Assembled internal-covering heat-preservation sunlight greenhouse

A solar greenhouse, assembled technology, applied in the agricultural field, can solve the problems of easy water accumulation, soil erosion, poor reliability of roll film and air release, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

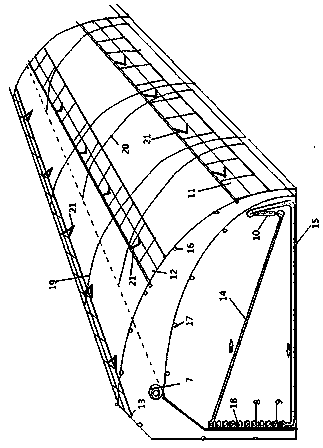

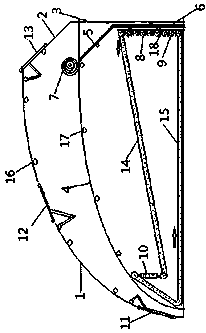

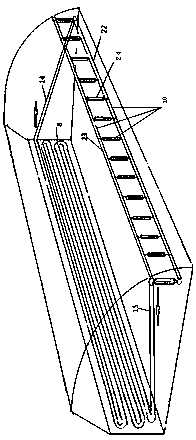

[0027] Embodiment one: see figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , an assembled inner-covered heat-preservation solar greenhouse according to the present invention, comprising an external lighting device, an internal heat preservation device and an internal heat storage device arranged sequentially from the outside to the inside, and the external lighting device includes an outer front roof fixedly arranged on the ground 1 and the outer rear facade wall 3, and the outer rear roof 2 arranged between the rear end of the outer front roof 1 and the top end of the outer rear facade wall 3, the outer front roof 1, the outer rear roof 2 and the outer rear The facade wall 3 includes an external support framework 19 that plays a supporting role and a transparent material covered on the external support framework 19. The internal heat preservation device includes an inner front roof 4 and an inner rear facade wall 6 fixed on the ground, a...

Embodiment 2

[0038] Embodiment two: see figure 1 , figure 2 , Figure 4 ,, Figure 5 , Figure 6 , Figure 7 and Figure 8 , an assembled inner covered heat preservation solar greenhouse of the present invention, the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The width of the ventilation window 12 in the middle of the outer front roof and the ventilation window 13 of the outer rear roof is 100 cm. The lower ventilation window 11 of the outer front roof is a top-hung window structure, and the window opening angle of the lower ventilation window 11 of the outer front roof is 45 °. The ventilation window 12 in the middle part of the outer front roof is a top-hung window structure, and the window opening angle of the ventilation window 12 in the middle part of the outer front roof is 42°. The window opening angle of 13 is 45°, the sagittal height of the outer support frame 19 is 6.0 meters, the north-south span ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com