Automatic food quantitative stuffing-dividing machine

A quantitative filling and food filling technology, which is applied in the field of automatic food quantitative filling machine, can solve the problems of reducing work efficiency, affecting food taste, surplus, etc., and achieves free adjustment of filling speed, good promotion and application value, and real-time filling number statistical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

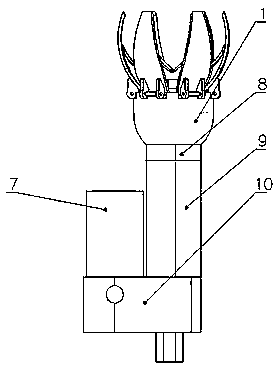

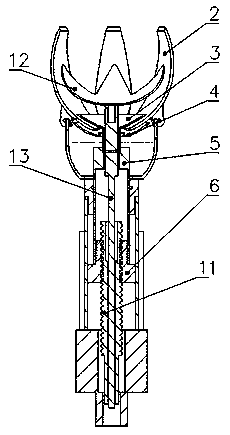

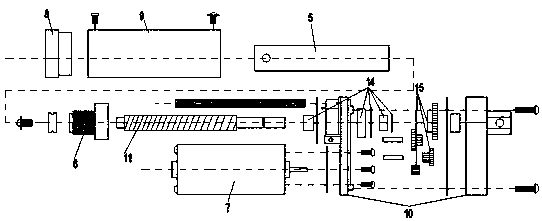

[0018] refer to Figure 1-4 , an automatic food quantitative stuffing machine, including an electric push rod, a hemispherical housing 1 gear box assembly 10 and a motor 7, one end of the hemispherical housing 1 is fixedly connected with a cover 8, and the edge of the other end is hinged equidistantly. A plurality of petal grasping pieces 2, the number of petal grasping pieces 2 is 4-12, and the petal grasping pieces 2 are closed to form a spherical or ellipsoidal airtight structure, and the mechanism formed by multiple petal grasping pieces 2 is provided with Silicone flower piece 12, the petals of the silicone flower piece 12 and the petal grasping piece 2 are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com