Soil remediation equipment and working method thereof

A soil remediation and soil technology, applied in the field of soil remediation, can solve the problems of long soil remediation cycle, unfavorable large-scale promotion, high soil remediation cost, and achieve the effects of complete removal of organic matter, convenient operation and high heating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

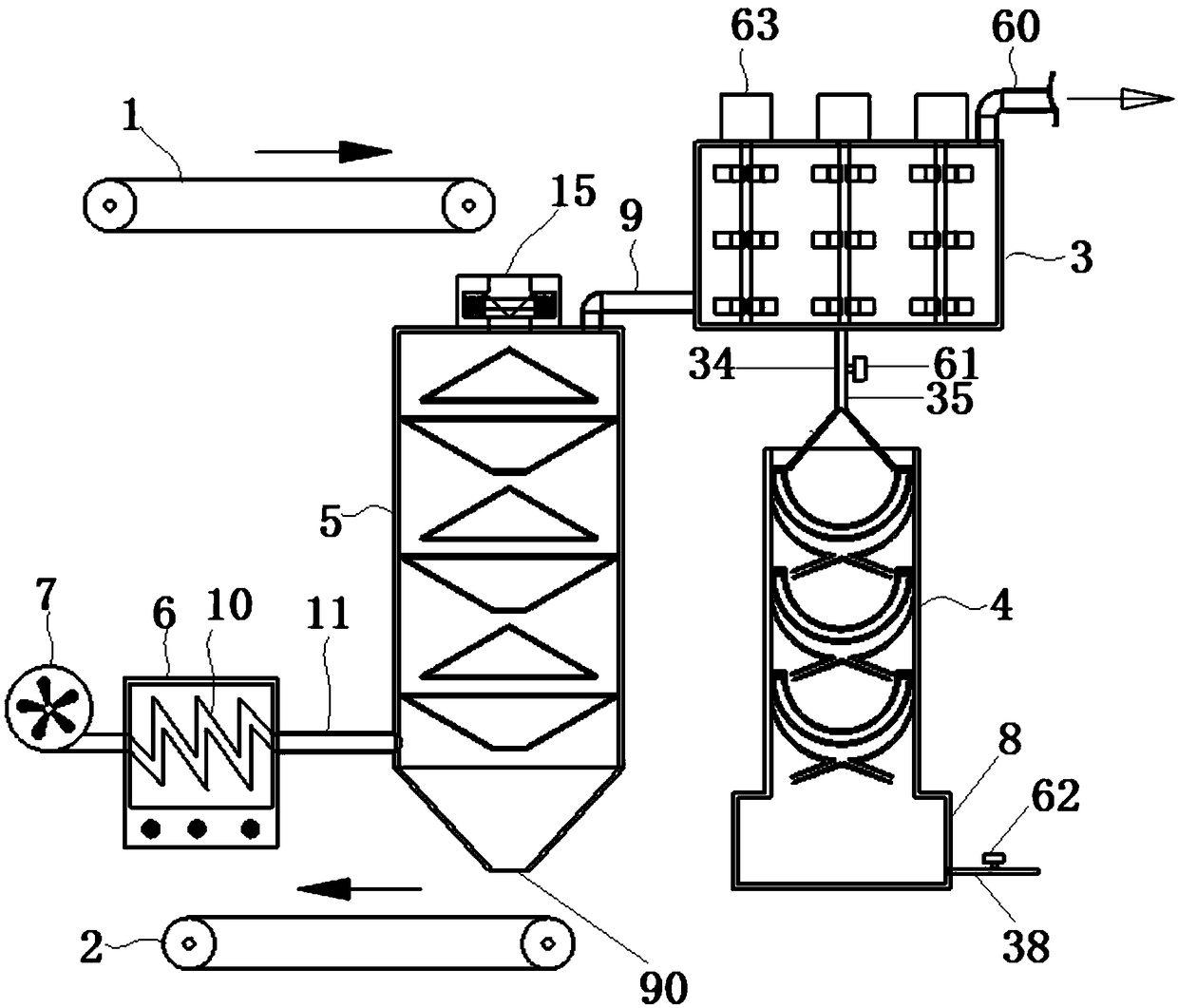

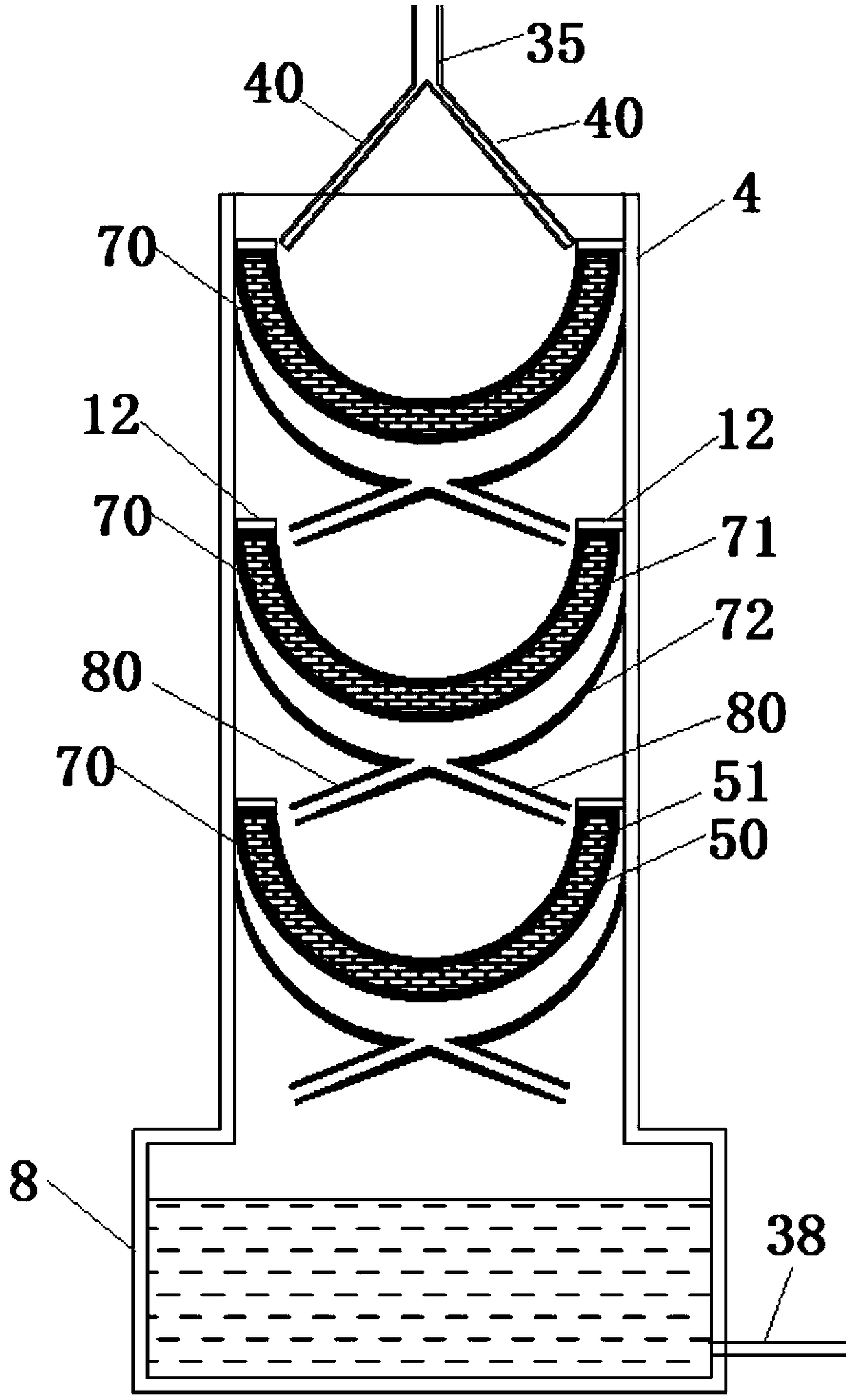

[0038] as attached figure 1 As shown, a kind of soil remediation equipment comprises soil input belt conveyor 1, soil output belt conveyor 2, microwave heating container 5, gas pollutant removal stirring water tank 3 and sewage filtration adsorption box 4;

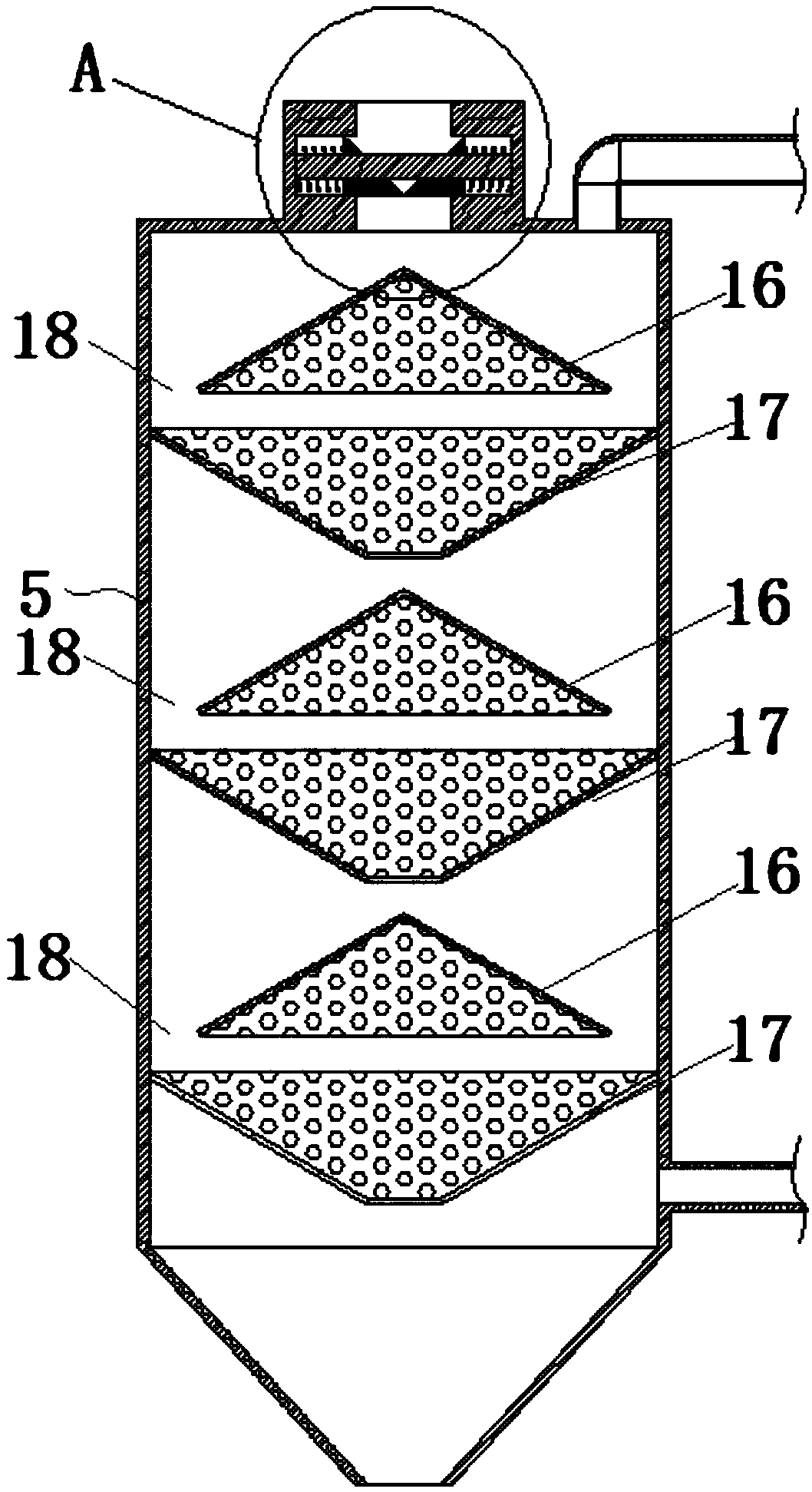

[0039] The microwave heating container 5 has a feed port 15 and a discharge port 90, the soil input belt conveyor 1 is correspondingly arranged on the feed port 15 of the microwave heating container 5, and the soil output belt conveyor 2 is correspondingly arranged on the microwave heating container 5. The discharge port 90 of the heating container 5, the microwave heating container 5 can heat and repair the soil transported therein by the soil input belt conveyor 1, and the microwave heating container 5 is provided with several holes for soil rolling and diversion. The positive conical soil deflector 16 and sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com