Multi-flavor fresh corn double-transmission type steaming and baking method

A fresh corn, double-transmission technology, applied in the field of multi-taste fresh corn double-transmission steaming and roasting, can solve the problems of difficult control of the degree of roasting and uneven roasting of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The multi-taste fresh corn double-drive steaming and roasting method involved in this embodiment mainly includes five steps: loading of fresh corn, setting of steaming and roasting parameters, steaming of fresh corn, exhausting steam from the oven, and roasting of fresh corn. The process steps are as follows:

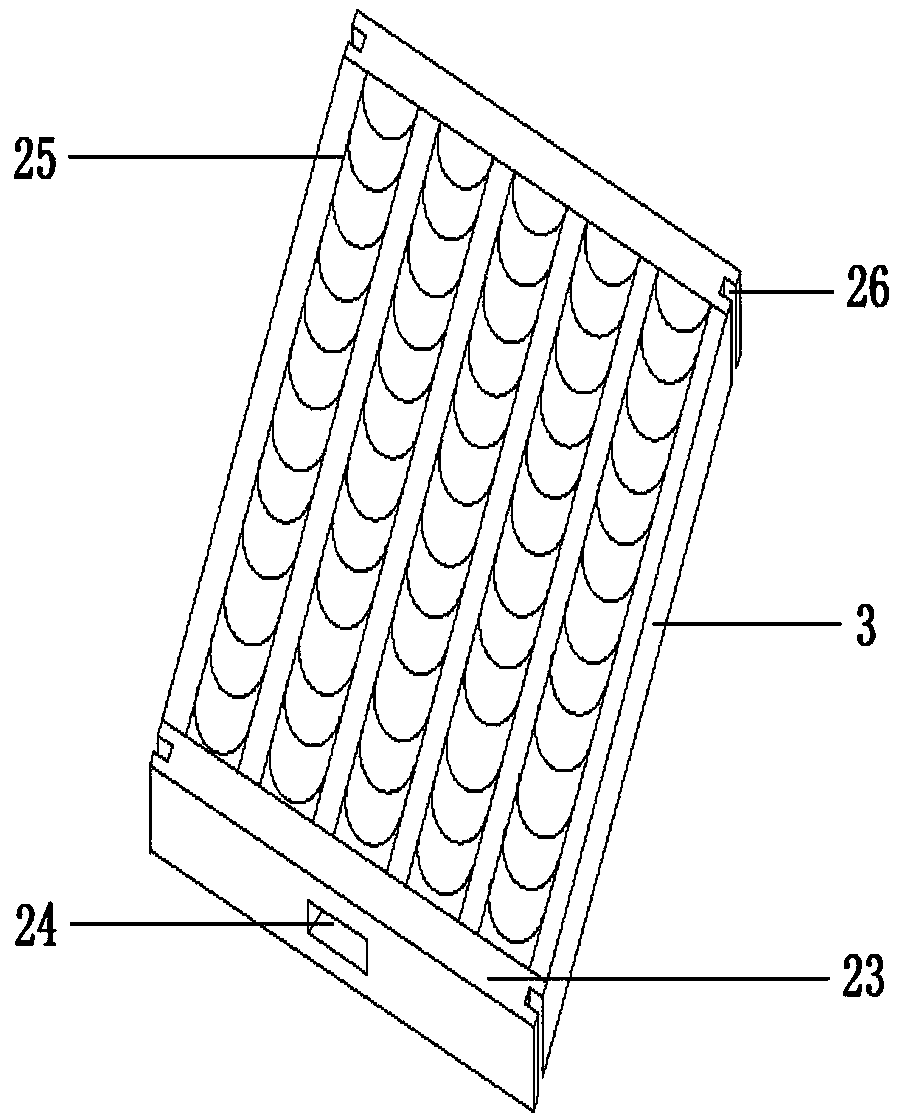

[0044] (1) Loading of fresh corn: open the oven door 6, pull out the cage drawer 3 from the oven 5, place the fresh corn in the single drawer groove 35, close the single drawer cover 34, open the single drawer lock 29, push the cage drawer 3 Put it into the oven 5, close the oven door 6, insert the transmission belt 15 into the transmission belt groove 26, open the steamer door 7, pull out the steamer 8, add cooking liquid 55, the volume of the cooking liquid 55 is 2 / 3 of the volume of the steamer 8 , push the steam box 8 back to the box body 1, and close the steam box door 7;

[0045] (2) Steaming and roasting parameter setting: start the multi-taste fresh corn...

Embodiment 2

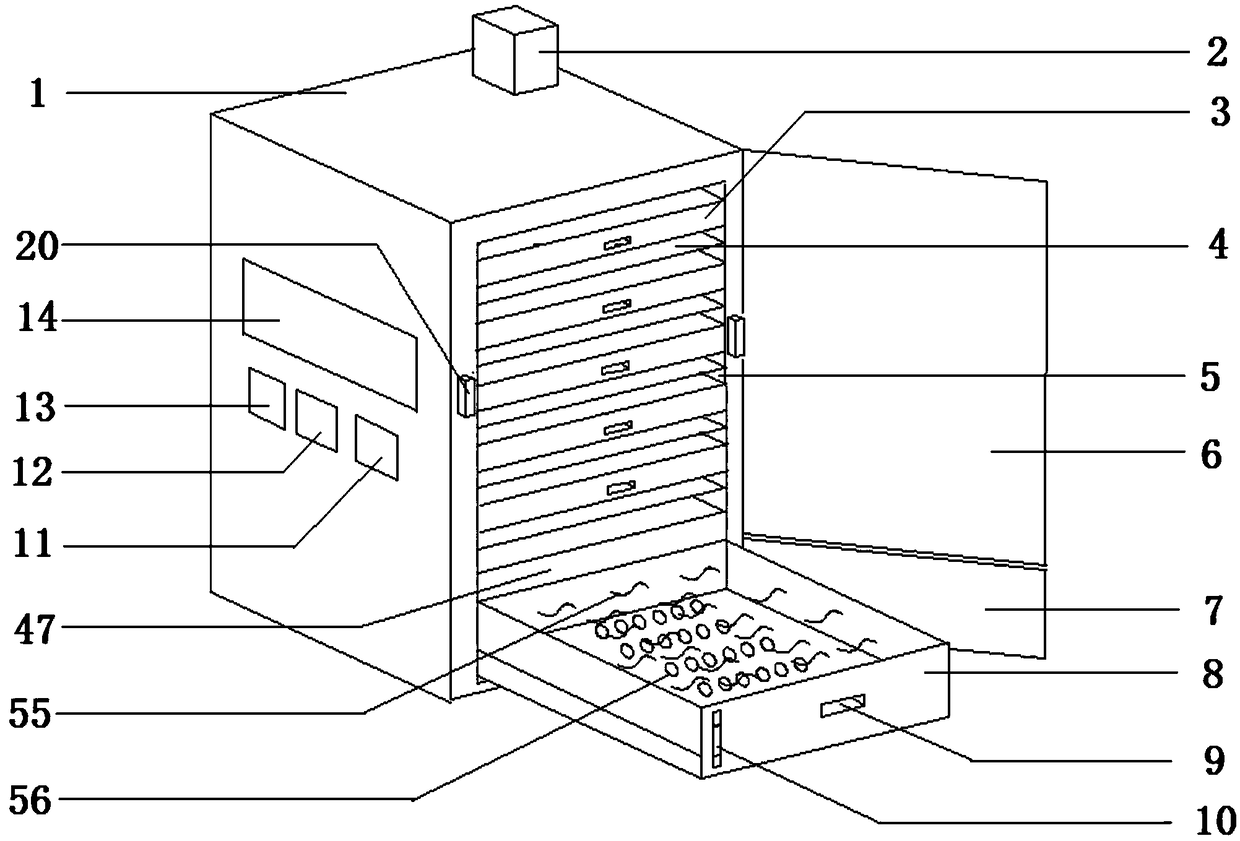

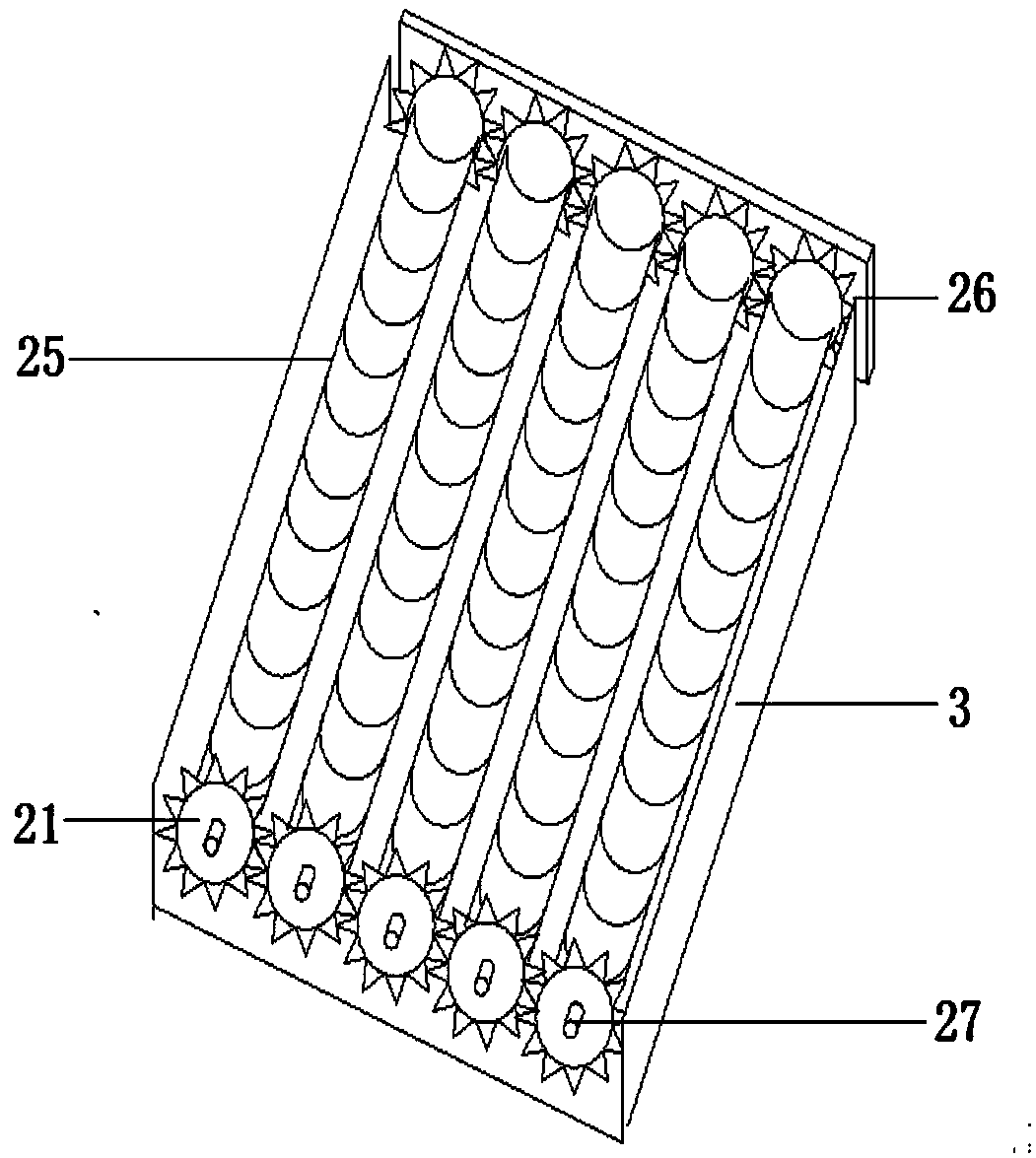

[0052] The multi-taste fresh corn double-transmission steaming and roasting device involved in Example 1 has a main structure including a box body 1, an exhaust device 2, a cage drawer 3, a heating plate 4, an oven 5, an oven door 6, a steamer door 7, a steamer Box 8, steam box handle 9, liquid level gauge 10, steam box controller 11, exhaust controller 12, oven controller 13, display 14, transmission belt 15, oven motor 16, rotating shaft 17, drive wheel 18, upper drive wheel 19 , control button 20, cage wheel 21, lower drive wheel 22, cage shell 23, cage handle 24, single drawer 25, drive belt groove 26, round shaft 27, drawer lock spring 28, single drawer lock 29, lock lever 30, single drawer Cover 31, cover rod 32, drawer rod 33, lock hole 34, single drawer groove 35, rotating ladder 36, expansion button 37, expansion spring 38, reverse rotating ladder 39, limit ring 40, limit spring 41, switch limit Slot 42, extension arm limit slot 43, extension arm 44, extension wheel 4...

Embodiment 3

[0059] The control process of steaming and roasting is realized by using the multi-taste fresh corn double-transmission steaming and roasting device involved in embodiment 2: the control unit composed of steam box controller 11, exhaust steam controller 12, oven controller 13 and display 14 passes electrical information Connected to implement full automatic control of steaming and roasting fresh corn, wherein the steam box controller 11 is used to control the conversion motor 49 and the first heating plate 56 in the steam box 8; the exhaust steam controller 12 is used to control the conversion motor 49 and the steam exhaust device 2. The oven controller 13 is used to control the oven motor 16 and the heating plate 4 in the oven 5; the display 14 is used to display the time and temperature values of the steam oven controller 11, exhaust steam controller 12, and oven controller 13; specific control The process is:

[0060] (1) The steam box controller 11 sends a clockwise rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com