Marine fire-resistant composite cable

A composite cable and fire-resistant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of weak anti-interference ability of cables, casualties and property, and disordered transmission signals, and achieve the promotion of stability, strong protection, and increased waterproofing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

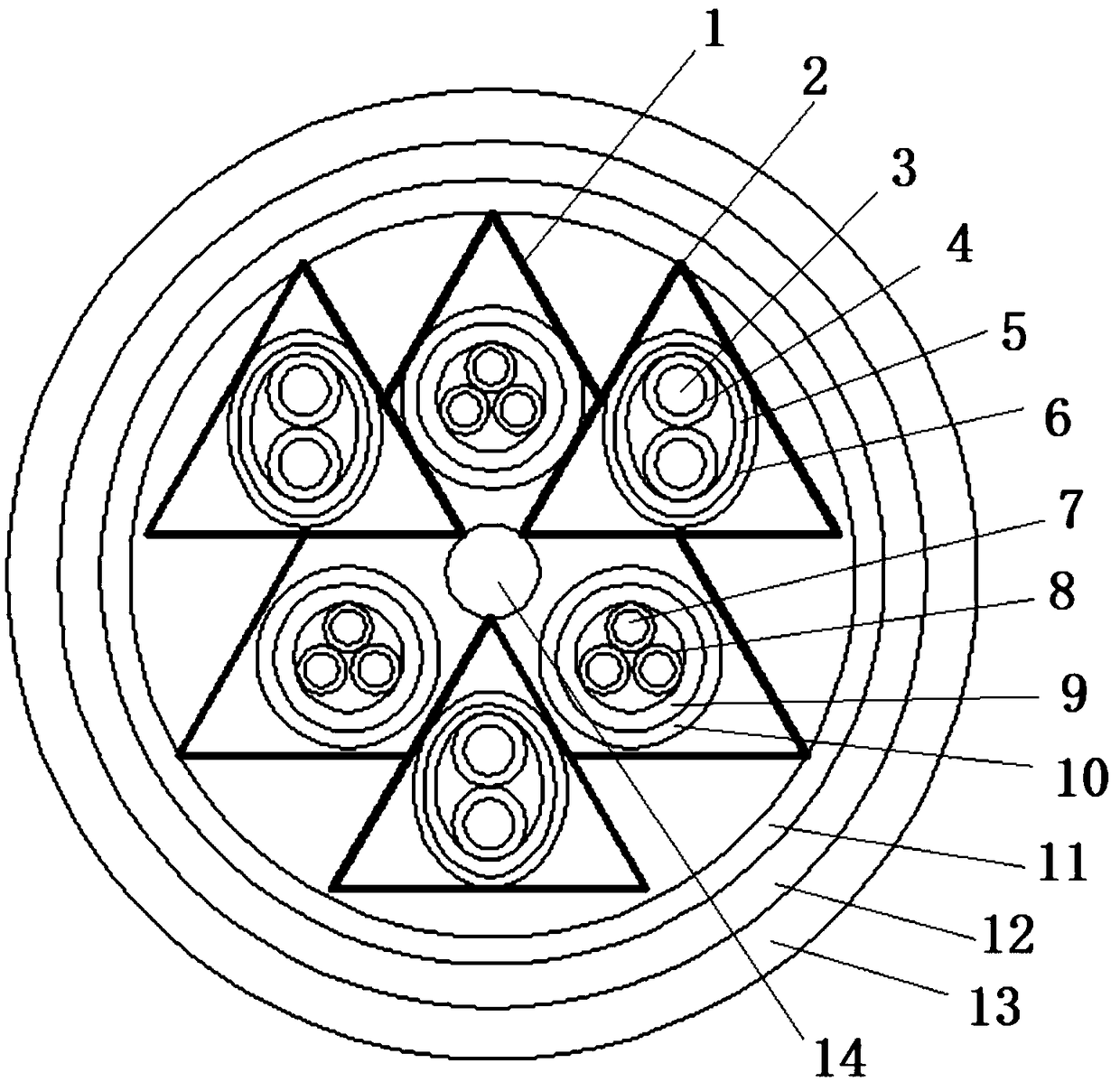

[0022] like figure 1 As shown, a marine fire-resistant composite cable includes a cable core, and the cable core includes a skeleton, and the skeleton includes a main skeleton 1 with a regular triangular cross-section and three sub-skeletons 2 with a regular triangular cross-section. The middle parts of the three faces of the frame 1 are slotted in the axial direction, and a sub-frame 2 is arranged in each groove, and the two cut surfaces of the groove are respectively clamped on the centerlines of two faces of the corresponding sub-frame 2 , The main frame 1 and the three sub-frames 2 are of an integrated structure; the three corners of the main frame 1 are respectively provided with a power wire core, and each sub-frame 2 is respectively provided with a control wire core, and the control wire The core includes two conductors 3, and each conductor 3 is respectively covered with a cross-linked polyethylene insulating layer 4 and twisted, and the two conductors 3 after twisting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com