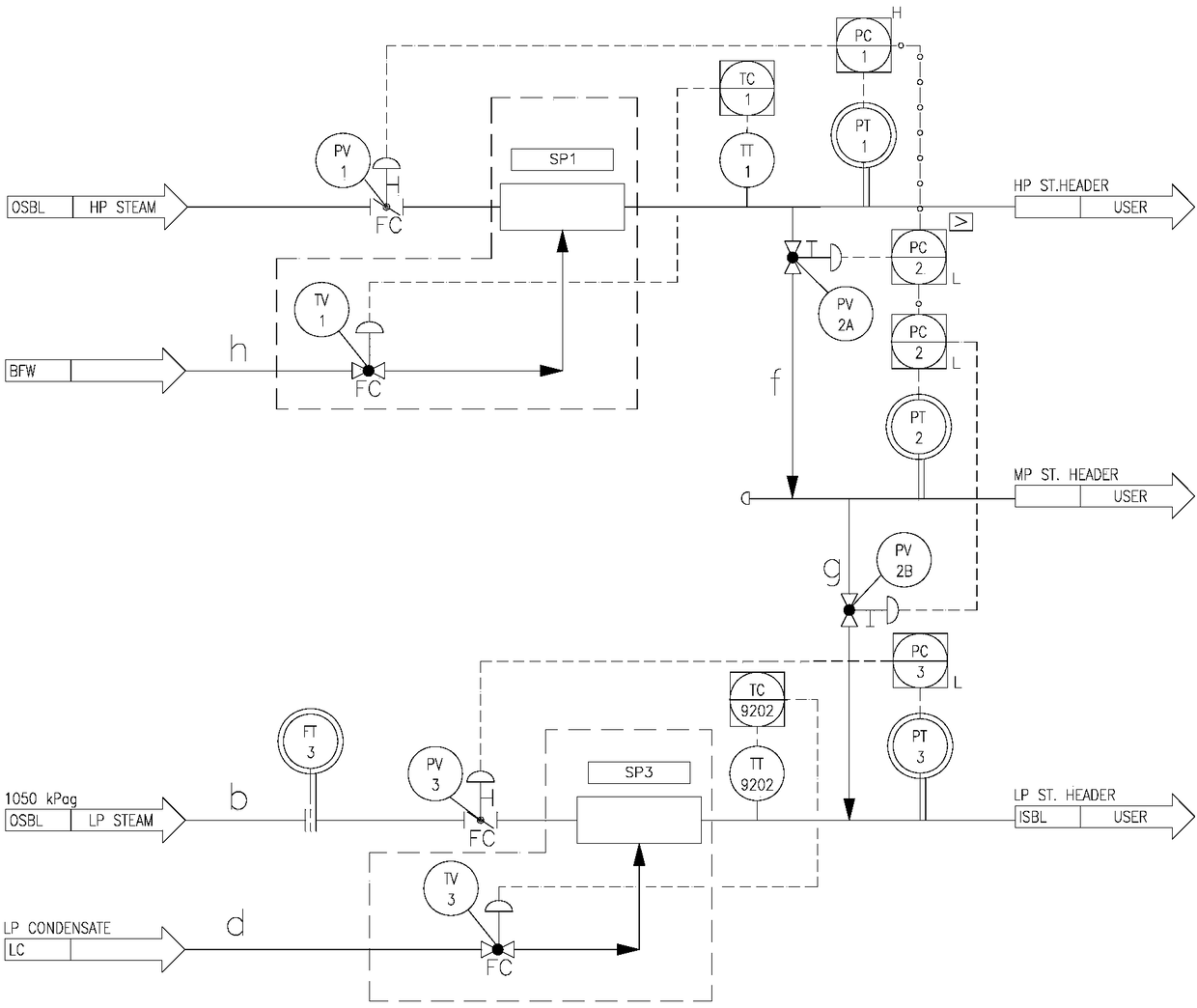

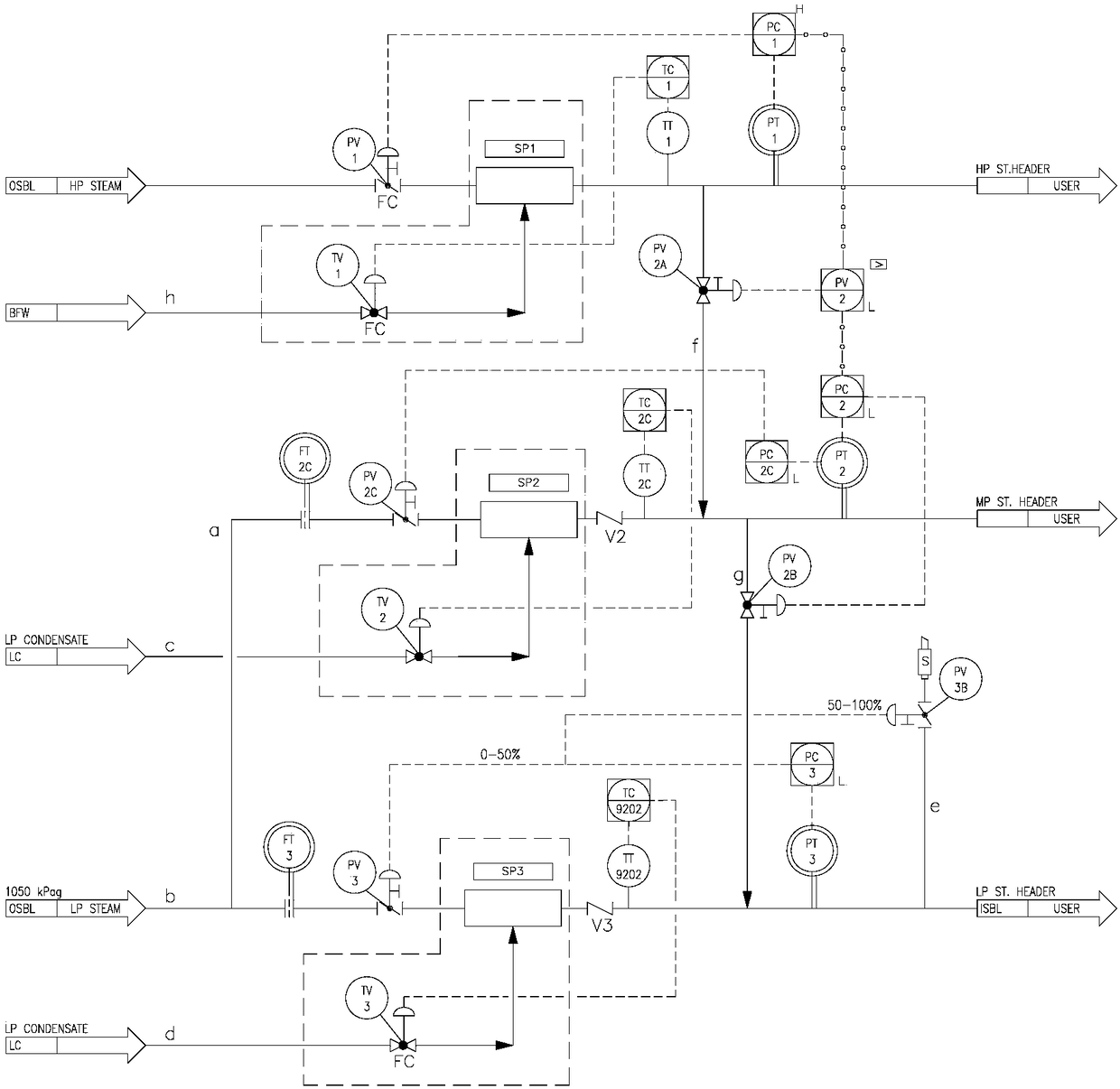

[0044] use as figure 2 For the design scheme shown, the steam conditions provided outside the boundary are as follows:

[0045] Table 1

[0046]

minimum value

normal value

maximum value

design value

High pressure steam pressure, kPag

3100

3200

3500

4200

High pressure steam temperature, ℃

275

280

285

360

Low pressure vapor pressure, kPag

780

1050

1250

1400

Low pressure steam temperature, ℃

200

210

270

320

[0047] The original design high-pressure steam is decompressed to 1000kPag and used as medium-pressure steam.

[0048] The requirements for high, medium and low pressure steam in the industry are shown in Table 2:

[0049] Table 2

[0050]

normal value

High alarm value

low alarm value

maximum value

High pressure steam pipe network pressure, kPag

2100

2300

1900

2400

Medium pressure steam pipe network pressure, kPag

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com