A kind of basic zinc carbonate supercapacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors. It can solve the problems of high conductivity and achieve high specific capacitance, simple preparation methods, and environmentally friendly costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

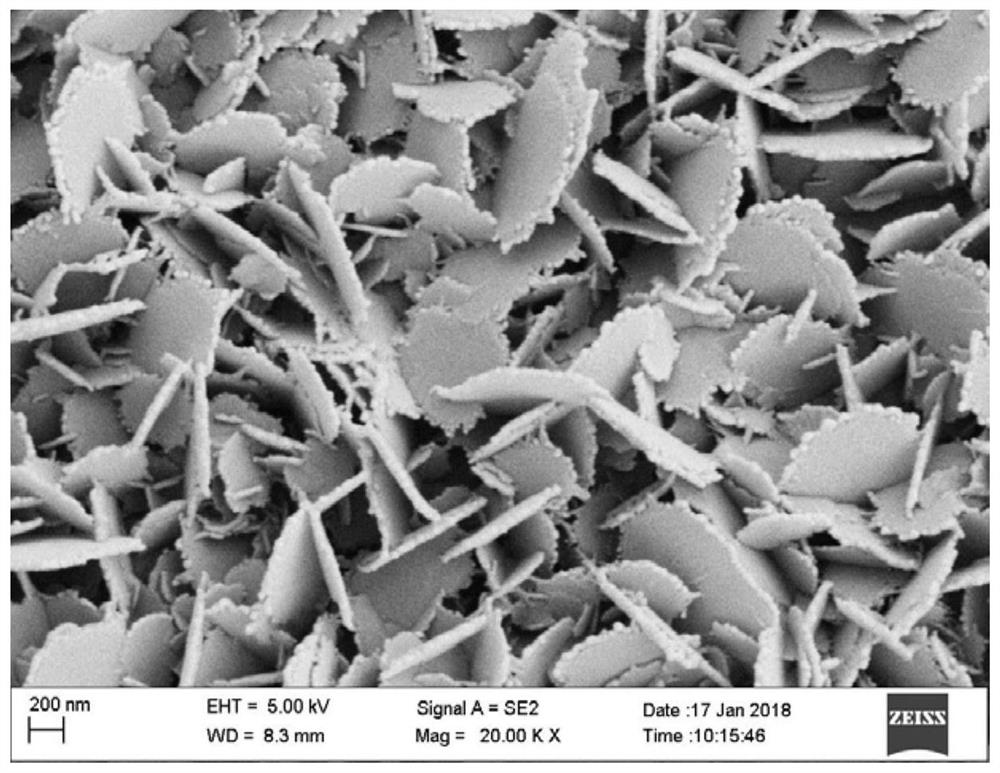

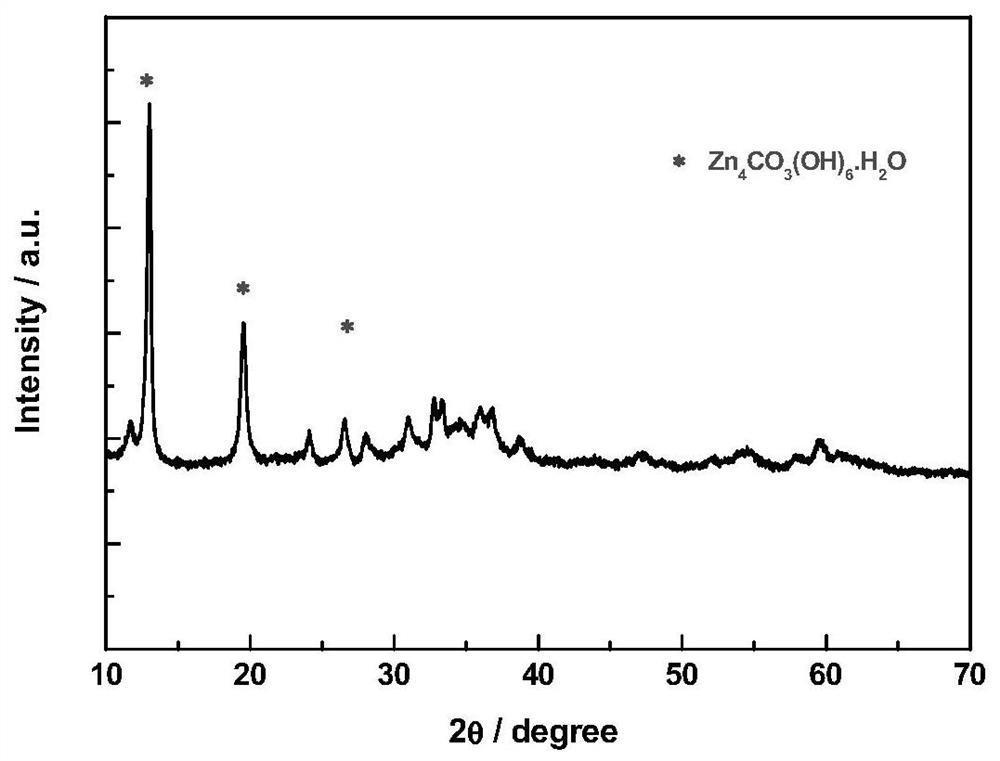

Image

Examples

Embodiment 1

[0026] A basic zinc carbonate supercapacitor electrode material and a preparation method thereof are implemented according to the following steps.

[0027] (1) Soak nickel foam in hydrochloric acid with a concentration of 2mol / L for 10 minutes, remove the surface oxide film, wash with deionized water until neutral and dry;

[0028] (2) Take zinc nitrate, aluminum nitrate and urea to prepare a mixed solution. The concentration of zinc nitrate in the solution is 0.01mol / L, the concentration of aluminum nitrate is 0.002mol / L, and the molar concentration of urea is 0.06mol / L.

[0029] (3) Put the treated nickel foam into the mixed solution of step (2) and sonicate for 10 minutes. The volume ratio of nickel foam to the above mixed solution is 1:3.

[0030] (4) Put the mixed solution and nickel foam into the reactor for hydrothermal treatment; the volume ratio of nickel foam to etching solution is 1:3, the hydrothermal temperature is 120°C, and the hydrothermal time is 2 hours.

...

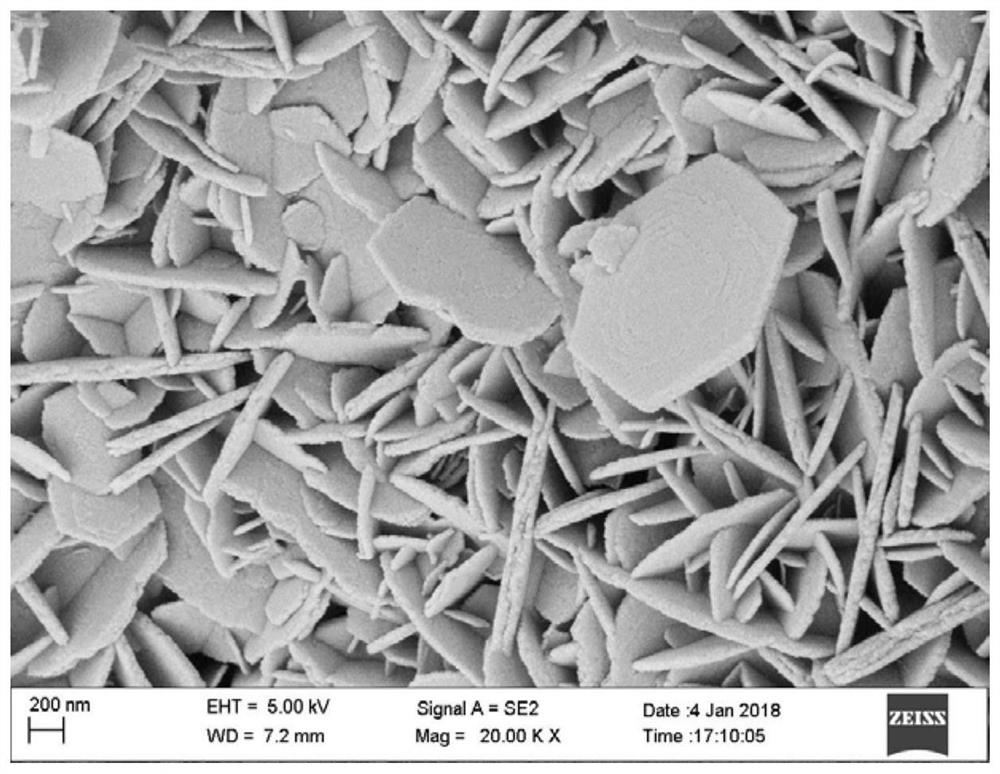

Embodiment 2

[0034] A basic zinc carbonate supercapacitor electrode material and preparation method thereof, the steps are the same as in Example 1, except that in step (4), the hydrothermal time is 8 hours. Figure 5 Cyclic voltammetry curves of the in situ growth basic zinc carbonate material on the surface of the prepared nickel foam at different scan rates. The test process is a three-electrode system. The saturated calomel electrode is used as the reference electrode, the platinum electrode is used as the counter electrode, and the prepared composite electrode is used as the working electrode. The electrolyte is 6M KOH. When the scanning speed is 50mV / s, the specific capacitance Up to 1100F / g.

Embodiment 3

[0036] A basic zinc carbonate supercapacitor electrode material and a preparation method thereof, the steps are the same as in Example 1, except that in step (4), the hydrothermal time is 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com