Drilling parameter optimization method based on plastic energy dissipation ratio

A drilling parameter and plasticity technology, which is applied in electrical digital data processing, design optimization/simulation, special data processing applications, etc., can solve the problem that the cutting depth cannot be determined, the drilling efficiency cannot be further improved, and the optimal drilling parameters cannot be obtained. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] In order to make the object, technical scheme and advantages of the present invention more clear, the present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited.

[0095] A method for optimizing drilling parameters based on plastic energy consumption ratio, the method includes the following steps:

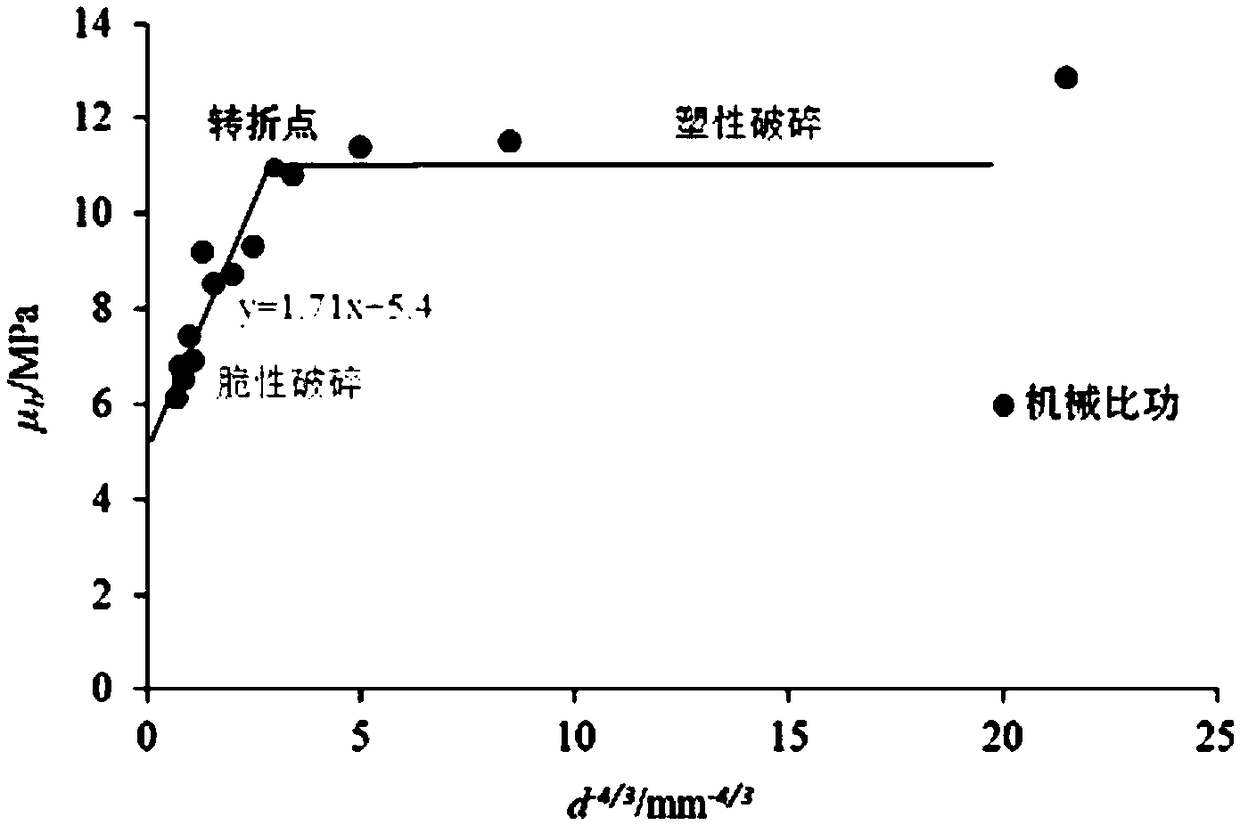

[0096] Step 1: According to the mechanical models of plastic crushing and brittle crushing in the drilling rock cutting process, respectively establish the calculation models of mechanical specific power in the case of rock plastic crushing and brittle crushing;

[0097] Step 2: Obtain the final calculation model of mechanical specific work by using the combination of mechanical specific work calculation models under the conditions of rock plastic crushing and brittle crushing;

[0098] Step 3: Establish a plastic energy consumption ratio calculation model based on the final calculation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com