Output driving circuit

A technology for outputting drive circuits and output stages, applied to electrical components, electronic switches, generating electrical pulses, etc., can solve problems such as high cost and large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with each embodiment, the technical solution of the present invention is clearly and completely set forth, but described embodiment is only the embodiment that the present invention is used for describing description and not all embodiments, based on these embodiments, this invention The solutions obtained by those skilled in the art without creative work all belong to the protection scope of the present invention.

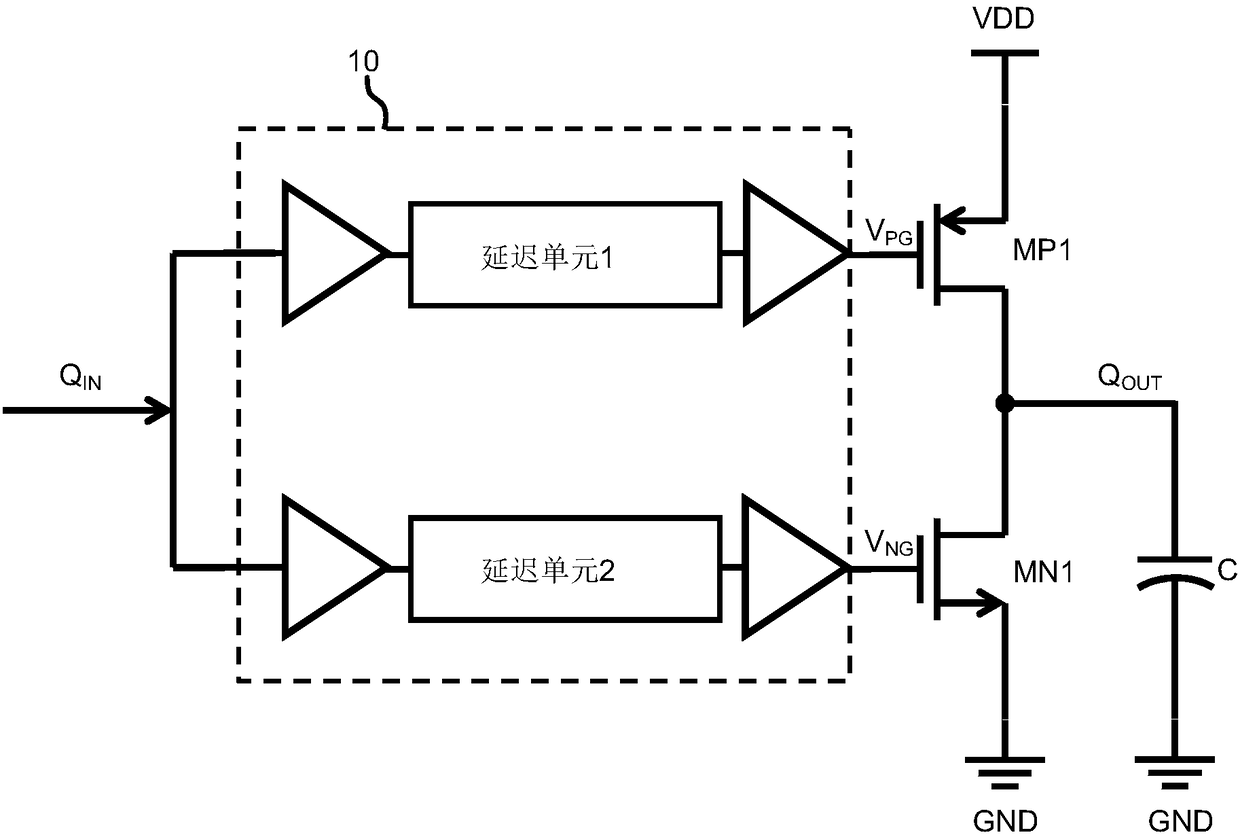

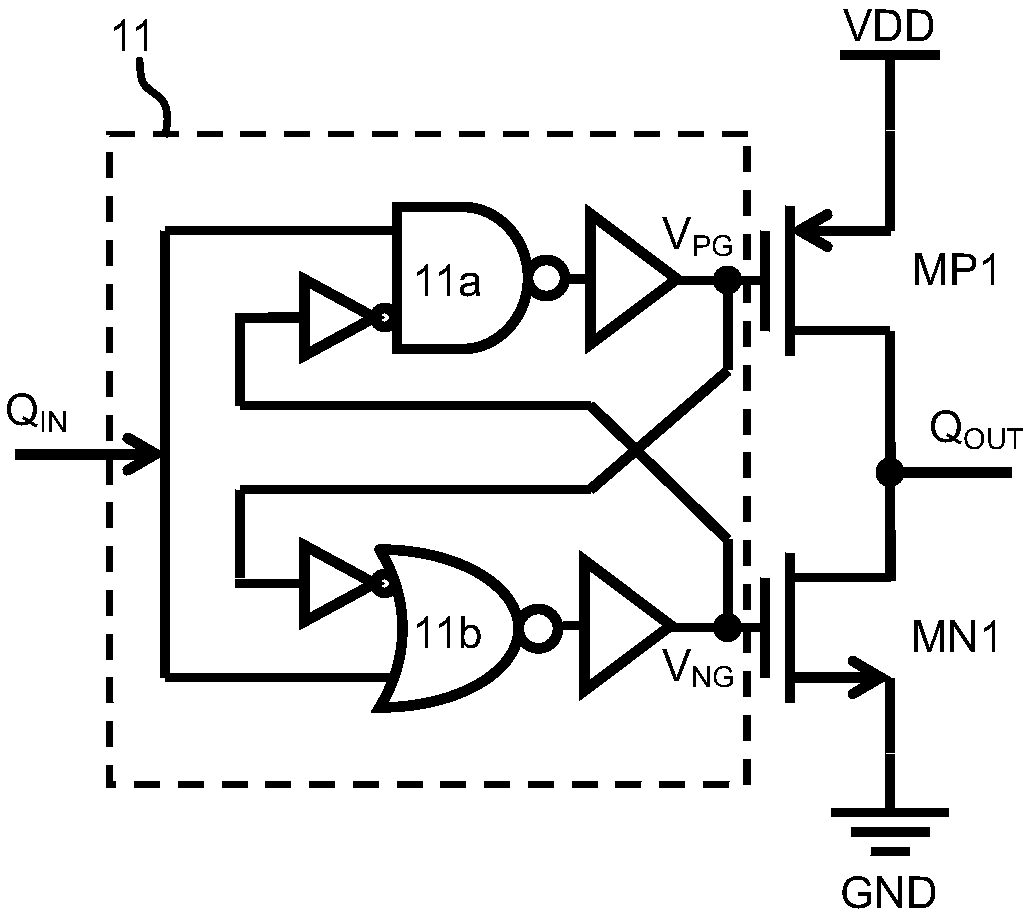

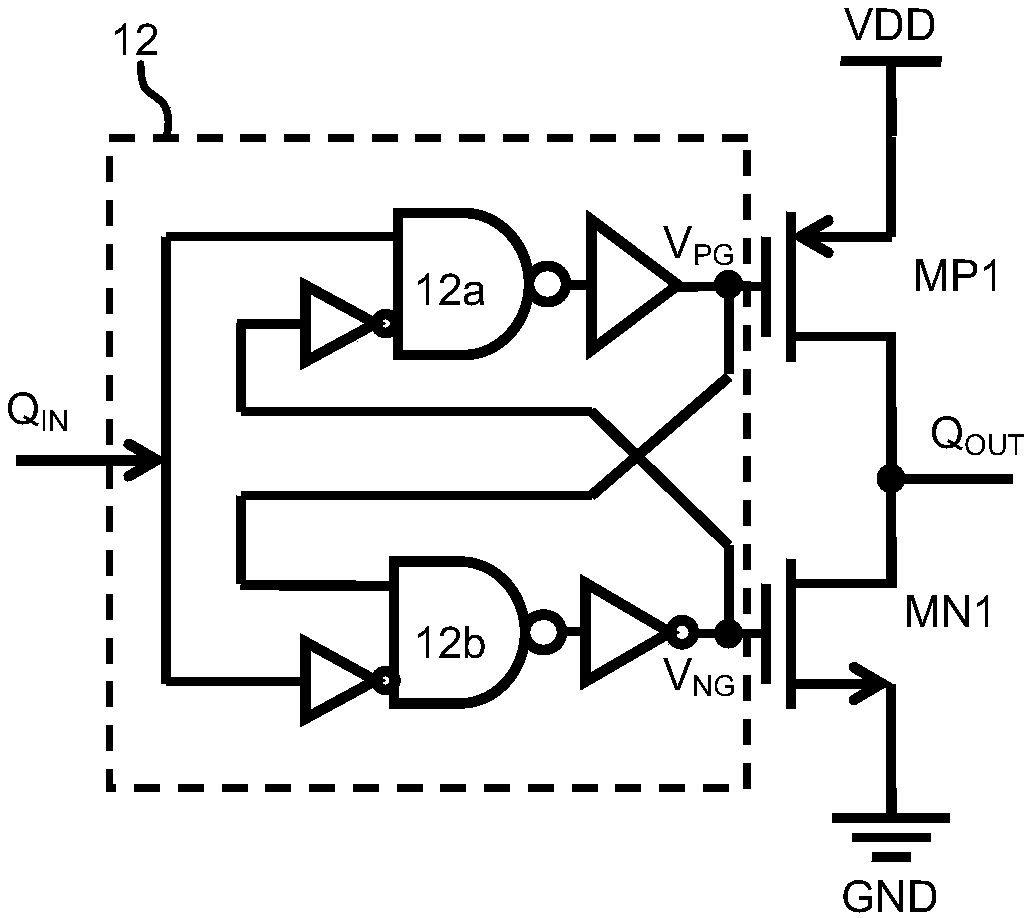

[0024] In order to have a deeper understanding of the spirit of the invention of this application, we first explain Figure 1 to Figure 3 The traditional implementation that uses more components and parts can realize the delay, and then compares the present invention with the Figure 4 A time-delay implementation that can greatly reduce the number of components is shown in .

[0025] see figure 1 , receiving an input signal Q IN The pre-stage driver 10 includes two control branches, the first control branch includes a delay unit 1 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap