Automatic calibration device for steam generator heat transfer tube eddy current inspection probe and installation method of automatic calibration device

A steam generator and automatic calibration technology, applied in the direction of material magnetic variables, etc., can solve the problems of manual calibration and other problems, and achieve the effects of reducing calibration time, reducing emissions, and improving inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technology of the present invention is further described below:

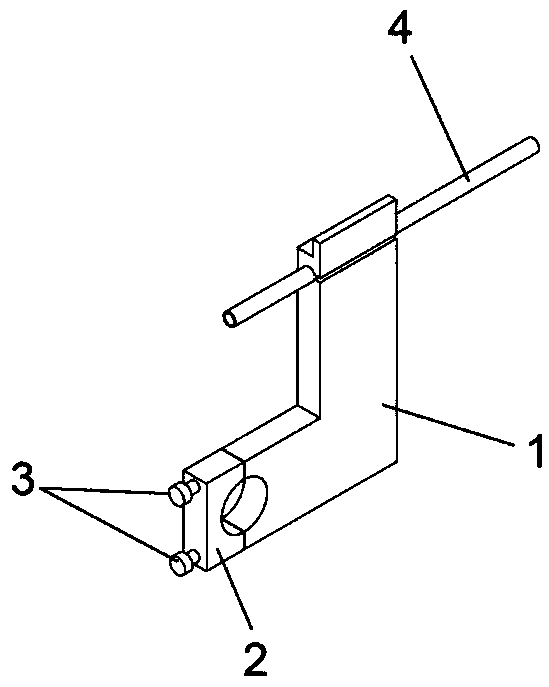

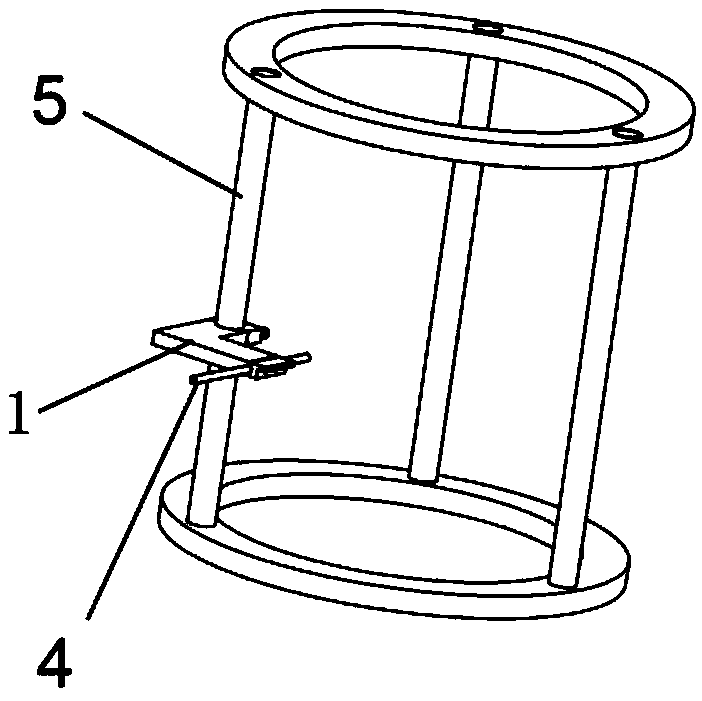

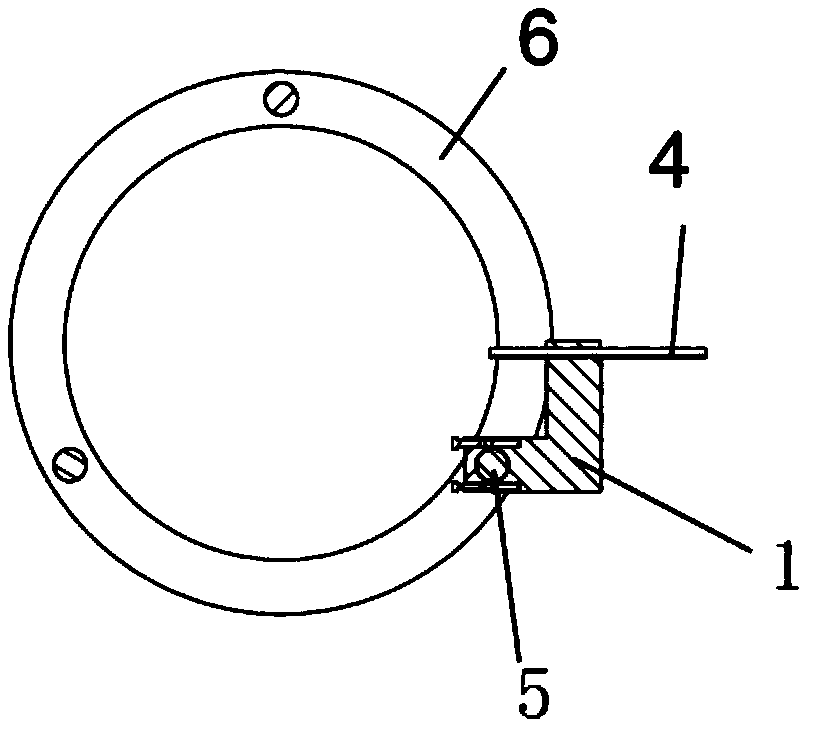

[0023] Such as Figure 1-3 As shown, a steam generator heat transfer tube eddy current inspection probe automatic calibration device, including: automatic calibration device main body 1, fixed locking block 2, locking screw 3 and calibration tube 4, one end of the automatic calibration device main body 1 There is a semicircular groove A, and the fixed locking block 2 is set on the semicircular groove A through a locking screw 3; the other end of the main body 1 of the automatic calibration device has a cylindrical through hole along the width direction of the main body of the device , the calibration tube 4 penetrates into the cylindrical through hole.

[0024] The main body 1 of the automatic calibration device is a right-angle plate structure, and the surface of the semicircular groove A is symmetrically provided with two threaded holes for screwing in the locking screws 3 .

[0025] The diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com