Air refractive index compensation method for laser tracking measurement system based on dual-wavelength interference

A dual-wavelength interference and laser tracking technology, applied in radio wave measurement systems, measurement devices, and re-radiation, etc., can solve the problems of cumbersome arrangement of multiple environmental parameter sensors, unable to ensure uniform distribution of air parameters, etc. Avoid cumbersome layout, widely used effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

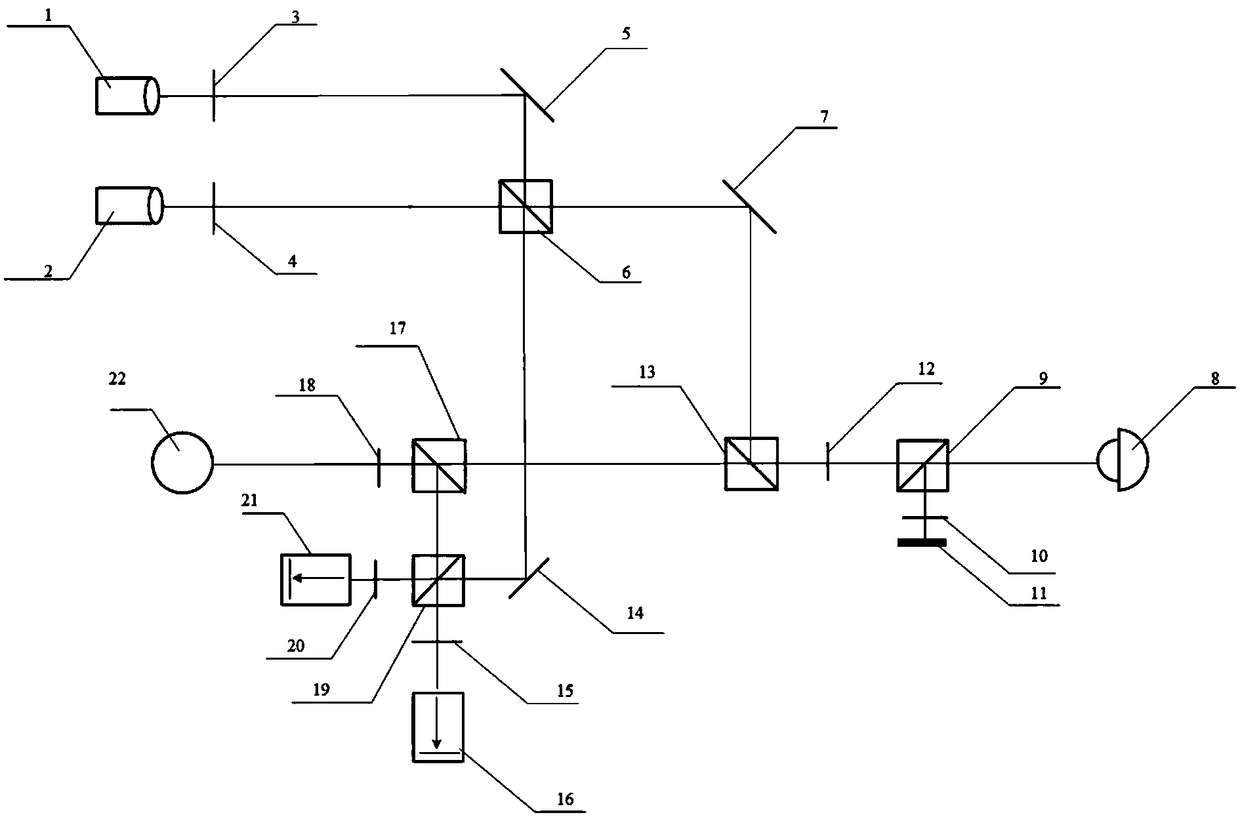

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] Such as figure 1 As shown, the output wavelength of single-frequency laser L1 and single-frequency laser L2 is λ 1 and lambda 2 The two lines of polarized light are adjusted by the analyzer P1 and the analyzer P2 respectively, so that the polarization direction is 45° to the optical axis. The wavelength is λ 1 After the linearly polarized light is reflected by the mirror R1, the wavelength is λ 2 The linearly polarized light converges at the beam splitter BS1 and separates them respectively, with a wavelength of λ 1 The transmitted light and the wavelength of the laser are λ 2 The reflected light of the laser is used as the reference light, and the wavelength is λ 1 The reflected light of the laser has a wavelength of λ 2 The transmitted light of the laser is used as the measurement light. The reference light is reflected by the mirror R3 and split by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com