Rotating device capable of connecting double accessory heads

A technology of a rotating device and an attachment head, applied in the field of moving arms, can solve the problems of unhealthy physical and mental health, high cost, and difficulty in implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

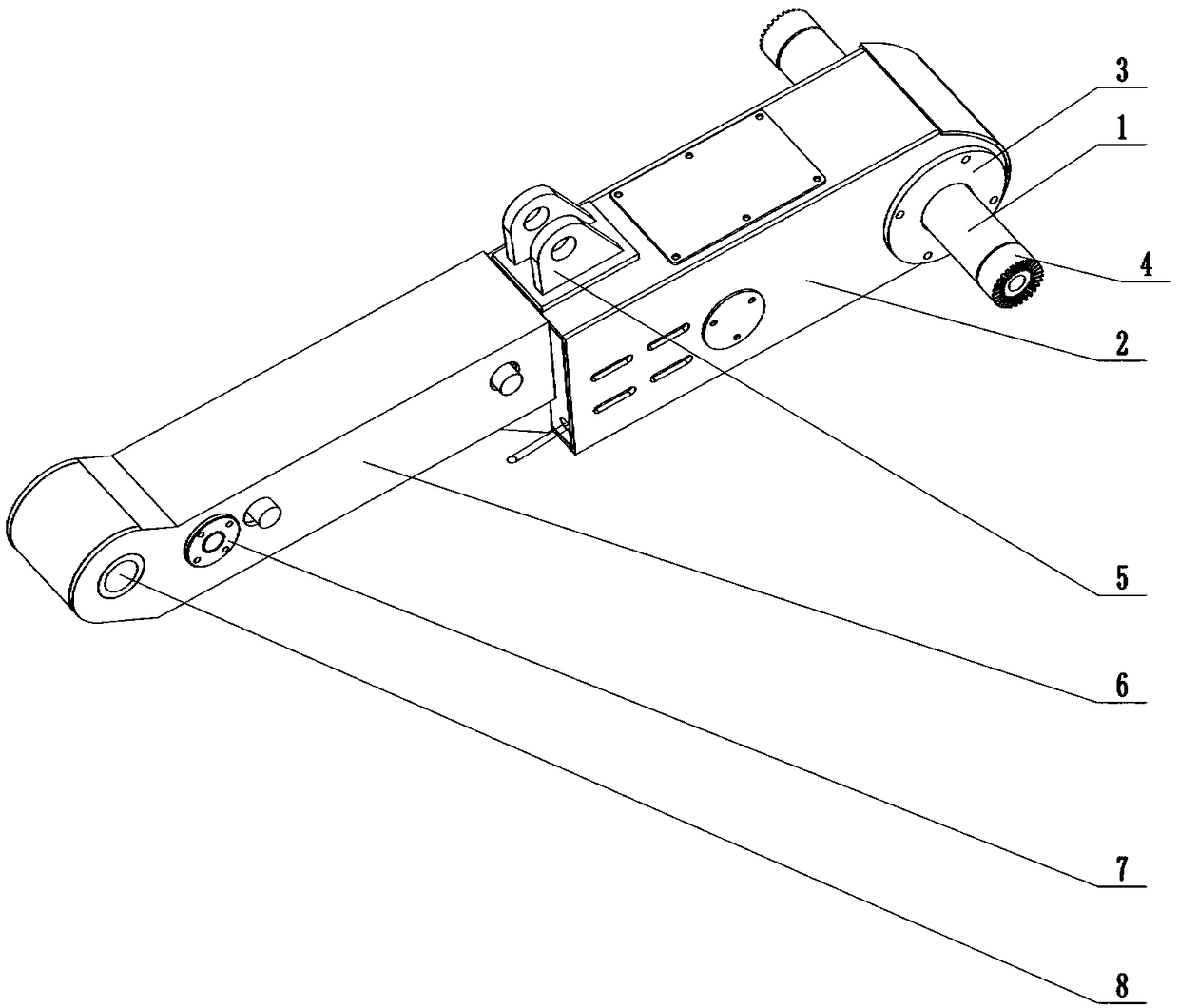

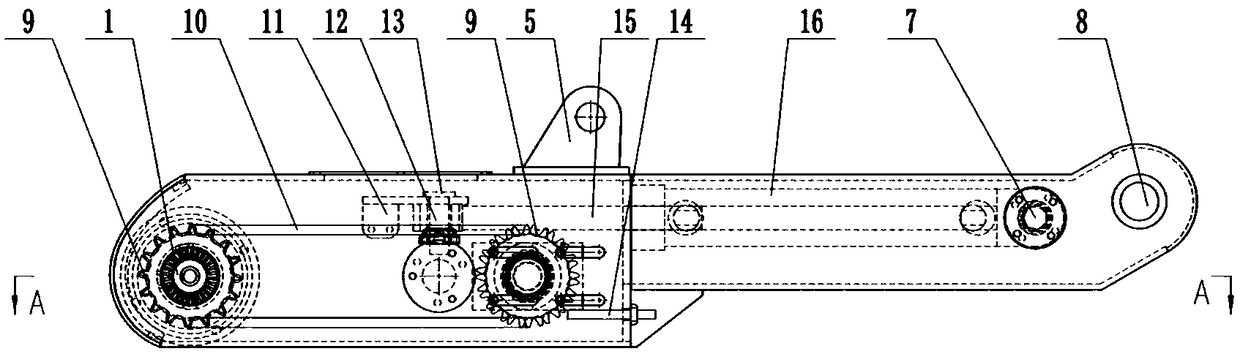

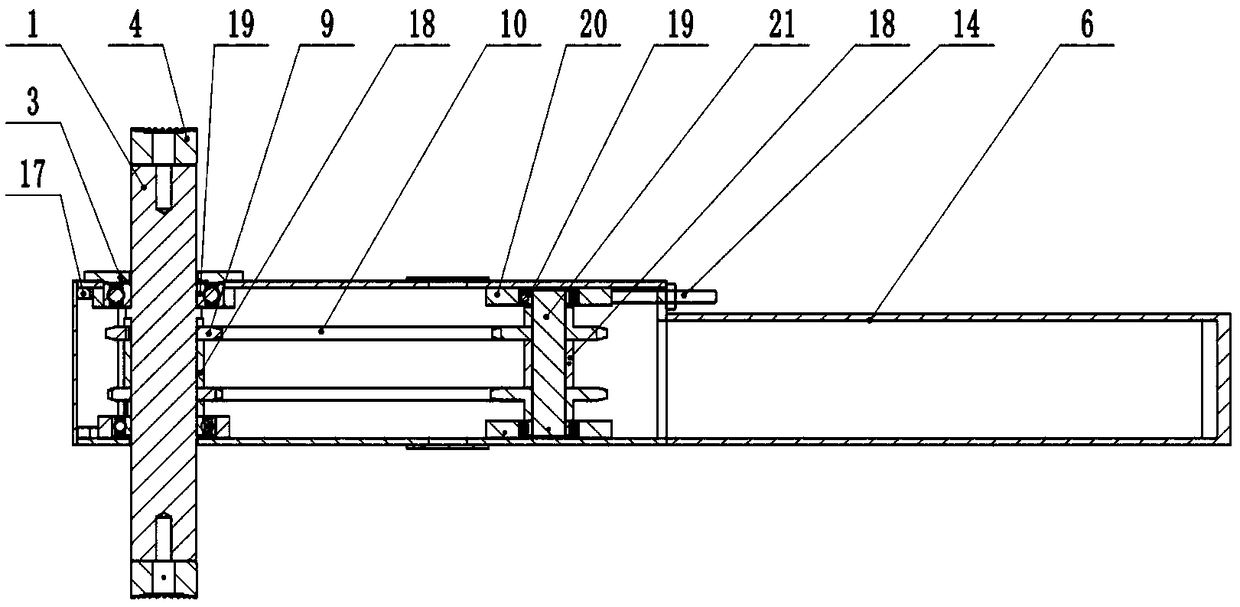

[0029] A double-attachment head rotating device that can be connected, including a movable arm casing, a hydraulic cylinder and a sprocket 9. The movable arm casing is formed by connecting the cylinder section casing 6 and the chain section casing 2. The two inner walls of the head end of the chain section casing 2 are connected The corresponding position is fixed with a deep groove bearing 19 through the welding structure 17 in the chain segment shell 2, and a rotary shaft 1 is arranged through the two deep groove bearings 19, and the two ends of the rotary shaft 1 protrude from the chain segment shell 2, and the rotary shaft 1 Two sprockets 9 are arranged symmetrically on the axial section between the two deep groove bearings 19, and bearing housings 20 are arranged at corresponding positions on the inner side walls of the tail end of the chain segment shell 2, and the deep groove bearings 19 are fixed on the bearing housings 20. The sprocket adjustment shaft 21 is fixed betw...

Embodiment 2

[0039]A double-attachment head rotating device that can be connected, including a movable arm casing, a hydraulic cylinder and a sprocket 9. The movable arm casing is formed by connecting the cylinder section casing 6 and the chain section casing 2. The two inner walls of the head end of the chain section casing 2 are connected The corresponding position is fixed with a deep groove bearing 19 through the welding structure 17 in the chain segment shell 2, and a rotary shaft 1 is arranged through the two deep groove bearings 19, and the two ends of the rotary shaft 1 protrude from the chain segment shell 2, and the rotary shaft 1 Two sprockets 9 are arranged symmetrically on the axial section between the two deep groove bearings 19, and bearing housings 20 are arranged at corresponding positions on the inner side walls of the tail end of the chain segment shell 2, and the deep groove bearings 19 are fixed on the bearing housings 20. The sprocket adjustment shaft 21 is fixed betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com